How does Prime ensure dimensional accuracy and surface finish quality in CNC machining?

Have you ever received a batch of CNC parts where the first one was perfect, but the last one caused a failure in assembly? Inconsistent quality is a plague that can shut down your production line and destroy your profit margins.

We ensure quality through a three-part system: rigorous pre-production planning (DFM), in-process control using advanced tools and calibrated machines, and final verification in a temperature-controlled quality lab with CMMs and profilometers to certify every dimension and finish.

Years ago, as a buyer in the US, I battled suppliers over out-of-spec parts. The excuses were endless. That's why when I established Prime Metals in 1993, I built our quality system around one idea: control the process, and you control the part. Quality isn't just a final inspection; it's a discipline that starts the moment we receive your RFQ. Let’s break down how we guarantee the parts you receive are exactly the parts you designed.

What happens before a single chip is cut?

The most common point of failure in CNC machining happens before the machine is even turned on. Rushing into production without proper planning is a recipe for scrap.

Step 1: Design for Manufacturability (DFM) Review

The first thing our engineers do is analyze your design not just for possibility, but for repeatability. Can that sharp internal corner be made with a small radius to improve tool life and strength? Is that tolerance truly necessary, or can it be opened up to reduce cost without affecting function? We provide this feedback upfront to prevent problems and optimize your design for production.

Step 2:

Verifying Raw Materials

You can't make a good part from bad material. Every batch of raw material that enters our facility—be it aluminum 6061, stainless 304, or titanium—is accompanied by a material certificate from the mill. We verify its chemical composition and properties against the spec. This step, a core requirement of our ISO 9001:2015 certification, ensures the foundation of your part is solid.

Step 3:

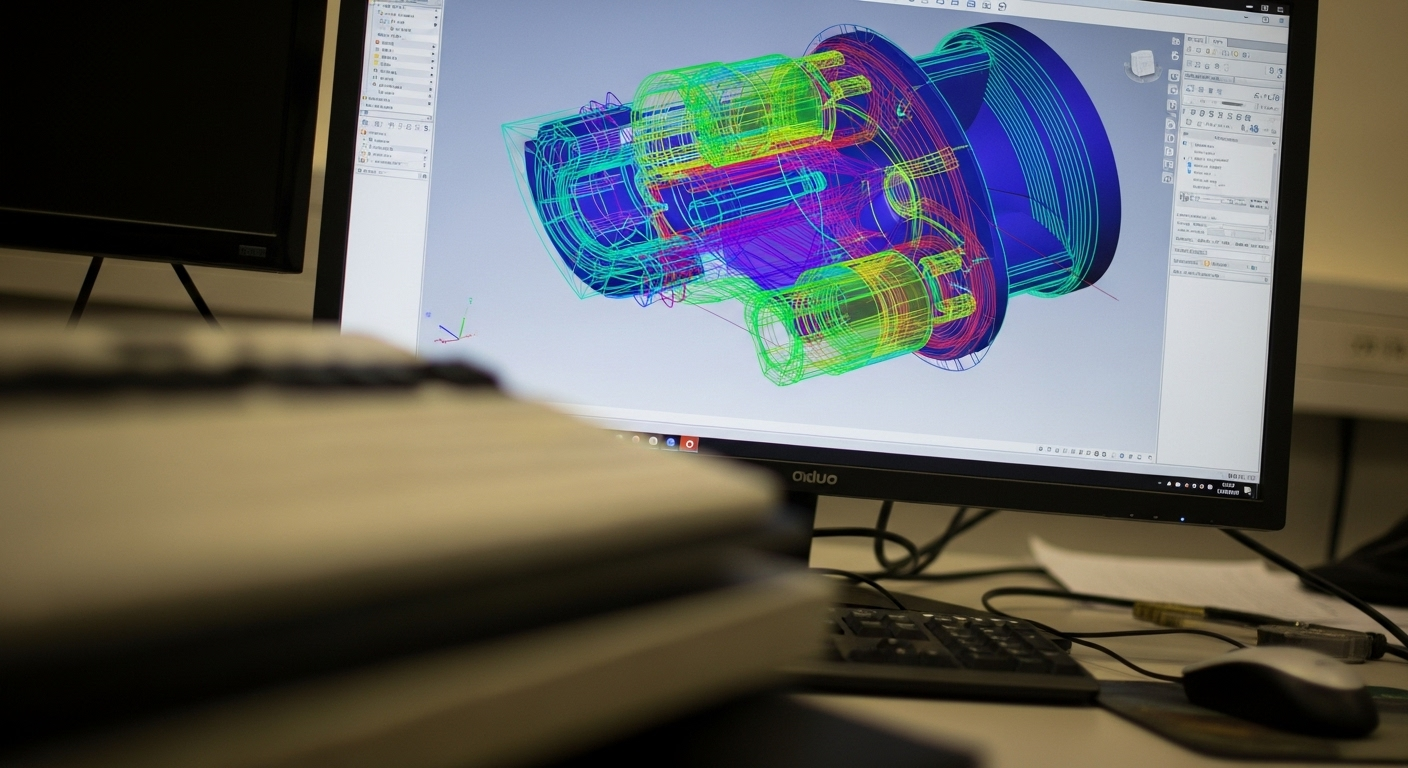

CAM Programming and Digital Simulation

Our programmers use advanced CAM (Computer-Aided Manufacturing) software to generate the toolpaths. Before sending the code to the machine, they run a complete digital simulation. This virtual machining process allows us to spot potential tool collisions, inefficient movements, or areas where the tool might create a poor surface finish. This catches errors on the screen, not on your expensive part.

What in-machine technology maintains precision during cutting?

A great program is useless without a capable machine and precise tooling. The hardware we use is a critical link in the quality chain for all our CNC machined parts.

Maintained, High-Performance CNC Machines

We invest in rigid, well-maintained CNC machines. Why? Because a machine that vibrates or has worn ball screws cannot hold a tight tolerance. Regular preventative maintenance, laser calibration, and thermal compensation on our machines ensure that a command for 10.000mm results in a 10.000mm cut, from the first part of the day to the last.

Precision Workholding and Cutting Tools

Even the best machine can't make a good part if the workpiece moves or the cutting tool is worn. We use robust hydraulic or custom-machined fixtures to hold parts rigidly. Furthermore, we manage our tool library meticulously, using high-quality carbide tools and replacing them based on strict usage counts, not just when they break. This prevents defects caused by a dull cutting edge.

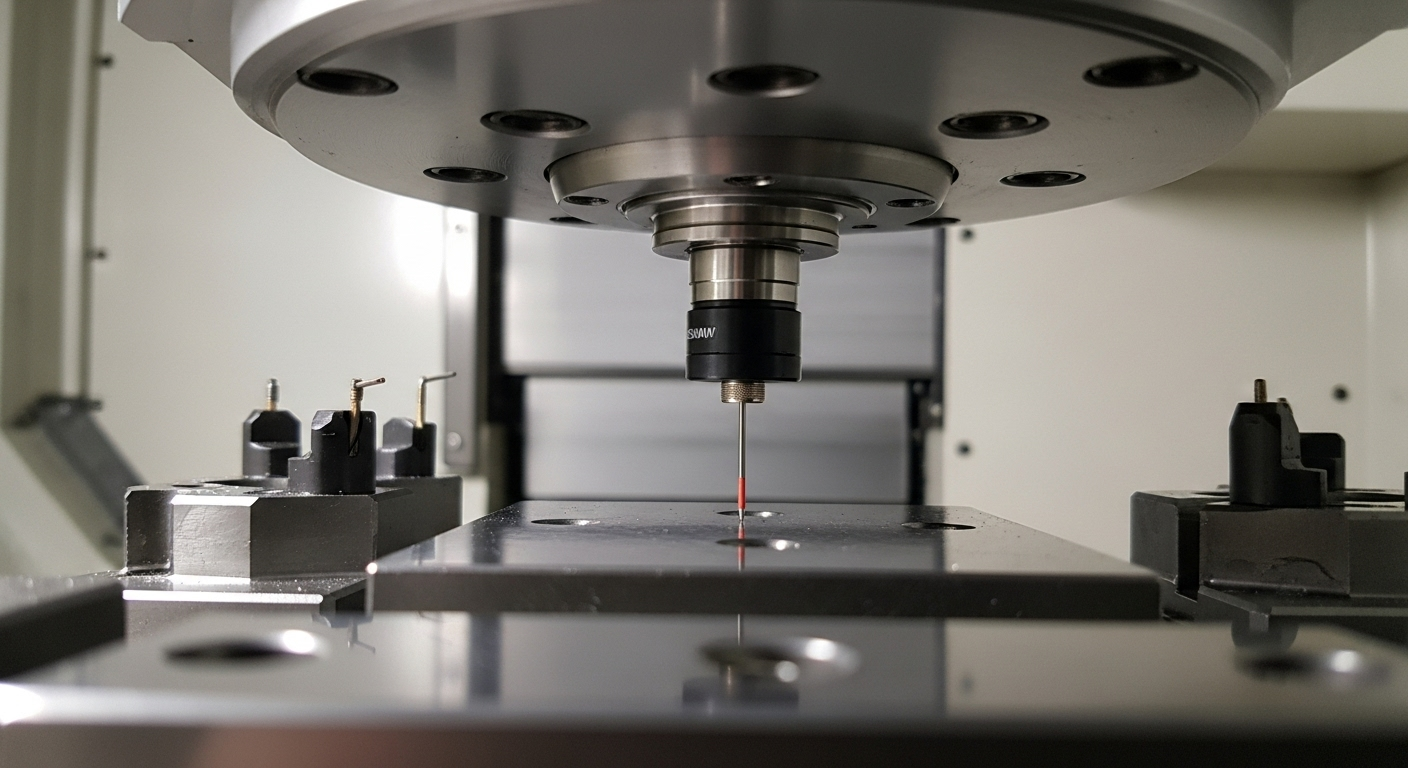

In-Machine Probing for Setup and Inspection

Modern CNC machines can check their own work. We use in-machine probing systems to automatically locate the part with extreme precision (known as setting the work offset). The probe can also be used to measure critical features mid-cycle, allowing the machine to automatically adjust for tool wear and ensure every single part remains within the tolerance band.

How do we control and verify the surface finish?

Dimensional accuracy is about fit, but surface finish is about function—how a part seals, wears, or even looks. A part that's the right size but has the wrong texture can still fail.

Understanding Surface Roughness (Ra)

Surface finish is typically measured in Ra (Roughness Average), as defined by standards like ISO 21920. This number quantifies the microscopic peaks and valleys on a part's surface. A low Ra value (e.g., 0.8 μm) indicates a smooth, fine finish, essential for sealing surfaces or bearing journals. A higher Ra (e.g., 3.2 μm) is a standard machined finish.

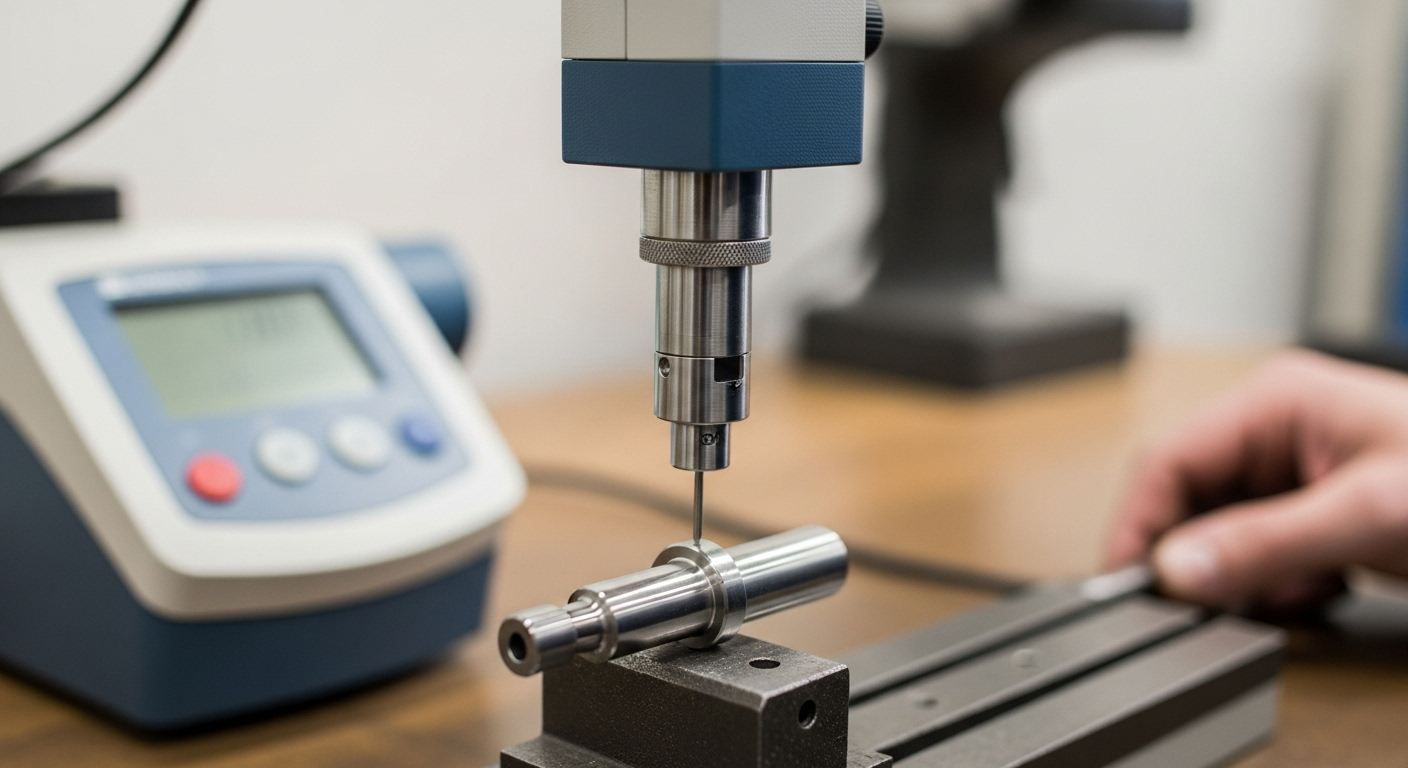

How we Measure Finish

We don't guess. We verify surface finish using a calibrated profilometer. This instrument drags a diamond-tipped stylus across the surface to physically measure the topography and provide a definitive Ra value. For quick visual checks on the shop floor, operators use surface finish comparator blocks.

How we Control Finish

Achieving a specific Ra is a science. It's a direct result of the machining parameters we program. A fine finish requires a different approach than rough cutting.

| Desired Finish | Tool Selection | Speed (SFM) | Feed Rate (IPR) |

|---|---|---|---|

| Roughing (Ra 3.2+) | Large, robust insert | Moderate | High |

| Standard (Ra 1.6) | Sharp, general-purpose | High | Moderate |

| Fine (Ra 0.8-) | Wiper insert, small radius | Very High | Low |

How do we guarantee quality throughout the entire production run?

A perfect first part is just the beginning. True quality control means the 10,000th part is identical to the first. This is achieved through systematic in-process checks.

First-Off Inspection Approval

No production run begins until the very first part off the machine is taken to our quality lab and undergoes a full inspection. We verify every dimension against the drawing. Only after the quality manager signs off on this "First-Off Inspection" is the operator authorized to start the full run.

In-Process Checks by the Operator

Our machine operators are our first line of defense. At defined intervals (e.g., every 10th part), they perform checks on critical dimensions using calibrated gauges and micrometers right at their workstation. These results are logged, allowing us to use Statistical Process Control (SPC) to monitor trends and make adjustments before a part ever goes out of spec.

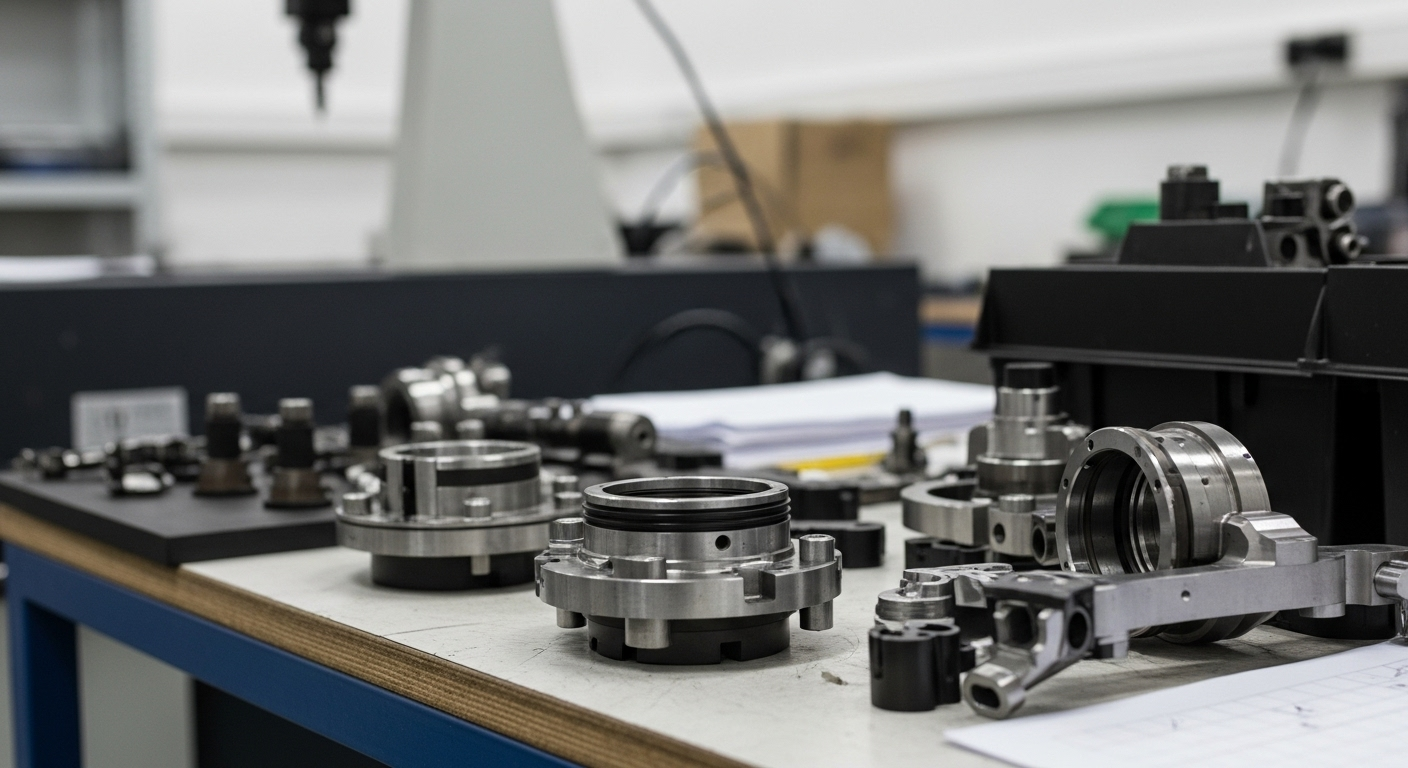

Final Inspection and Documentation

A final, random sample from every completed batch is sent for a concluding inspection in our temperature-controlled quality lab. We use our CMM (Coordinate Measuring Machine) to verify complex GD&T callouts. The result is a complete inspection report, which we can supply with your shipment, giving you full confidence and traceability.

What is the final step in ensuring part quality?

Even a perfect part can be ruined before it reaches you. The final, and often overlooked, step of quality control is ensuring the part arrives safely at your facility.

Meticulous Deburring and Cleaning

After machining, every part goes through a deburring and cleaning process. We remove any sharp edges or burrs left by the cutting tools and ensure parts are free of coolant and chips. This is critical for both operator safety and the part's final function.

Corrosion Prevention

For materials like steel that can rust, this step is vital. Parts are either treated with a rust-preventative oil or sealed in VCI (Vapor Corrosion Inhibitor) bags. This ensures they arrive in pristine, factory-fresh condition, even after a long sea journey.

Custom Protective Packaging

We never just throw parts in a box. We design custom packaging solutions using foam inserts, dividers, or individual wrapping to prevent parts from scratching or denting each other during transit. For a sensitive part, the packaging is as important as the machining itself. When you need parts, contact us and we will take care of everything.

About the Author

My name is Kevin. I began my career in the United States, sourcing complex industrial components and experiencing the high cost of poor quality firsthand. Since establishing Prime Metals in 1993, I have dedicated myself to building a factory that operates on a foundation of process control and transparency. We integrate the rigorous quality systems that Western buyers demand, ensuring that what you see on the print is what you get in the box.

Frequently Asked Questions (FAQs)

What is the tightest tolerance you can hold in CNC machining?

For most features, we can comfortably hold tolerances of +/- 0.025mm (+/- 0.001"). For critical applications like bearing fits or precision shafts, we can achieve tighter tolerances through secondary grinding or honing operations. The achievable tolerance always depends on the part geometry and material.

What is a CMM?

A CMM, or Coordinate Measuring Machine, is a highly precise device that uses a probe to measure the geometry of an object in a 3D coordinate system. It is essential for accurately verifying complex GD&T (Geometric Dimensioning and Tolerancing) features that cannot be measured with calipers or micrometers.

Does the material type affect the achievable surface finish?

Yes, absolutely. Softer materials like aluminum and brass can typically achieve a very fine, almost mirror-like finish more easily. Harder materials like stainless steel or Inconel require more specific tooling and parameters to achieve a low Ra value and are more prone to showing tool marks.

What is a Certificate of Conformance (CoC)?

A Certificate of Conformance is a document we issue that certifies that the supplied parts have been produced and inspected according to the requirements of your drawing and purchase order. It provides formal assurance and traceability for your quality records.

Your Partner for Precision

Achieving consistent dimensional accuracy and surface finish isn't an accident. It's the result of a deliberate, multi-layered system of process control, advanced technology, and a dedicated team.

Stop gambling with your supply chain. Let's discuss how our quality system can deliver the reliable, high-quality CNC parts your products deserve.