What’s the minimum and maximum thickness Prime can handle for custom stamped components?

Are you designing a new product and unsure if your sheet metal part is too thin to form or too thick to cut? Specifying a material thickness outside a supplier's capability can lead to costly redesigns, broken tooling, and major production delays.

As a general capability, we handle material thicknesses from as fine as 0.1mm (0.004”) for delicate electronics up to 12mm (nearly 0.5”) for robust structural components. However, the precise limit for your part depends heavily on the material type, part complexity, and press tonnage required.

I've been on both sides of this question—first as a buyer in the US trying to get clear answers, and now, for over 30 years, running Prime Metals. I can tell you that a simple number is never the full story. The real answer lies in understanding the interplay between your design and the physics of metal forming. Let's explore the factors that truly define our stamping capabilities for your project.

How is minimum thickness determined for thin-gauge stamping?

When you’re dealing with foils and shims, the challenges aren’t about force, but about finesse. Controlling ultra-thin materials requires specialized tooling and a deep understanding of their behavior.

The challenge of material springback and ductility

Thin materials, especially high-strength alloys, have a tendency to "spring back" or flex back toward their original shape after being formed. We have to precisely over-bend the material so it springs back into the correct angle. For materials thinner than 0.2mm, this requires incredibly tight control over the die, press speed, and material properties.

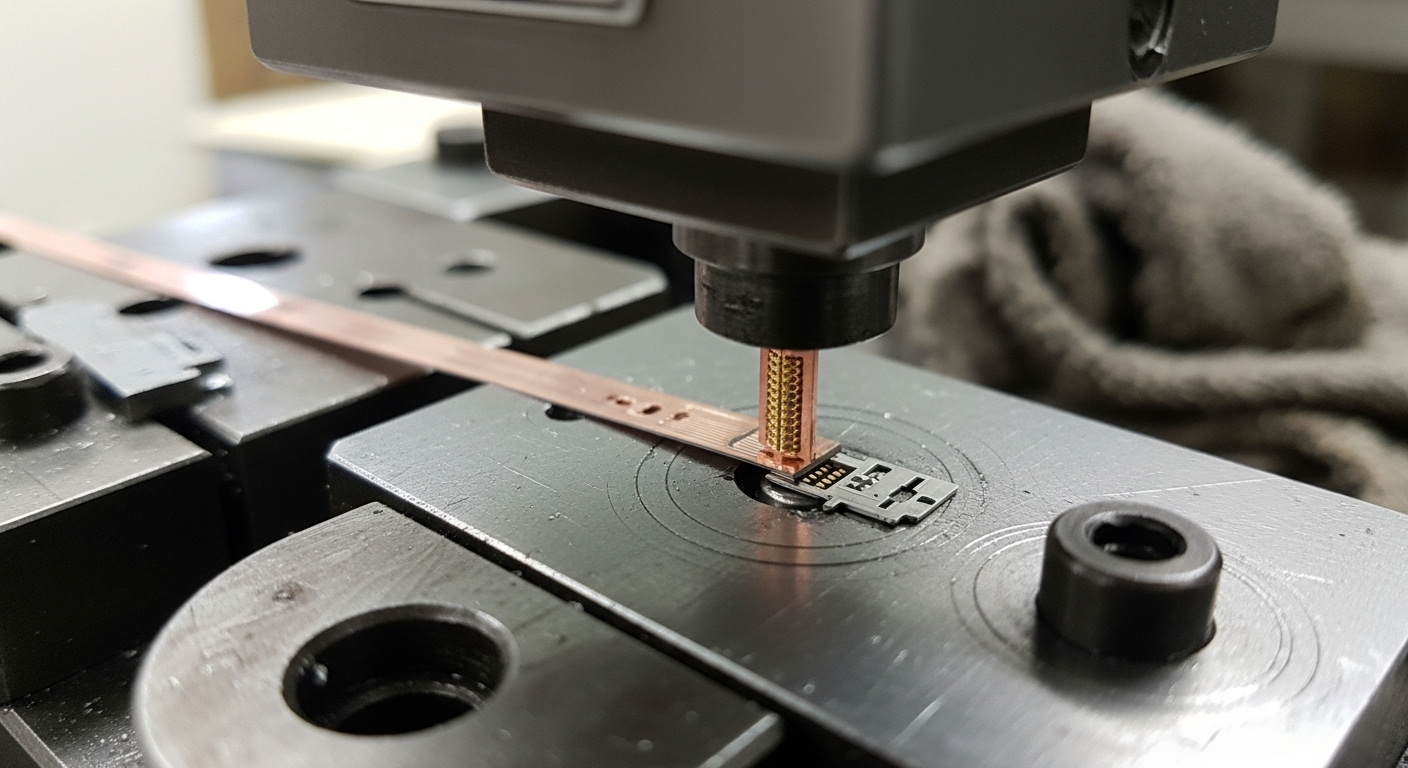

The necessity of precision tooling

For thin-gauge stamping, the clearance—the gap between the punch and the die—is microscopic. If it's too large, you get a burr; if it's too small, the tool wears out prematurely. Our toolmakers are experts at creating dies with clearances measured in microns to ensure a clean, burr-free cut on every stroke, even on the thinnest materials.

Common applications for fine and micro-stamping

We typically work with thin-gauge materials for industries that demand precision and miniaturization. This includes:

- Electronics: EMI/RFI shielding, battery contacts, lead frames, and connectors.

- Medical: Surgical instrument components and diagnostic device parts.

- Aerospace: Shims, gaskets, and lightweight brackets.

What press capabilities are needed for maximum thickness?

Stamping thick-plate metal is a game of immense force. The primary limiting factor is the tonnage, or the maximum force our presses can exert to shear and form the material.

The critical role of press tonnage

Shearing a 10mm-thick piece of steel requires incredible force. Our press fleet ranges from 25 tons for small parts up to 800 tons for heavy-gauge work. The required tonnage is a direct function of the material's shear strength and the total length of the cut. For any inquiry, our engineers first calculate the required tonnage to ensure we have the right machine for the job.

The importance of tooling strength and design

The force required to stamp thick metal doesn't just shape the part; it punishes the tool. Our heavy-gauge dies are constructed from robust tool steels like D2, with reinforced sections to withstand millions of high-impact cycles. Poor tool design is a major reason why less experienced suppliers fail when working with thick materials.

Examples of heavy-gauge stamping applications

Our high-tonnage capabilities are essential for industries that require strength and durability. We produce a wide range of custom stamping parts, including:

- Automotive: Frame components, suspension brackets, engine mounts.

- Construction: Structural connectors, base plates, heavy-duty hardware.

- Agriculture: Equipment frames and implement components.

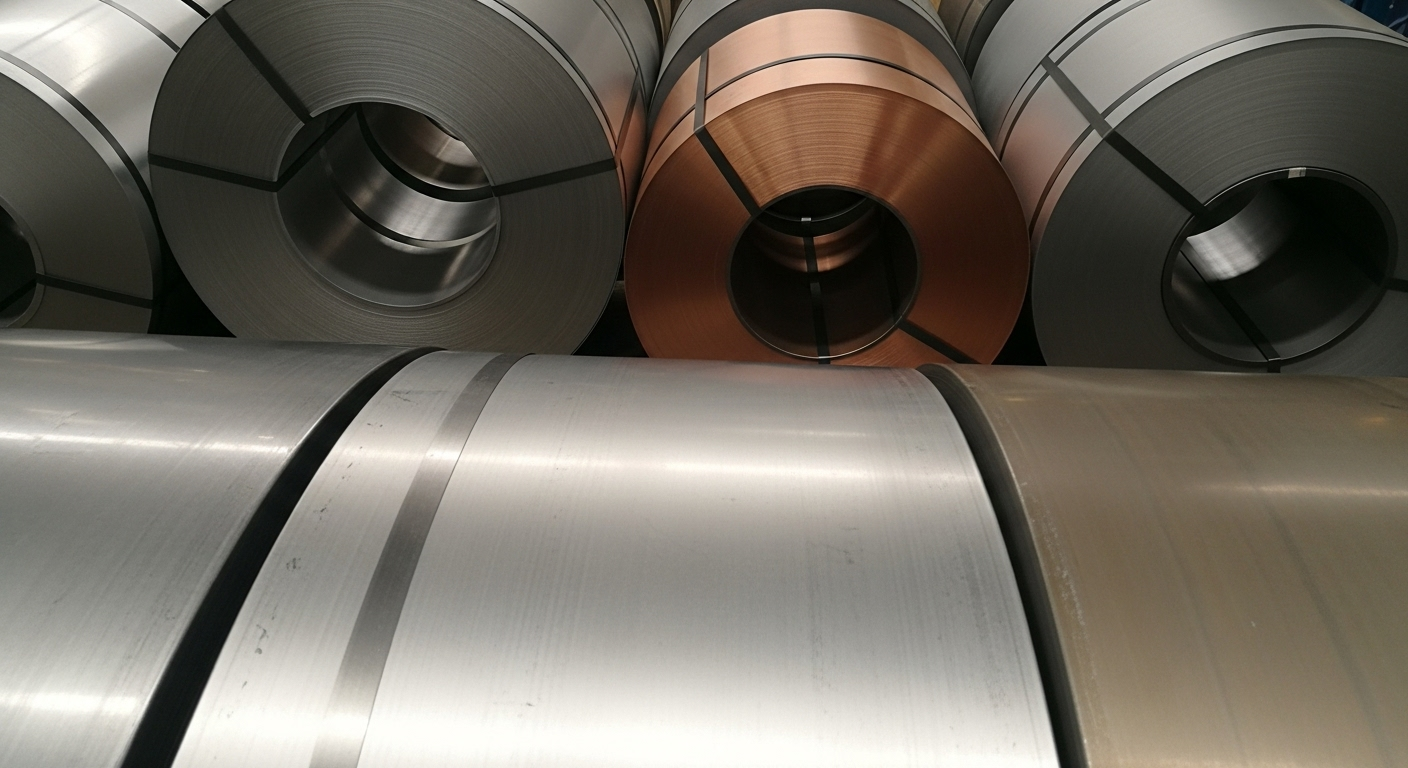

How does material type affect stamping thickness limits?

Not all metals are created equal. The material you choose has the single biggest impact on how thick we can practically stamp your part. A 5mm aluminum part is vastly different to stamp than a 5mm stainless steel part.

Stamping soft vs. hard materials

Softer materials like aluminum, copper, and mild steel have lower shear strength, meaning they require less tonnage to cut and form. This often allows us to stamp them at greater thicknesses on a given press. Harder materials, like high-strength steels and stainless steel, resist deformation and require significantly more force.Softer materials like aluminum, copper, and mild steel have lower shear strength, meaning they require less tonnage to cut and form. This often allows us to stamp them at greater thicknesses on a given press. Harder materials, like high-strength steels and stainless steel, resist deformation and require significantly more force.

A material-based thickness guide

This table gives a general idea of how material choice affects thickness capabilities. These are rough estimates; complex geometries can reduce these maximums.

| Material Type | Typical Maximum Thickness (on 800-Ton Press) | Key Stamping Considerations |

|---|---|---|

| Aluminum (5052) | ~ 12 mm (0.47") | Low force required, but prone to galling; needs lubrication. |

| Mild Steel (1018) | ~ 10 mm (0.39") | Very formable, predictable behavior, the industry baseline. |

| Stainless Steel (304) | ~ 6 mm (0.24") | High force required, work hardens quickly, high tool wear. |

| HSLA Steel | ~ 8 mm (0.31") | Higher force than mild steel, significant springback. |

Work hardening and its effects

Materials like stainless steel and some copper alloys "work harden" very quickly. As the material is bent and formed, it becomes harder and more brittle. For complex parts with multiple bends, we must account for this in the die design to prevent fractures, which can limit the practical thickness for deep-drawn or intricate geometries.

How does part complexity influence thickness constraints?

A simple flat washer is one thing; a complex deep-drawn housing is another entirely. The geometry of your part plays a huge role in determining the feasible thickness range.

Deep drawing vs. simple blanking

Blanking is simply cutting a 2D shape, so its limits are mostly tied to tonnage. Deep drawing involves stretching a metal blank into a 3D shape, like a can or a housing. For thick materials, the forces required to stretch the metal are enormous. For thin materials, the material is prone to wrinkling or tearing. There is a "sweet spot" for deep drawing that balances material thickness with the depth of the draw.

The impact of tight radii and sharp features

Bending thick metal around a sharp corner creates immense stress concentration. Trying to form a radius that is too tight for the material's thickness is a primary cause of cracking. As a general rule, acknowledged by organizations like the Precision Metalforming Association (PMA), the minimum inside bend radius should be at least equal to the material thickness.

Balancing features with material flow

In a progressive die, the metal flows and stretches from one station to the next. Part features must be designed to allow for this flow. Holes punched too close to a bend can become distorted. Narrow sections can create weak points that fail under the stress of forming, especially with thicker, less forgiving materials. Our Design for Manufacturability (DFM) review always analyzes these potential failure points.

How do we determine the right process for your project?

We don't expect you to be a stamping expert. Our job is to take your design and engineer a reliable, repeatable process to produce it. This is how we ensure success from the very first contact.

Step 1: RFQ and Design for Manufacturability (DFM) Review

When you send us your drawing and requirements, our engineering team immediately analyzes it. We calculate the required tonnage, assess the material, and look for any features that might pose a challenge, like tight radii or deep draws. We provide this feedback to you upfront.

Step 2: Material Selection and Tooling Strategy

Based on the DFM review, we confirm the material selection and map out the entire stamping process. Will it be a single-stage die or a multi-stage progressive die? What tool steel is required? This planning stage is crucial for ensuring quality and managing costs.

Step 3: Prototyping and First Article Inspection (FAI)

Before launching mass production, we produce a first article from the production tool. This part undergoes a rigorous inspection where we measure every single feature against your drawing. We provide you with a detailed FAI report for your approval, guaranteeing that our process is capable of producing your part perfectly before the main run begins.

About the Author

My name is Kevin. My career started in the US, sourcing industrial hardware and learning firsthand the costs of working with suppliers who couldn't deliver on their promises. Since 1993, I've applied those hard-won lessons to building Prime Metals. We've created a factory that combines robust engineering with the transparent communication and rigorous quality systems (like ISO 9001 and PPAP) that international buyers expect. We don't just sell parts; we provide manufacturing solutions.

Frequently Asked Questions (FAQs)

What is the difference between blanking and fineblanking?

Blanking is the standard process of cutting a shape from sheet metal. Fineblanking is a specialized, more precise method that uses a combination of high pressure and a v-ring to produce a fully sheared, straight edge with no fracture zone. It's used for high-precision components but is typically limited to materials under 12mm.

How does tonnage relate to material thickness?

Tonnage is the force the press exerts. The force needed is calculated by multiplying the perimeter length of the cut by the material thickness, then multiplying by the material's shear strength. Doubling the material thickness effectively doubles the tonnage required for a cut.

Can you stamp parts from pre-plated or coated materials?

Yes, we frequently work with pre-plated steel (like galvanized or electro-tin plated) and pre-coated aluminum. This is often more cost-effective than plating individual parts after stamping. Tooling must be designed carefully to protect the coating during the forming process.

What is "springback" and how do you control it?

Springback is the tendency of metal to return to its original shape after being bent. As explained by sources like Wikipedia on Bending, we compensate for it by "overbending" the part by a precise amount, which is determined by the material type, thickness, and bend radius.

Ready to Start Your Project?

Navigating the complexities of material thickness, tonnage, and tooling is our expertise. You provide the design, and we'll engineer a robust, cost-effective stamping solution to bring it to life.

Let our team review your project and provide a clear path to production.