Reliable Supplier Precision Metal Forging

Frequently Used Custom Metal Forgin parts

PRIME builds precision Casting parts to the highest standards of strength, reliability, and customization

Connecting Rods

Applications: Passenger Car Engines, Commercial Vehicle Power Units, High-Performance Racing Engines

Industry Intro:

The automotive industry requires connecting rods with high tensile strength, precise geometry

Syringe Barrels

Applications: Oilfield PDC Drill Bit Bodies, Tricone Bit Bodies, Directional Drilling Bit Cores

Industry Intro:

The oil and gas drilling industry requires drill bit bodies engineered for extreme downhole conditions.

Gear

Applications: Machine Tool Gear Assemblies, Conveyor Drive Gears, Industrial Robotics Gear Systems

Industry Intro:

The industrial machinery sector requires gears with high wear resistance, precise tooth geometry.

Axles

Applications: Rail Transit Axles, High-Speed Train Axle Assemblies, Freight Wagon Axle Systems

Industry Intro:

The rail industry demands axles that deliver extreme durability and consistent performance under heavy loads .

Construction Structure

Applications: Excavator Engine Crankshafts, Mobile Crane Crankshafts, Mining Vehicle Crankshafts

Industry Intro:

The construction and heavy equipment industry requires crankshafts that can withstand extreme shock loads.

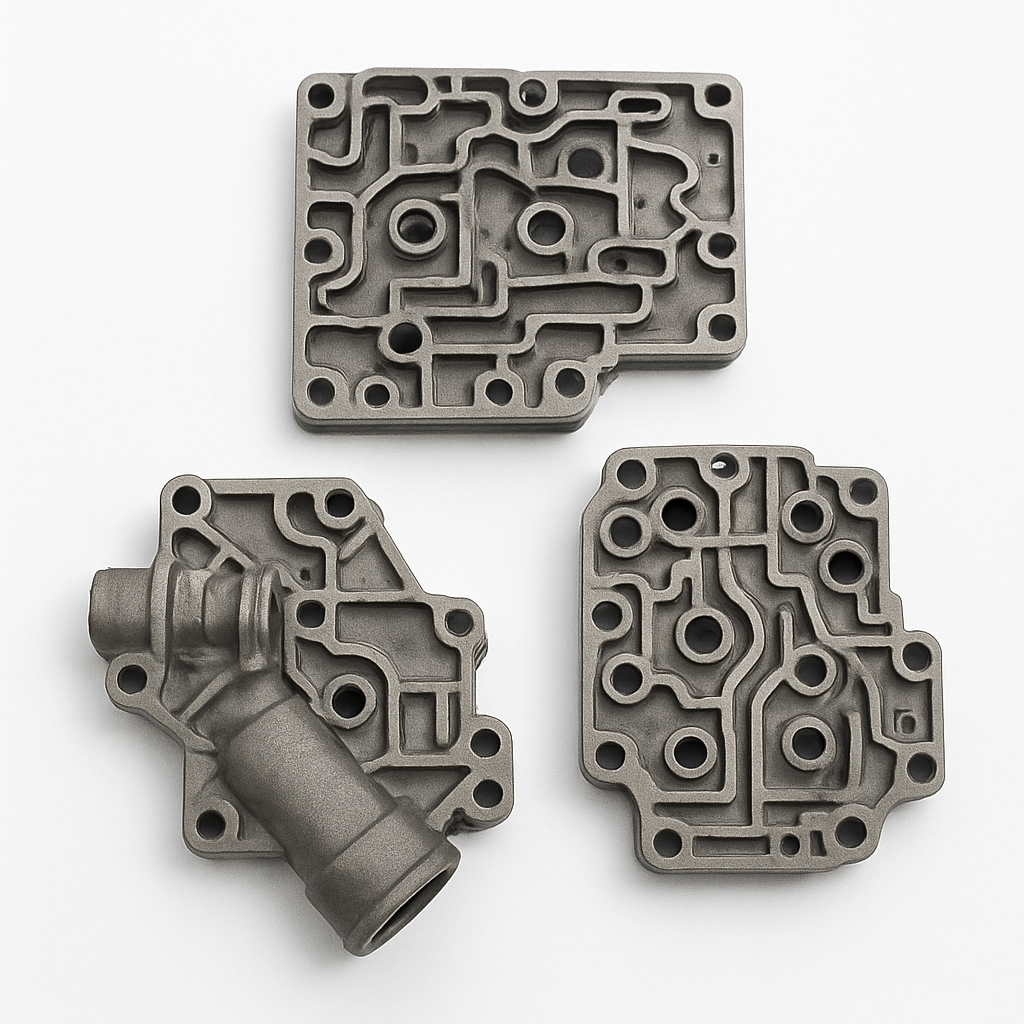

Flow Control Valve

Applications: Municipal Water Supply Flow Control Valves, Wastewater Treatment Flow Valves

Industry Intro:

The water management industry requires flow control valves that deliver precise regulation, corrosion resistance.

What Makes PRIME Your Optimal Forging Partner?

More than a supplier, PRIME is a strategic partner in your success. We ensure your components achieve unparalleled strength and precision, while fortifying your supply chain. Leverage our decades of experience, ISO-certified excellence, and comprehensive forging capabilities for a seamless, global partnership.

- 30+ Years of Manufacturing Expertise: Since 1993, we’ve been producing high-quality bolts, screws, nuts, rivets, and specialty fasteners for global industries

- ISO 9001:2015 Certified Quality: Every batch is rigorously inspected to ensure consistent strength, dimensional accuracy, and surface treatment integrity.

- Customizable Materials and Standards: We offer fasteners in carbon steel, stainless steel, brass, and more—meeting DIN, ANSI, ISO, and client-specific requirements.

"Need a Fastener That Actually Meets Your Specs?"

Submit your drawings, specs, or samples for a fast response. Our engineers will provide material recommendations, technical analysis, and a competitive quote within one business day. Partner with PRIME to get the quality, durability, and reliable service your supply chain requires.

Customized metal fasteners are essential core components in modern industrial systems, widely applied in critical sectors such as construction, automotive, energy, and machinery manufacturing. At Prime, we provide tailored fastening solutions using high-precision metalworking

Custom-Engineered Metal Forging for High-Stakes Applications

Forged metal parts form the backbone of critical systems across hydraulic and pneumatic equipment, heavy construction machinery, petrochemical processing plants, rail and marine transportation, and industrial automation. These high-strength components deliver essential structural integrity for applications requiring extreme load-bearing capacity, pressure containment, and long-term durability under harsh operating conditions. At Prime Forge Technologies, we specialize in manufacturing precision forged solutions that combine superior material density with optimized grain flow characteristics, ensuring exceptional fatigue resistance and impact strength.

Forged Metal Parts FAQ: Your Questions Answered

We’ve collected answers to frequently asked questions to help you better understand our forged metal parts solutions, from material selection and dimensional tolerances to export packaging and worldwide delivery.

PRIME forges a wide range of metals to meet diverse application needs, including robust carbon steels (C45, 1045), high-strength alloy steels (42CrMo, 4140), and corrosion-resistant stainless steels (304, 316, 410). We also work with lightweight aluminum and non-ferrous options like brass. Full material certification and traceability are standard to ensure quality and compliance.

Dimensional accuracy for as-forged parts is typically within ISO standard limits of ±0.3 mm to ±1.0 mm. When your design demands precision beyond forging capabilities, our value-added machining centers deliver finished features to micron-level tolerances of ±0.01 mm.

Closed die forging enables higher precision and complex shapes with better surface finish. Open die forging is ideal for larger, simpler parts with superior grain flow and strength. We help you select the right process based on part size, material, and application.

Yes. Our capabilities extend beyond forging to provide a complete finished part. We perform all necessary secondary operations, from CNC machining and threading to critical heat treating processes, guaranteeing your components meet exact dimensional and performance requirements.

We guarantee your parts arrive safely and corrosion-free. Every component is treated with anti-corrosion oil, individually wrapped, and secured in foam-lined boxes within sturdy export-grade crates. To simplify your international logistics, we handle the entire export process: from preparing all customs paperwork (CO, Form A/E, etc.) to arranging reliable sea, air, or courier shipping to your destination.

First:How do we define a custom forged metal part?

Unlike cast or machined parts, custom forged components are made by compressing heated metal into the required shape, which refines the grain structure and eliminates weak points. This gives them exceptional durability, load-bearing strength, and resistance to fatigue, making them ideal for demanding industrial applications.

Metal forging is often chosen when parts must be extremely strong, reliable, and able to withstand heavy wear and impact. This process is widely applied in cars, airplanes, energy equipment, industrial machinery, and defense hardware — especially for parts that face constant pressure or harsh working conditions.

Technical Specifications of Custom Molded Components

The forging process enhances metallurgical structure by aligning the grain flow while closing internal voids and porosity. As a result, forged parts exhibit superior mechanical performance, with tensile strength and impact resistance often exceeding cast or machined equivalents by as much as 30%.

We offer forging solutions across multiple materials such as carbon steels, alloy steels, stainless steels, aluminum, titanium, and copper-based alloys. Our capacity covers parts from 0.5 kg to over 100 kg, tailored to design requirements.

Closed-die forging makes it possible to create everything from basic parts to detailed components with features like ribs, bosses, and gears — all with precision and consistency.

Modern forging presses operate with automated feeding, trimming, and transfer systems to support continuous production, ideal for mid to high volume OEM requirements.

Primary Forging Processes

- Open-Die Forging: Injection molding is a high-precision manufacturing method capable of producing complex geometries and holding tight tolerances. It is the optimal process for the high-volume production of thermoplastic components.

- Closed-Die (Impression-Die) Forging: Used for hollow components like bottles and containers, combining efficiency with durability.

- Hot Forging: is an efficient and economical process for shaping plastic sheets into durable trays, protective enclosures, and finished panels.

- Cold Forging: Perfect for bringing complex prototypes and low-volume custom designs to life quickly and without the expense of traditional tooling.

- Upset Forging: Achieve exceptional precision without the cost of tooling. Our machining service is perfect for producing low-volume specialty parts and functional prototypes from durable engineering plastics.

- Precision Forging:Create stronger, smarter components by seamlessly bonding different materials or embedding metal inserts directly into plastic during molding. This eliminates assembly steps and improves product performance.

Practical Applications of Engineered Plastics Across Industries

Forged crankshafts, rods, gears, spindles, and suspension arms engineered for long service life and resistance to heavy stresses.

Forged airframe structures, landing gear assemblies, and engine components designed to deliver both reduced weight and maximum safety.

Forged airframe structures, landing gear assemblies, and engine components designed to deliver both reduced weight and maximum safety.

High-performance engineered polymers for consumer appliances and smart home devices.

Critical components such as axles, wheels, couplings, and propeller shafts built for durability and reliability under fluctuating loads.

Second: Your Guide to Forging Processes and PRIME’s Capabilities

Comprehensive for Guidance

For both newcomers and experienced buyers, this section highlights the fundamentals of forging and PRIME’s role in producing high-quality components. You’ll learn about core processes, major benefits, and how our advanced capabilities solve challenges in strength, precision, and productivity.

Understanding Metal Forging: Built on Strength

Forging is a metal forming technique that shapes material under compressive forces using hydraulic or mechanical presses. By refining the grain structure and removing porosity, the process yields components with superior mechanical performance. It is commonly applied in structural parts, powertrain systems, and heavy-duty industrial applications where safety and reliability are critical. At PRIME, our forging capabilities ensure excellent material flow, optimized strength-to-weight performance, and extended service life for industries such as automotive, aerospace, and energy.

Application-Specific Forging Capabilities

The choice of forging method directly impacts quality, efficiency, and overall cost. PRIME’s experts carefully review your design specifications and performance goals to recommend the best-fit solution. Here are some of the main forging processes we employ.

1. Forging Large Parts with Structural Integrity Through Open Die Processes

In open-die forging, metal is compressed between flat dies, allowing free deformation in several directions. This method is commonly used for large parts like cylinders, blocks, flanges, and shafts, ensuring improved grain alignment and superior strength. PRIME’s advanced CNC-controlled presses guarantee precision, reduced stress concentrations, and repeatable quality.

2.Forming Complex Components with Precision Using Closed Die Forging

Known as impression die forging, this process uses shaped dies to press metal into intricate 3D forms through single or multiple cycles. It is well-suited for higher production volumes, producing near-net shapes with minimal waste and smooth surface finishes. PRIME supports this with custom die manufacturing, automated flash control, and precision trimming, achieving tolerances as fine as ±0.02 mm.

3. Efficient Metal Forming Without Heat: Cold Forging

Accelerate your product development with plastic CNC machining. This process delivers precision-machined parts from high-performance plastics without the delay or expense of tooling. It’s the fastest way to get functional prototypes, specialty components, and complex parts with exacting geometries into your hands.

4. Forging Precision Components with Minimal Machining

By shaping parts near their finished dimensions, precision forging minimizes secondary machining operations. It is particularly suited for demanding applications such as aerospace components, turbine blades, and gear blanks. PRIME leverages state-of-the-art simulation tools and flashless forging technology to achieve accurate, efficient, and repeatable production.

Third: Choosing the Right Materials for Forged Components

Our role goes beyond simple advice. We help you choose materials that align with performance needs, forging capabilities, and industry regulations, minimizing risk and optimizing cost from design to delivery.

How We Help You Choose the Right Forging Material

We ensure your product’s success by expertly matching plastic properties to your needs for function, longevity, and production efficiency.

Material Certification and Tracking Assurance

Each order is backed with complete MTR documentation, including chemical and mechanical test results for every heat. This ensures transparency, traceability, and adherence to the strict standards of industries such as aerospace, automotive, and oil & gas.

Design Support Optimized for Forging

We help you design smarter parts by choosing the right shapes and materials. This makes the metal flow better, cuts down on extra machining, and reduces stress inside the part — giving you stronger, more efficient components with less waste.

Material Certification and Tracking Assurance

PRIME’s cost evaluation methodology extends beyond unit weight, incorporating variables such as forging cycle efficiency, thermal and energy inputs, secondary processing demands, and in-service wear. This holistic approach enables informed procurement decisions with improved lifecycle economics.

The Alloy Raw Material Preparation

All those above noted raw material forged and change into wire state prepared for manufacturing this way can save for alloy steel, aluminum, carbon steel,stainless steel, zinc alloy,copper and brass

Fourth: Surface Finishing & Coatings for Forgings

To maximize durability and functionality, forged parts require proper surface finishing. PRIME offers a range of industrial-grade treatments that strengthen resistance to wear and corrosion, improve aesthetics, and ensure compliance with technical regulations.

Hot-Dip Galvanizing: A thick zinc coating for outdoor and structural forged parts, giving long-lasting rust protection.

Black Oxide & Phosphate: Common finishes in cars and tools that make parts harder and more resistant to corrosion.

Powder Coating: A tough, UV-safe coating that works great on brackets, frames, and housings.

Blasting (Shot & Sand): Cleans the surface and makes it easier for coatings or paints to stick.

Pickling & Passivation: Special treatments that keep stainless steel parts rust-free, often used in food and hygiene industries.

Deburring & Polishing: Smooths rough edges and gives forged parts a clean, polished look.

Fifth: Durable Forging Dies and Precision Tooling

We design and verify your molds and fixtures for absolute stability and accuracy, ensuring every one of your parts meets the highest standards of precision, time after time.

Smart Die Design: Computer simulations predict how metal flows and where stress builds before we even cut the die.

Trial Tooling: Quick, lower-cost trial dies test complex shapes before full production.

Precision Machining: Dies cut with CNC and EDM for accuracy within ±0.01 mm, using tough tool steels.

Stronger Dies: Special coatings and heat treatments make tooling last longer and resist wear.

Real-World Testing: Full forging trials plus detailed inspections ensure the tooling and finished parts meet quality standards.

Sixth:Typical Forging Issues and Our Prevention Approach

Quality at PRIME isn’t a final check—it’s part of the entire process. We control every stage, from raw material verification to packaging, with rigorous testing and data-driven oversight to ensure global compliance.

1.Raw Material Inspection: Heat number tracking combined with material test report reviews confirms compliance with required chemical and mechanical standards before manufacturing begins.

2.Real-Time SPC Monitoring: Real-time data acquisition supported by control charts, with automatic alarms triggered for variations in critical factors such as press force or cycle time.

3.Dimensional Inspection: 100% sampling with GO/NO-GO gauges and precision measurement tools.

4.End-of-Line CMM Inspection:Integrated camera systems provide continuous monitoring, detecting burrs and blemishes as parts are produced

5.Product Compliance Certificate: A full Certificate of Conformance is provided with every batch, verifying compliance across materials, processes, and inspections.

Casting Parts Quality Inspection Process

1.Raw Material Verification

Material Certificates Review: Check Mill Test Reports (MTRs) for chemical composition and mechanical properties.

Traceability Check: Confirm heat numbers and batch tags are consistent with documentation.

Non-Destructive Testing (NDT): Perform ultrasonic or magnetic particle inspection on billets to ensure internal integrity.

2.Pre-Forging Preparation Inspection

Billet Dimensions: Verify diameter, length, and weight match process requirements.

Surface Condition: Check billets for cracks, rust, or contamination.

Heating Control: Ensure furnace calibration, correct heating curves, and uniform billet temperature before forging.

3. In-Process Forging Monitoring

Die Condition Check: Inspect forging dies for wear, cracks, or misalignment before and during production.

Process Parameters: Monitor forging temperature, press tonnage, stroke cycles, and deformation rates.

Grain Flow Observation: Confirm flow lines follow part geometry through sectioning or simulation validation.

4. Dimensional Inspection

First Article Inspection (FAI): Measure initial forged parts against CAD/2D drawings.

CMM & 3D Scanning: Use coordinate measuring machines and scanning technology to ensure tolerance accuracy.

Go/No-Go Gauges: Apply gauges for critical fits and features.

5. Mechanical & Metallurgical Testing

Die Condition Check: Inspect forging dies for wear, cracks, or misalignment before and during production.

Process Parameters: Monitor forging temperature, press tonnage, stroke cycles, and deformation rates.

Grain Flow Observation: Confirm flow lines follow part geometry through sectioning or simulation validation.

6. Surface Quality Inspection

First Article Inspection (FAI): Measure initial forged parts against CAD/2D drawings.

CMM & 3D Scanning: Use coordinate measuring machines and scanning technology to ensure tolerance accuracy.

Go/No-Go Gauges: Apply gauges for critical fits and features.

7. Non-Destructive Final Testing

Die Condition Check: Inspect forging dies for wear, cracks, or misalignment before and during production.

Process Parameters: Monitor forging temperature, press tonnage, stroke cycles, and deformation rates.

Grain Flow Observation: Confirm flow lines follow part geometry through sectioning or simulation validation.

8. Documentation & Certification

First Article Inspection (FAI): Measure initial forged parts against CAD/2D drawings.

CMM & 3D Scanning: Use coordinate measuring machines and scanning technology to ensure tolerance accuracy.

Go/No-Go Gauges: Apply gauges for critical fits and features.

Seventh:Typical Casting Defects and PRIME’s Preventive Measures

Custom metal forging requires exact control of temperature, pressure, and material flow. Even small deviations may lead to defects affecting structural strength. At PRIME, we prevent these risks with optimized die design, rigorous process monitoring, and thorough inspection practices.

1. Laps & Cold Shuts

Surface cracks or overlapping folds form when material flow is restricted or forging temperature is too low.

PRIME Solution: Through optimized preform geometry, strict die heating control, and continuous thermal monitoring, we secure smooth metal flow and eliminate laps.

2. Incomplete Die Fill

Description: Parts may be undersized or missing features due to insufficient material volume or forging pressure.

PRIME Solution: Using advanced simulations, calibrated preforms, and progressive die systems, PRIME guarantees complete die cavity filling with repeatable accuracy.

3.Scale Pitting & Surface Oxidation

Description: Oxidation during heating produces surface scale, leaving pits or rough textures on forgings.

PRIME Solution: Controlled furnace environments, protective anti-scale coatings, and corrective pickling treatments protect surface integrity.

4. Internal Cracks

Description:When slag, oxides, or other non-metallic contaminants mix into molten metal, they may solidify within the casting, creating inclusions that weaken the structure and degrade performance.

PRIME Solution: Through high-efficiency melting technology and ceramic filter systems, we maintain clean molten metal and precisely control pouring conditions to eliminate slag inclusions.

5. Dimensional Deviations

Description: Parts come out slightly off-size due to die wear or heat effects.

PRIME Solution:High-precision CNC dies, protective coatings, and final 3D scans ensure every part meets exact specs.

Eighth:A Guide to Choosing a Reliable Forged Parts Supplier

A dependable forging supplier is vital for achieving mechanical integrity, dimensional accuracy, and economic value. In addition to price and materials, assess their quality systems, engineering knowledge, and production scalability. The following guide highlights what to look for in a high-quality forging partner.

1.ISO & Industry Compliance Assurance

2.Material Knowledge & Forging Capabilities

- Premium castings must satisfy strict standards for dimensional accuracy, mechanical performance, and surface finish. It is essential to confirm that your supplier operates under a certified quality system (e.g., ISO 9001, IATF 16949) and is equipped with advanced inspection tools such as CMMs and spectrometers.

- Each casting method (sand casting, gravity casting, die casting, etc.) has unique process requirements. A reliable supplier should offer multiple process options and advanced equipment to support both custom projects and large-scale production.

3.Forging Accuracy and Quality Assurance

4.Engineering Integration with DFM

- Since material properties vary by application, it is crucial to assess whether a supplier can provide professional advice on material choice, customized alloy solutions, and detailed performance analysis as a measure of their competence.

- Delayed deliveries may disrupt project timelines or result in missed sales opportunities. A supplier’s ability to maintain stable production scheduling, effective inventory management, and reliable logistics is directly tied to supply chain security.

5.Price Competitiveness and Value Delivery

6.Client Case Studies and Market Reputation

- We combine price competitiveness with strong value delivery, offering cost-effective solutions without compromising on product quality, lead time, or service excellence. Our approach ensures customers receive the best balance between affordability and long-term performance.

- Our client case studies highlight successful projects across diverse industries, while our solid market reputation reflects decades of reliable service, quality products, and lasting partnerships worldwide.

For companies interested in establishing lasting foundry partnerships, we provide free technical guidance and sample evaluations — contact us today.

Ninth:Design for Forging Manufacturability (DFM)

Maximize strength, performance, and cost-effectiveness in your forged components with our DFM expertise.

Buyer’s hesitation: “Given the complex geometry of my part, I’m worried about several issues—will the material flow as needed during the forging process, how much will the tooling cost, and could there be internal defects or weaknesses in the material? What steps can I take to ensure that forging is the right method for this part and that these challenges are minimized?”

PRIME’s DFM service incorporates detailed forging-specific design evaluations, aimed at cutting down machining requirements, limiting material waste, and preventing premature die wear or failure.

1.Front-End Engineering & CAD Evaluation

By reviewing both 3D models and 2D drawings, we assess overall geometry, material volume, and production feasibility. We advise on design adjustments to ensure smooth grain flow and reduce tooling complexity.

2.Resource & Cost-Effective Forging

Feature Redesign: Modifying challenging geometries to improve tooling feasibility.

Tool Life Improvement: Design solutions aimed at prolonging die service life and reducing downtime.

Minimizing Post-Processing: Utilizing progressive dies to reduce reliance on secondary operations such as welding or trimming.

3.Smarter Material Use, Lower Production Costs

- Geometry Redesign: Modification of difficult part features to optimize metal flow and ensure die fill.

- Tooling Durability Enhancement: Engineering solutions targeted at extending die life and minimizing press downtime.

- Secondary Operation Reduction: Application of progressive die sequences to decrease dependency on post-forging welding, trimming, or machining.

4. Precision Dimensional Control & Defect Management

Accurate Dimensions That Work: Parts fit right and stay safe in use.

Smart Digital Correction: Computer models fix forming errors before they happen.

No Defects, No Worries: Preventing wrinkles, cracks, and rough edges from the start.

Tenth:Selecting Between Custom Forging and CNC Machining for Metal Parts

B2B buyers frequently wonder whether it’s better to choose forging or CNC machining for their specific needs, weighing the pros and cons of each method to find the most efficient solution for their parts.

Each of these manufacturing techniques—forging and CNC machining—brings unique benefits, from enhanced mechanical strength to cost-effectiveness and design adaptability. At PRIME, we are equipped to offer both precision forging and CNC machining, ensuring we can tailor our recommendation to your part’s specific geometry, material choice, and performance demands.

Forging Solutions Tailored for Load-Bearing Strength, Wear Resistance, and Production Efficiency

Mechanical Strength: Controlled grain flow follows part geometry, delivering maximum durability.

Material Efficiency: Near-net shape forging reduces machining time and minimizes material waste.

Volume Production: Well-suited for consistent mid- to high-volume runs with extended die service life.

Size & Weight Flexibility: Capable of producing medium to very large structural components.

Impact Resistance: Forged parts provide superior performance under high-stress conditions compared to machined components.

By removing material from solid blanks, CNC machining creates detailed and exact parts. This process offers outstanding flexibility and precision across a wide range of shapes.

Ultra-High Accuracy: Achieves tolerances and 3D details beyond the limits of casting.

Broad Material Capability: Handles metals, plastics, and composites without casting restrictions.

Flexible for Short Batches: Eliminates tooling costs for economical low-quantity runs.

Easily Adjustable: Design changes implemented via software, not hardware.

Minimal Secondary Work: Parts emerge with smooth, precision finishes.

Eleventh:Global Distribution Networks & Supply Chain Solutions

In global sourcing, reliable delivery is as critical as the forgings themselves. PRIME leverages years of trade expertise and a proven logistics infrastructure to ensure secure, timely, and economical shipment of your components anywhere in the world.

Buyer’s worry: “I’m ordering precision forged components from abroad, and I want to know how I can ensure that customs clearance is efficient, delivery timelines are reliable, and there are no surprise charges or hidden fees during the shipping and import process.”

Procurement question: “As we import precision forged parts internationally, what safeguards ensure accurate classification and smooth customs processing, stable ETD/ETA performance, and a clear landed-cost breakdown without hidden charges?”

1.Trade Compliance & Export Expertise

- CNC Machining: Delivers extreme accuracy in threads, bores, and multi-axis profiles where casting falls short.

- Tapping & Reaming: Ensuring dimensional accuracy and functional fits in threaded and reamed holes.

- Grinding: Precision control of thickness, flatness, and smoothness for critical surfaces.

2. Flexible Transport Strategies

- Mechanical Assembly: Seamlessly joining castings with springs, screws, and molded elements.

- Welding: Reliable metal joining through MIG, TIG, and spot processes.

- Fastener Insertion: Embedding threaded elements and studs by hand or automation.

3. Real-Time Tracking & Proactive Communication

- Kitting: Customized part kits prepared for efficient line-side assembly.

- Custom Packaging: Designed to reduce damage risks and optimize freight space.

- Labeling & Barcoding: Clear identification and inventory integration through custom labeling systems.

4.Secure Packaging & Damage Control

- Annealing: Reduces residual stresses and improves ductility prior to machining or forming.

- Annealing: Conditioning step that enhances durability and processability.

The PRIME Complete Manufacturing Edge

Concentrate on your forging needs — PRIME takes care of logistics. We ensure your forged components are shipped worldwide with efficiency, safety, and reliability.

PRIME’s Edge in Precision Logistics

Twelfth:PRIME Research & Development — Driving Progress in Metal Casting

Procurement question: Can this supplier collaborate early on design, run simulations and pilot trials, and scale production while adapting to new technical constraints and changing industry requirements?

Custom forging rewards innovators. At Prime, sustained R&D lets us explore new geometries, refine grain flow, and optimize heat-treat windows and die life. The result: high-strength, high-reliability forged components that meet evolving specs and endure in real-world use.

1.Advanced Material & Engineered Alloys

We engineer carbon steel, stainless, aluminum, brass, and nickel alloy fasteners—precision-tuned for strength, corrosion resistance, or weight savings in critical applications.

2. Process Optimization & Automation

Our research team pioneers eco-friendly production through:

Energy Efficiency: Lower your Scope 3 emissions with our energy-efficient forming

Waste Reduction: Chip-free manufacturing maximizes material value

3. Sustainable Manufacturing

Co-developed solutions for unique challenges: anti-loosening threads, dielectric barriers, integrated washers, and precision torque features – scaled from concept to volume production.

4. Tailored Casting Solutions

We collaborate closely with clients to develop non-standard fasteners — including anti-vibration features, insulation barriers, captive washers, and torque-control geometries — from prototype to production.

PRIME’s Fastener Innovation Edge:

Prime transforms fastener potential through advanced materials, smart manufacturing, and collaborative engineering – delivering tomorrow’s solutions today.

Thirteenth:From Casting to Completion — Value-Added Services That Deliver More

Reducing vendor numbers and simplifying supply chains helps B2B buyers cut costs, boost efficiency, and eliminate unnecessary complexity. PRIME delivers a full spectrum of value-added services, providing one-stop solutions that take castings from raw form to ready-to-use parts—saving you time and management effort.

Procurement lens: “We’re seeking a single supplier that can forge, finish to tight tolerances, handle assembly/kitting, and ship in line-ready, labeled packaging—eliminating the need to manage several vendors.”

PRIME’s vertically integrated model—own operations plus vetted partners—covers the full forging lifecycle, minimizing touchpoints, accelerating schedules, and ensuring tight process control from raw stock to delivery.

1. Supplementary Machining Processes

- CNC Machining: For ultra-tight tolerances, threads, complex bores, and 3D profiles that casting alone can’t achieve.

Tapping & Reaming: Fine-tunes hole dimensions and creates reliable threaded connections.

Grinding: For smooth surfaces, dimensional accuracy, and consistent flatness.

2. Component Assembly & Module Subassembly

Mechanical Assembly: Joining castings with hardware, inserts, and complementary components.

Mechanical Assembly: Integrating castings with all secondary components under one roof.

Mechanical Assembly: From Casting to Full Assembly.

3.Assembly Kitting & Protective Packaging

- Kitting: Consolidating parts into pre-packaged sets for faster, easier assembly.

Custom Packaging: Designed for safe transport and optimal use of cargo space.

Labeling & Barcoding: Barcode-enabled identification for simplified logistics and supply chain flow.

4.Heat Treatment

Annealing: Improves flexibility and reduces brittleness to prepare parts for shaping or machining.

Hardening & Tempering: Ensures long-lasting strength and performance in functional parts.

5. Cleaning and Edge Refinement

Precision Cleaning: Cleans parts thoroughly for smooth machining, coating, or assembly.

Advanced Deburring: Precision removal of burrs via automated polishing and laser finishing.

Fourteenth:Processing technology

Rolling forging

Features

- Rolling forging uses specialized rotary tools to gradually shape heated metal billets into precise, durable components

- Improves metal microstructure and mechanical properties for superior performance

Applications

- Manufacturing of automotive shafts, gears, and transmission parts requiring long service life

- Production of aerospace components where strength-to-weight ratio is critical

Open die forging

Features

- Open die forging shapes heated metal billets using flat or simple dies

- Lower tooling cost compared to closed die forging, making it economical for small-batch production

- Allows flexibility in producing a wide range of sizes

Applications

- Large-size forgings for construction machinery, such as beams and support frames

- Heavy-duty mining equipment parts like shafts, rollers, and crusher components

Closed die forging

Features

- Closed-die forging places heated metal blanks into precision dies, with hydraulic or mechanical presses filling the entire cavity

- Produces parts with exceptional dimensional accuracy, consistency, and intricate shapes

- Optimized for high-volume production of precision-engineered components

Applications

- Manufacturing of automotive gears, crankshafts, and connecting rods

- High-strength aerospace components requiring strict tolerances

- Parts for railway systems, petrochemical plants, and heavy machinery

Superplastic forging

Features

- Utilizes the superplastic properties of metals at specific temperatures and strain rates to enable precise forming

- Capable of producing extremely complex and high-precision shapes

- Results in a more uniform and refined internal structure for improved performance

Applications

- Primarily used in the aerospace industry for advanced engineering components

- Ideal for manufacturing complex, high-specification parts such as aero-engine components and turbine blades

Fifteen:Workflow Overview

To guarantee that every metal fastener meets precise customer specifications, we follow a rigorous nine-step quality assurance process, spanning from initial technical review to post-delivery validation

Procedure 1: Choosing the Right Metal Alloy

Before production begins, our engineering team collaborates closely with customers to ensure every part is designed to meet their exact requirements. Using advanced CAD software, we create precise 3D models and conduct thorough analysis and optimization to guarantee functionality and manufacturability.

Procedure 2:Quench & Tempering

We offer a wide selection of metal materials, including aluminum alloys, stainless steel, copper, and more. Based on the specific requirements of each part, we select the most suitable material to ensure optimal performance, strength, and long-term durability.

Procedure 3: Forging

After selecting the appropriate material, we develop a detailed CNC machining program. With computer numerical control technology, we precisely control the cutting path and depth of each tool to ensure the dimensional accuracy and consistency of every part.

Procedure 4:Cooling

Our CNC machine tools execute automated precision machining based on digital programming instructions, performing exact cutting and shaping operations to form complete components. This computer-controlled process ensures consistent dimensional accuracy and detail reproduction without manual intervention, guaranteeing part-to-part uniformity.

Procedure 5:Precision Finishing

All machined parts undergo stringent quality inspections using precision measuring equipment to thoroughly verify dimensions, tolerances, and surface finishes, ensuring complete compliance with design specifications.

Procedure 6:Machining

To meet specific application needs, we offer comprehensive post-processing options including mechanical polishing, powder coating, anodization, and other specialized surface treatments. These finishing processes simultaneously enhance both aesthetic qualities and functional performance – significantly improving corrosion protection and wear characteristics while achieving the desired visual appearance.

Procedure 7: Surface treatment

After completing all inspections and post-processing, the castings are finished and ready for delivery to customers or assembly into final products.

Procedure 8: Comprehensive Quality Verification

Refers to a complete inspection and testing process carried out at every stage of production. It ensures that materials, dimensions, strength, and surface finishes all meet strict standards before parts are approved for delivery. This approach guarantees consistency, reliability, and customer satisfaction.

Procedure 9: Packaging

Upon successful quality verification, all CNC-machined components undergo protective packaging using industrial-grade materials tailored to part specifications and shipping requirements

Procedure 10: Expressing of completed goods

This phrase can refer to the final stage after production, where finished products are either presented, inspected, packaged, or delivered to the customer.

Sixteenth:What Our Clients Said

Maximilian

Product Manager, PM

“Die Zusammenarbeit mit Prime hat unseren Fertigungsprozess erheblich rationalisiert. Ihre Präzision und schnellen Durchlaufzeiten waren ein Schlüsselfaktor für unseren Produktionserfolg.”

Kenta Sato

Purchasing manager,UACJ

“プライムとの協力により、製造工程が大幅に合理化されました。彼らの精度と迅速な納期は、私たちの生産成功の重要な要因となっています”

Elias Söderberg

Production Supervisor,Sandvik AB

“Att arbeta med Prime har avsevärt effektiviserat vår tillverkningsprocess. Deras precision och snabba handläggningstider har varit en nyckelfaktor för vår produktionsframgång.”

Seventeenth:Manufacturing & Packing at A Glance

Eighteenth:In Summary

Supplier selection in casting goes well beyond quoting the lowest price. This guide has highlighted the essentials—process knowledge, material expertise, quality assurance, and global supply reliability. True advantage comes from working with a partner who safeguards today’s performance while fueling tomorrow’s innovation.

Essential Insights for B2B Buyers

- Technical Excellence is Essential: Precision Through Expertise: Today’s castings demand skilled process control and the capability to handle everything from simple parts to intricate geometries.

- Quality Cannot Be Compromised: Zero-Defect Focus: Robust quality control and complete traceability protect your supply chain from costly rework or downtime.

- Think in Terms of Total Cost: Beyond Unit Price: A slightly higher part price may reduce overall expenses by minimizing risk and improving manufacturability.

Worldwide Reach, Local Expertise

With carefully designed export packaging, accurate documentation, and proactive customer service, we make international shipping seamless and reliable.

Whether you need a small order or global supply coverage, PRIME provides tailored fastener solutions with the scalability to match your growth.

Receive a competitive quote within 24 hours

With Prime, you’ll receive a competitive quote within 24 hours — helping you save valuable time in sourcing decisions. Rapid response means you can compare costs, plan budgets, and accelerate your project schedule with confidence.

Simply Customize Metals

Finding top-quality custom metal parts doesn’t have to be complicated. At Prime, we guide you through it in three easy steps:

Three Decades of Trusted Production Experience, Delivered from Our Own Facilities

Custom-Designed Components Engineered for Your Specific Applications

Worldwide Delivery Network with End-to-End Logistics Services

Fast and Transparent Quotes with No Hidden Conditions

Your Designs and Information Stay Fully Confidential — Guaranteed

After you confirm the design and pricing, we’ll start production and manage the shipping—making sure everything arrives on time.

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.