Product

Dedicated to delivering high-quality custom metal fabrication

Provide revolutionary custom metal parts for your industry

Metal components are indispensable in modern industry, particularly in sectors demanding exceptional strength, durability, and precision—such as automotive, electronics, and mechanical manufacturing. At Prime, we specialize in delivering a comprehensive range of high-quality metal products, including precision stampings, CNC-machined parts, industrial castings, fasteners, and engineered plastic components. Every product meets stringent international quality standards, ensuring reliable performance for global customers.

Custom Metal Innovation – Powering the Next Industrial Leap

This Is How We Stand Out

We provide an extensive selection of precision-crafted metal parts tailored to your specifications and budget.

Heavy-Duty Manufacturing Facility

From specialized parts to complete intelligent production solutions – our well-stocked facility and experienced team stand ready to fulfill your manufacturing needs.

Advanced Manufacturing Capabilities

With multiple dedicated production lines and advanced equipment, we deliver maximum throughput efficiency to consistently meet your volume and quality requirements

Affordable Excellence experience

Customized production processes that ensure premium quality while maximizing your cost savings through our competitive pricing structure

Integrated Technical Support

We offer end-to-end tailored solutions—from pre-sales consulting and bespoke manufacturing to after-sales service—all aligned with your product needs.

Section 1

Quality Management

Quality Management refers to the systematic process of ensuring that products, services, and processes consistently meet or exceed customer expectations and industry standards. It involves planning, controlling, and improving quality at every stage of production or service delivery.

Section 2

Supply Chain & Manufacturing Strength

Supply Chain & Manufacturing Strength refers to an organization’s ability to efficiently produce and deliver high-quality products while maintaining a resilient, cost-effective, and agile supply chain. It encompasses robust manufacturing capabilities, such as advanced production technologies, skilled workforce, lean processes, and consistent quality control, ensuring products meet demand with precision and reliability.

Section 3

High Temperature and Pressure Resistance

High Temperature and Pressure Resistance refers to the ability of a material, component, or system to maintain its structural integrity, functionality, and performance under extreme heat and intense pressure without degrading or failing.

Section 4

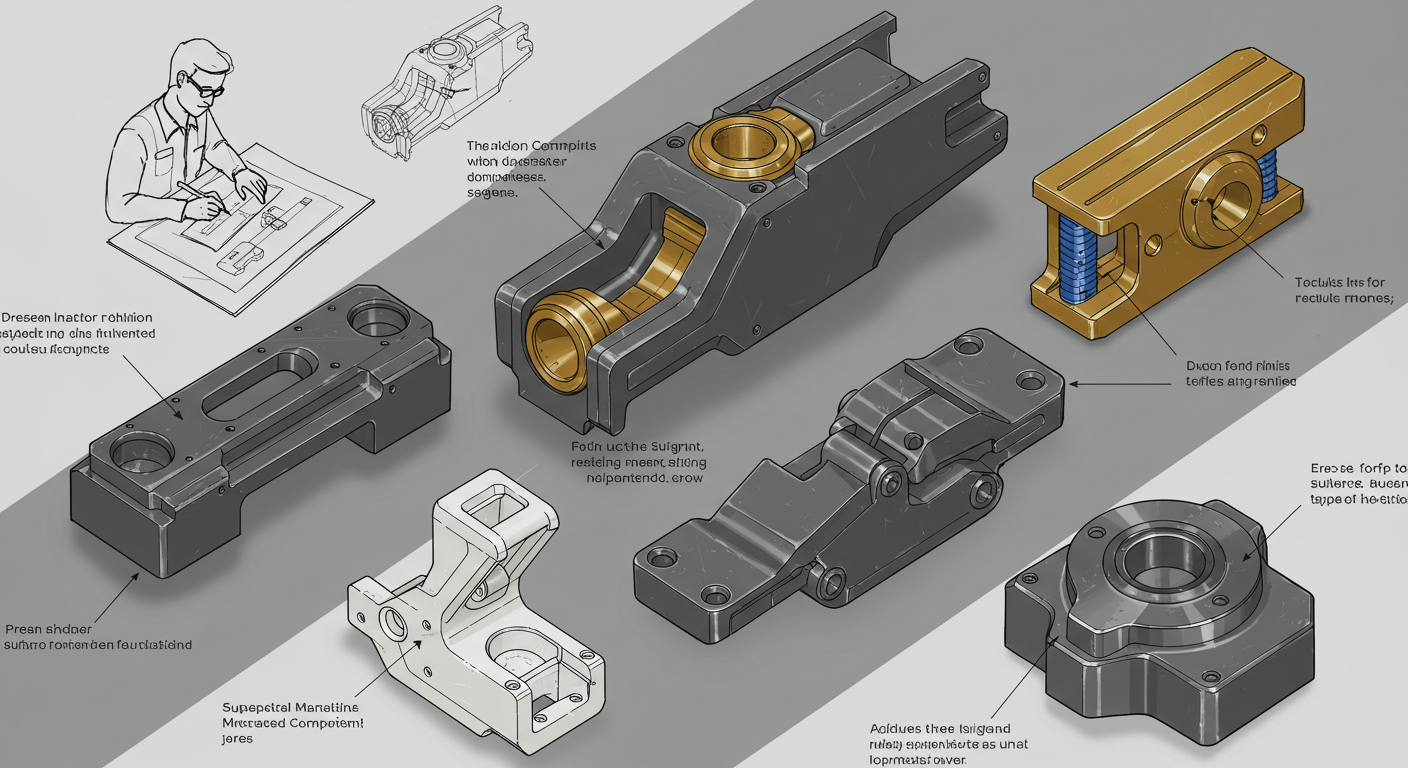

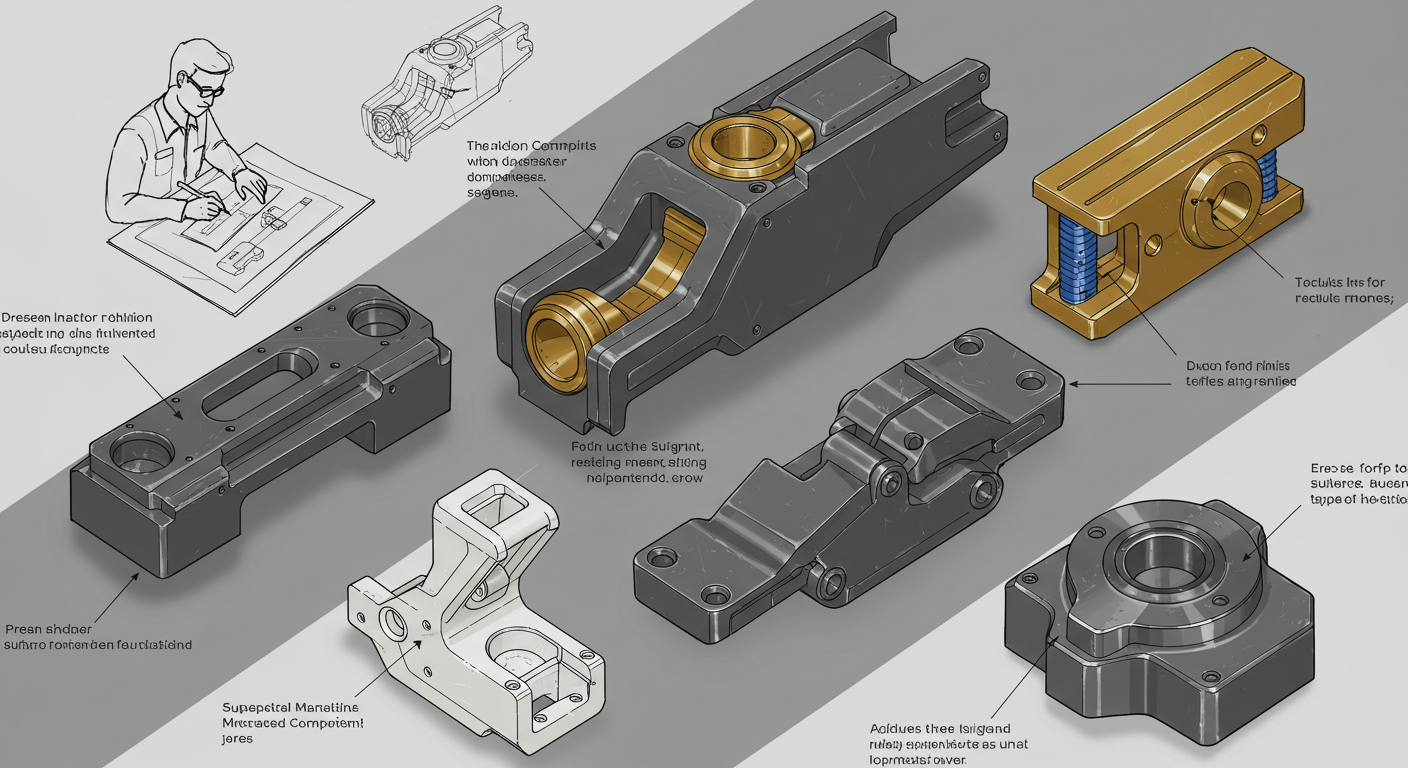

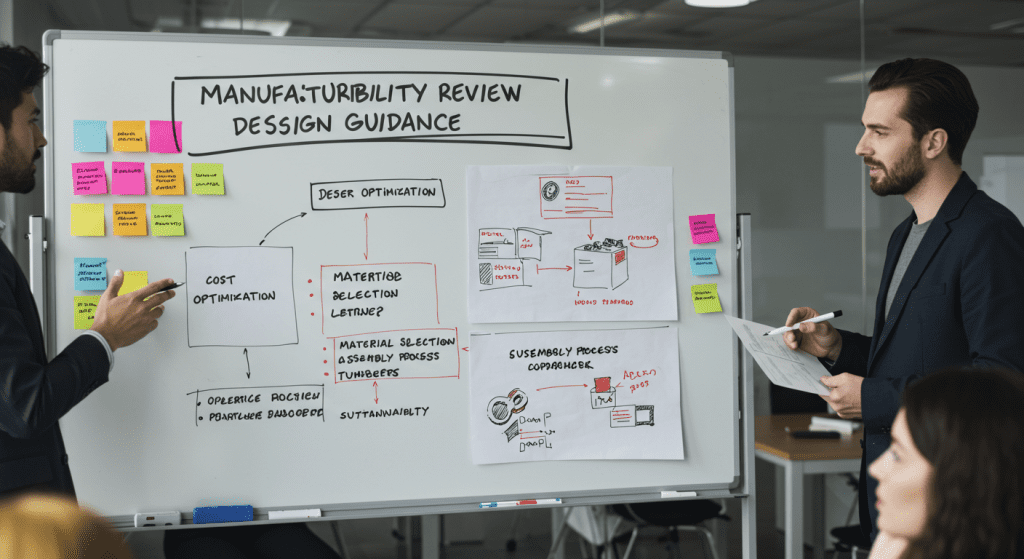

Best Practices for Designing Metallic Components

Supply Chain & Manufacturing Strength refers to an organization’s ability to efficiently produce and deliver high-quality products while maintaining a resilient, cost-effective, and agile supply chain.

Section 5

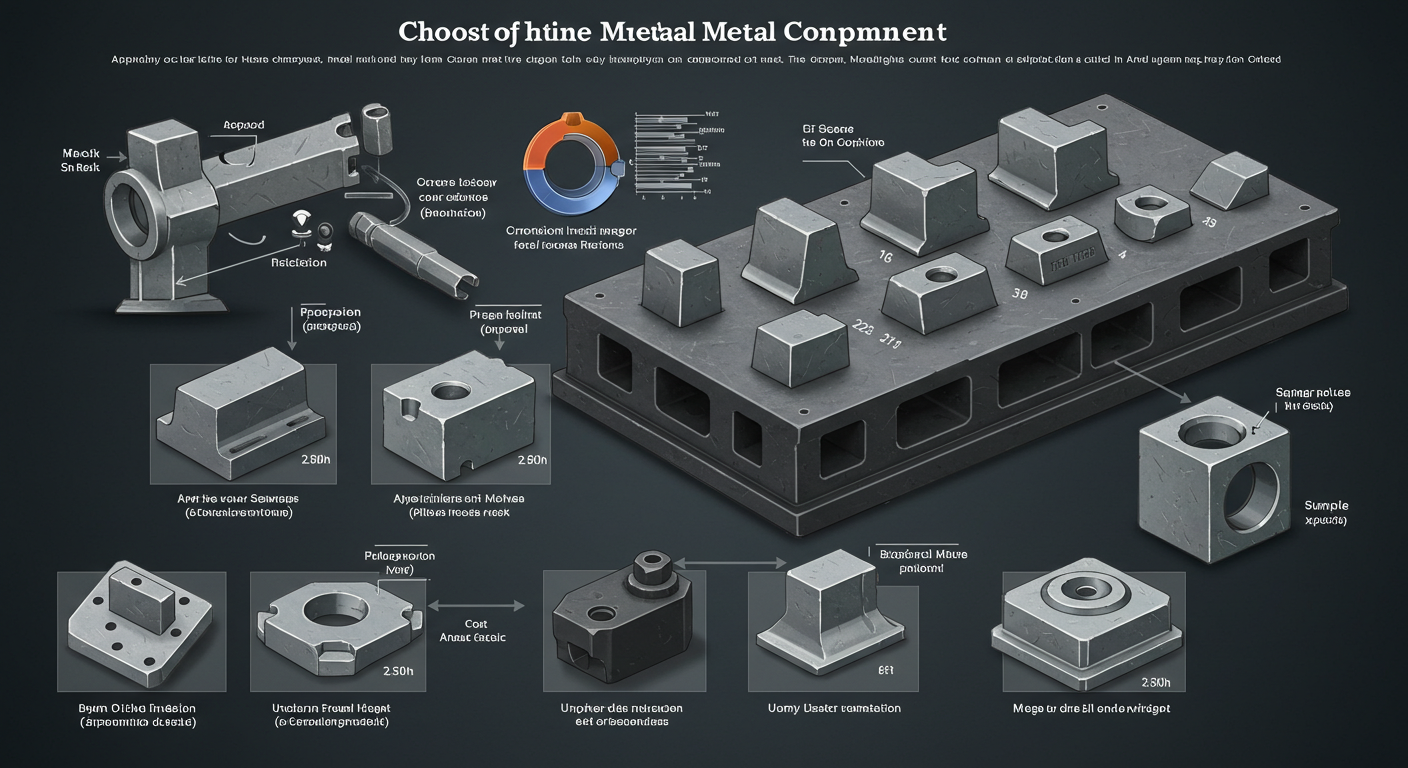

Selecting the Ideal Metal Component for Your Application

Selecting the Ideal Metal Component for Your Application involves a careful evaluation of material properties, operational demands, and economic factors to ensure optimal performance and longevity.

Section 6

Smart Budgeting for Custom Metal Parts

Smart Budgeting for Custom Metal Parts refers to the strategic approach of optimizing costs while maintaining quality, functionality, and lead times in the production of tailor-made metal components. This involves careful material selection—balancing performance needs with affordability—such as choosing carbon steel over stainless steel when corrosion resistance isn’t critical.

Section 7

Guiding You Every Step of the Way

Pre-Design and Engineering Planning

Our systematic approach ensures seamless production, adhering strictly to your defined methods and tolerances.

Precision Production Planning:

We establish a detailed manufacturing sequence, ensuring accuracy and consistency at every stage.

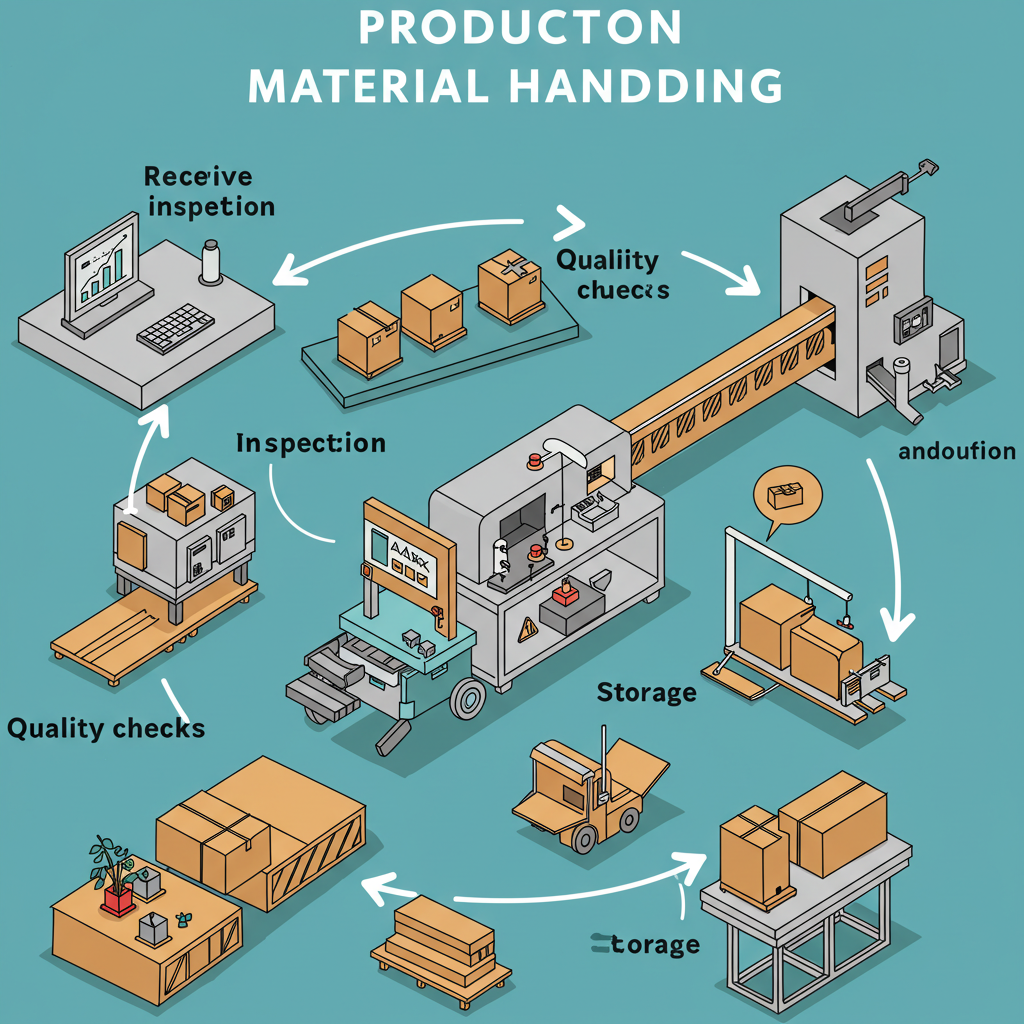

Pre-Production Material Handling

Precisely specifying metal materials (e.g., steel grades) based on product performance requirements.

Stock Sizing

Precision sizing of material stock for downstream operations

Incoming Material Verification

Thorough inspection of raw materials prior to production use

Processing Technology

Shipping Arrangement – Planning and executing the method of delivery (maritime, air freight, trucking, etc.).

Distribution – Delivering the finished product to the end user with required certifications.

Mapping with Step One by One

Collaborating with process engineers to verify design compatibility with machining capabilities

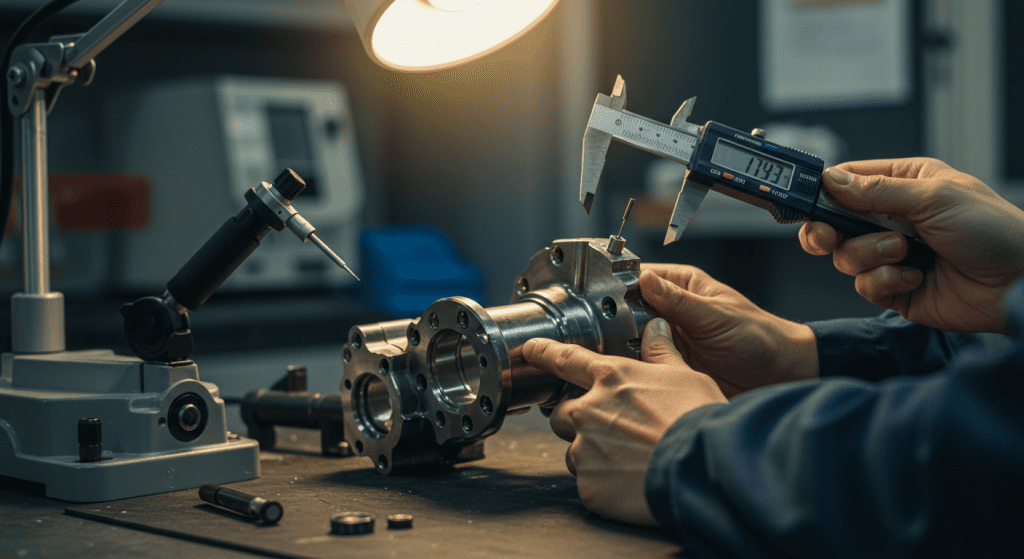

CNC Machining Standards Clarification

Formally communicating critical tolerances (±0.XXmm) and surface finish requirements (Ra X.XXμm) to ensure part compliance.

Process Traceability Review

Auditing CNC process parameters (feeds/speeds, coolant logs) against stamping defect patterns (cracks, dimensional drift).

Value-Added Finishing

Precision removal of stamping burrs to achieve uniform edge profiles

Closed-Die Compression

Forging process that achieves net-shape tolerances through extreme pressure

Assembly Welding

Permanently integrating components through welded joints

Surface treatment

Precisely coating parts via controlled electrochemical metal deposition

Liquid Coating

Spraying paint or resin-based finishes for uniform coverage.

Precision Polishing

Achieving micron-level smoothness for critical applications (e.g., optics, medical devices).

Process Performance Qualification

Shipping Arrangement – Planning and executing the method of delivery (maritime, air freight, trucking, etc.).

Distribution – Delivering the finished product to the end user with required certifications.

Precision Alignment Processes

Purification – Eliminating unwanted substances (oil, dirt, etc.) from the part's surface.

Transportation - Ready Packaging

Ensuring containers withstand shocks, vibrations, and environmental factors during shipping.

Cross-Docking Operations

Shipping Arrangement – Planning and executing the method of delivery (maritime, air freight, trucking, etc.).

Distribution – Delivering the finished product to the end user with required certifications.

In-Summary

Summaries save time by distilling complex content into digestible takeaways. In business, an executive summary outlines critical insights; in casual settings, TL;DR (Too Long; Didn’t Read) offers a snapshot.

Section 8

Key Reasons to ChooseComponents for Industrial Use

Key Reasons to Choose [Company Name] Components for Industrial Use highlights the critical advantages that make [Company Name] the preferred supplier for high-performance industrial components. Our products are engineered for durability, precision, and reliability—using premium materials like high-grade alloys and advanced composites to withstand extreme temperatures, pressure, and wear.

Section 9

The Long-Term Value of Reliable Metal Components

The Long-Term Value of Reliable Metal Components lies in their ability to deliver consistent performance, reduce operational costs, and minimize downtime over their entire lifecycle. High-quality metal parts—crafted from durable materials like stainless steel, titanium, or specialized alloys—resist wear, corrosion, and extreme conditions, ensuring longevity even in demanding industrial environments.

Section 10

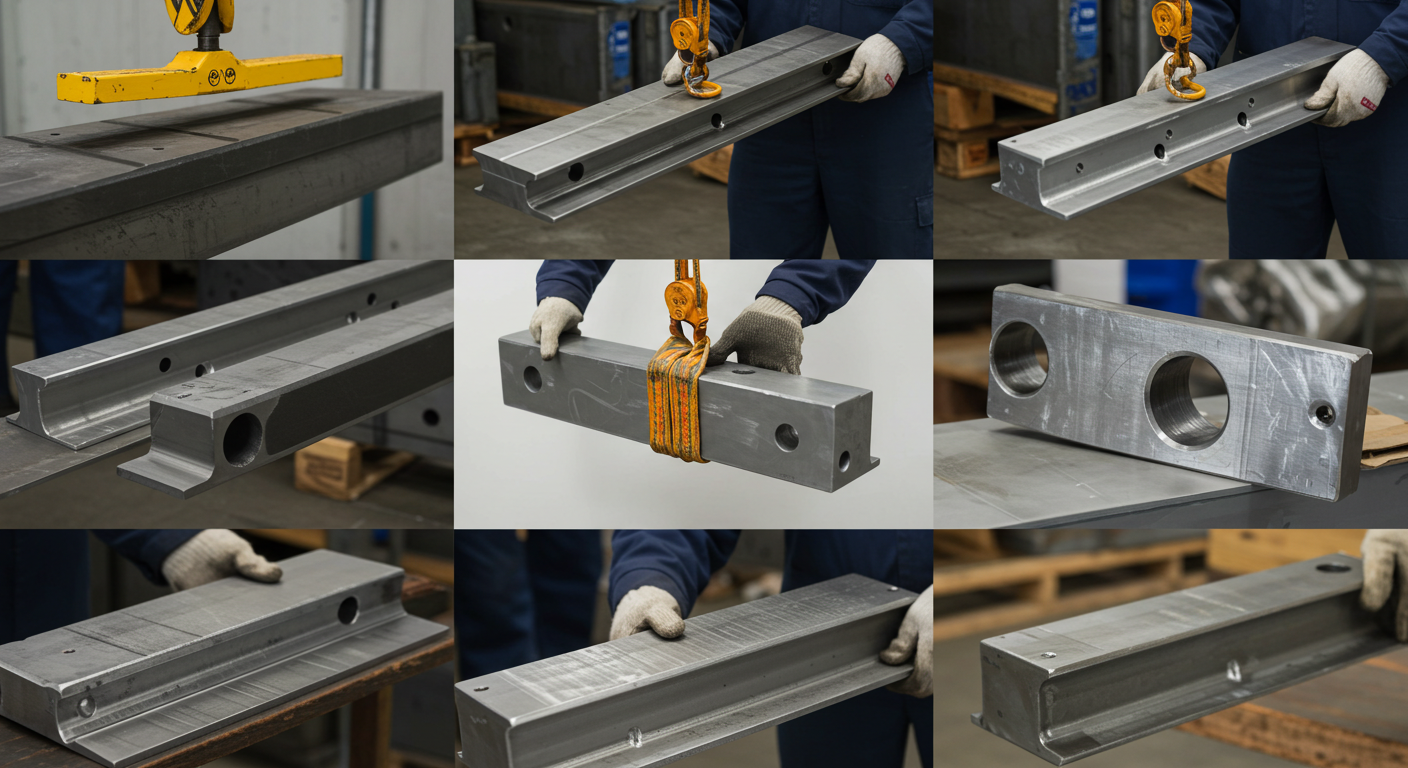

Safe Handling Procedures for Industrial Metal Components

Safe Handling Procedures for Industrial Metal Components refer to the standardized protocols and best practices designed to protect workers, equipment, and the integrity of metal parts during transportation, installation, maintenance, and storage. labeling and storage conditions (e.g., dry, climate-controlled spaces) prevent material degradation.

Maximilian

Product Manager, PM

“Die Zusammenarbeit mit Prime hat unseren Fertigungsprozess erheblich rationalisiert. Ihre Präzision und schnellen Durchlaufzeiten waren ein Schlüsselfaktor für unseren Produktionserfolg.”

Kenta Sato

Purchasing manager,UACJ

“プライムとの協力により、製造工程が大幅に合理化されました。彼らの精度と迅速な納期は、私たちの生産成功の重要な要因となっています”

Elias Söderberg

Production Supervisor,Sandvik AB

“Att arbeta med Prime har avsevärt effektiviserat vår tillverkningsprocess. Deras precision och snabba handläggningstider har varit en nyckelfaktor för vår produktionsframgång.”

Receive a competitive quote within 24 hours

With Prime, you’ll receive a competitive quote within 24 hours — helping you save valuable time in sourcing decisions. Rapid response means you can compare costs, plan budgets, and accelerate your project schedule with confidence.

Simply Customize Metals

Finding top-quality custom metal parts doesn’t have to be complicated. At Prime, we guide you through it in three easy steps:

Three Decades of Trusted Production Experience, Delivered from Our Own Facilities

Custom-Designed Components Engineered for Your Specific Applications

Worldwide Delivery Network with End-to-End Logistics Services

Fast and Transparent Quotes with No Hidden Conditions

Your Designs and Information Stay Fully Confidential — Guaranteed

After you confirm the design and pricing, we’ll start production and manage the shipping—making sure everything arrives on time.

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.