How Does Cast Aluminum Compare to Forged or CNC Machined Aluminum?

Are you struggling to choose the right manufacturing process for your aluminum part? Selecting the wrong one can lead to parts that are too weak, too expensive, or impossible to produce at scale.

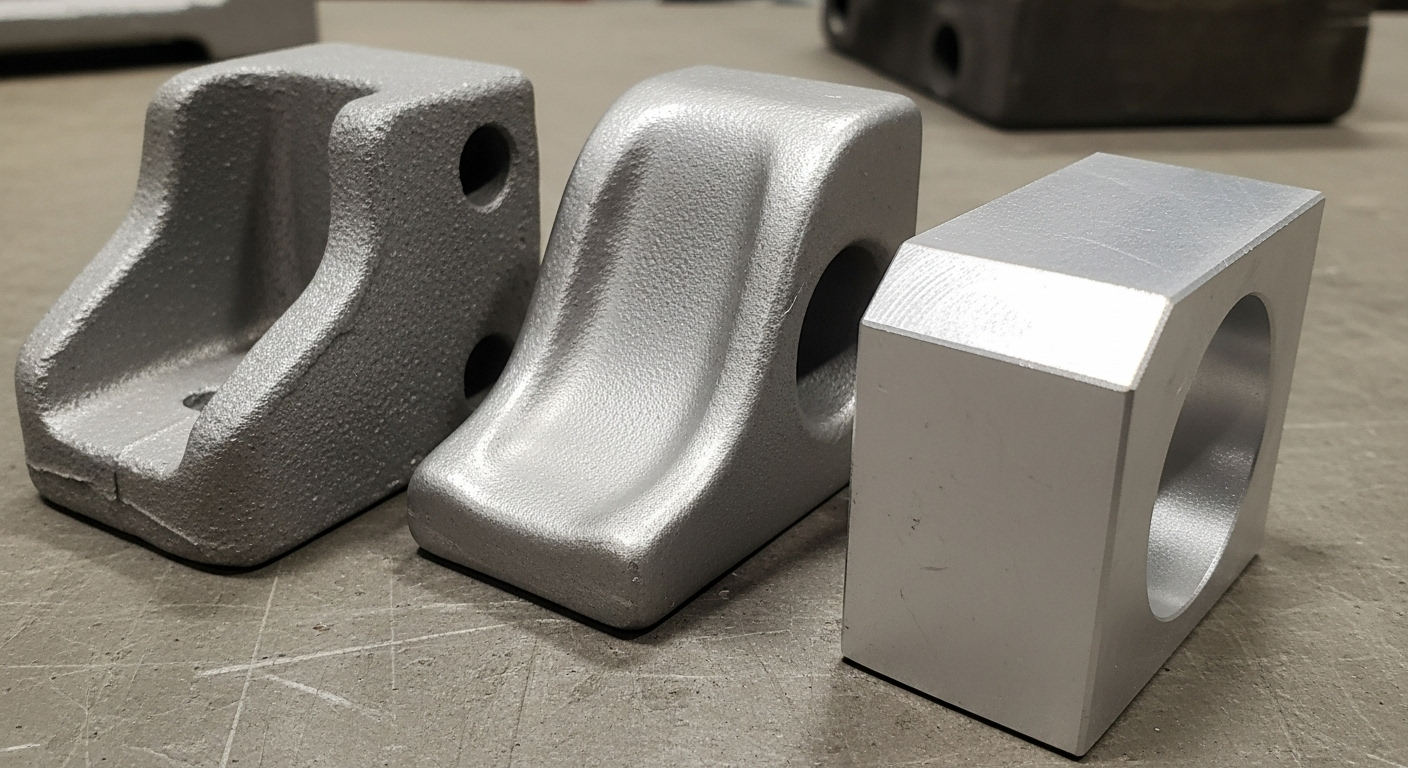

The choice depends on your priorities. Casting excels at creating complex shapes for high-volume production at a low piece price. Forging delivers the highest possible strength. CNC machining offers ultimate precision and design flexibility, ideal for prototypes and low-volume runs.

As a buyer in the US, I saw multi-million dollar projects get derailed by this exact choice. Now, running Prime Metals for over 30 years, I see it from the other side. Engineers often default to what they know, not what's best for the part's function and budget. Understanding the core trade-offs between pouring molten metal, squeezing a solid billet, and carving it away is the most important decision you'll make.

How are these three processes fundamentally different?

It's easy to get lost in technical jargon, but the difference between these methods is simple. Are you melting metal and pouring it, squeezing it into shape, or cutting it away from a solid block?

Casting involves pouring molten aluminum into a mold. Forging uses immense pressure to shape a solid aluminum billet. CNC machining is a subtractive process, cutting a final shape out of a solid block of aluminum.

Aluminum Casting: The Liquid State

In casting, we start by melting aluminum ingots into a liquid. This molten metal is then poured or injected into a precision mold or die. As it cools, it solidifies into the shape of the mold, creating the "net shape" of the part. This method is like making ice cubes—you start with a liquid and end with a solid in a predefined shape. Our expertise in aluminum casting allows for intricate and complex designs.

Aluminum Forging: The Plastic State

Forging starts with a solid block of aluminum, called a billet or ingot. We heat this billet until it is malleable but not molten. Then, we use a powerful press or hammer to squeeze or strike the billet between two custom-shaped dies. This immense pressure forces the metal to flow and conform to the shape of the dies, a process detailed by industry sources like the Forging Industry Association.

CNC Machining: The Solid State

CNC (Computer Numerical Control) machining starts with a solid block or bar of a specific aluminum alloy, often called "billet." The block is secured in a machine, and a computer-controlled cutting tool (like an end mill or drill) removes material layer by layer to reveal the final shape. It is a "subtractive" process, like a sculptor carving a statue from a block of marble. It is the core of our CNC parts manufacturing.

Which process produces the strongest parts?

Your part just failed in the field, and a product recall is looming. This nightmare scenario is often the result of choosing a process that couldn't provide the required mechanical strength and fatigue resistance.

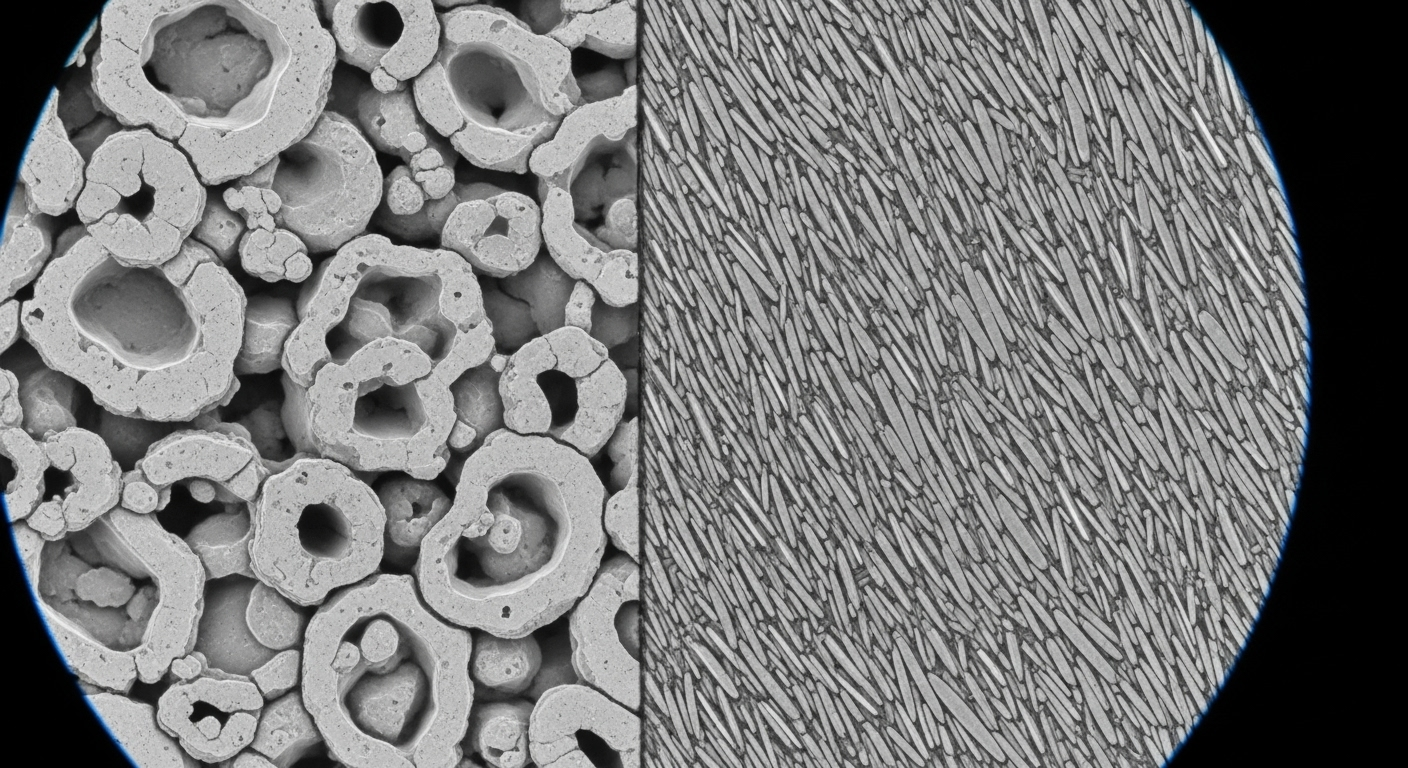

Forging produces the strongest, most durable aluminum parts by a significant margin. This is because the forging process refines and aligns the metal's internal grain structure, eliminating defects and creating a continuous grain flow that follows the part's contour.

The Unmatched Strength of Forging

Imagine the grain in a piece of wood. A forged part is like a bent piece of solid wood—the grain flows along the curve, making it incredibly strong. The forging process forces the aluminum's internal grains to align with the part's shape, creating exceptional tensile strength, impact resistance, and fatigue life. This makes it the go-to process for critical components like aircraft landing gear and automotive suspension parts.

The Reliability of CNC Machining

A CNC machined part is cut from a solid billet of wrought aluminum, which already has a very strong, uniform grain structure from the rolling or extrusion process. While machining cuts across these grain lines, the part retains the inherent high strength and integrity of the original material. There are no internal voids or porosity, making it very reliable and significantly stronger than a casting.

The Known Weakness of Casting

When molten aluminum cools and solidifies in a mold, its grain structure is random and non-uniform, like a bowl of granola. More importantly, microscopic gas pockets (porosity) can get trapped during the cooling process, creating internal weak spots. While modern casting techniques minimize this, a cast part will inherently have lower tensile strength and be more brittle than a forged or machined part.

| Process | Grain Structure | Relative Strength | Key Weakness/Limitation |

|---|---|---|---|

| Forging | Aligned, refined | Highest | Limited geometric complexity |

| CNC Machining | Uniform, but cut | High | High material waste & cost |

| Casting | Random, non-uniform | Lower | Potential for porosity |

What are the limits on part geometry and complexity?

You've designed the perfect part in your CAD software, but now your supplier says it's impossible to make. The limitations of the manufacturing process can put a hard stop on even the most innovative designs.

Casting offers the greatest design freedom, easily producing highly complex, intricate shapes with internal cavities. Forging is the most restrictive, suitable for simpler, blockier shapes. CNC machining is highly flexible but is limited by cutting tool access.

Casting's Unmatched Design Freedom

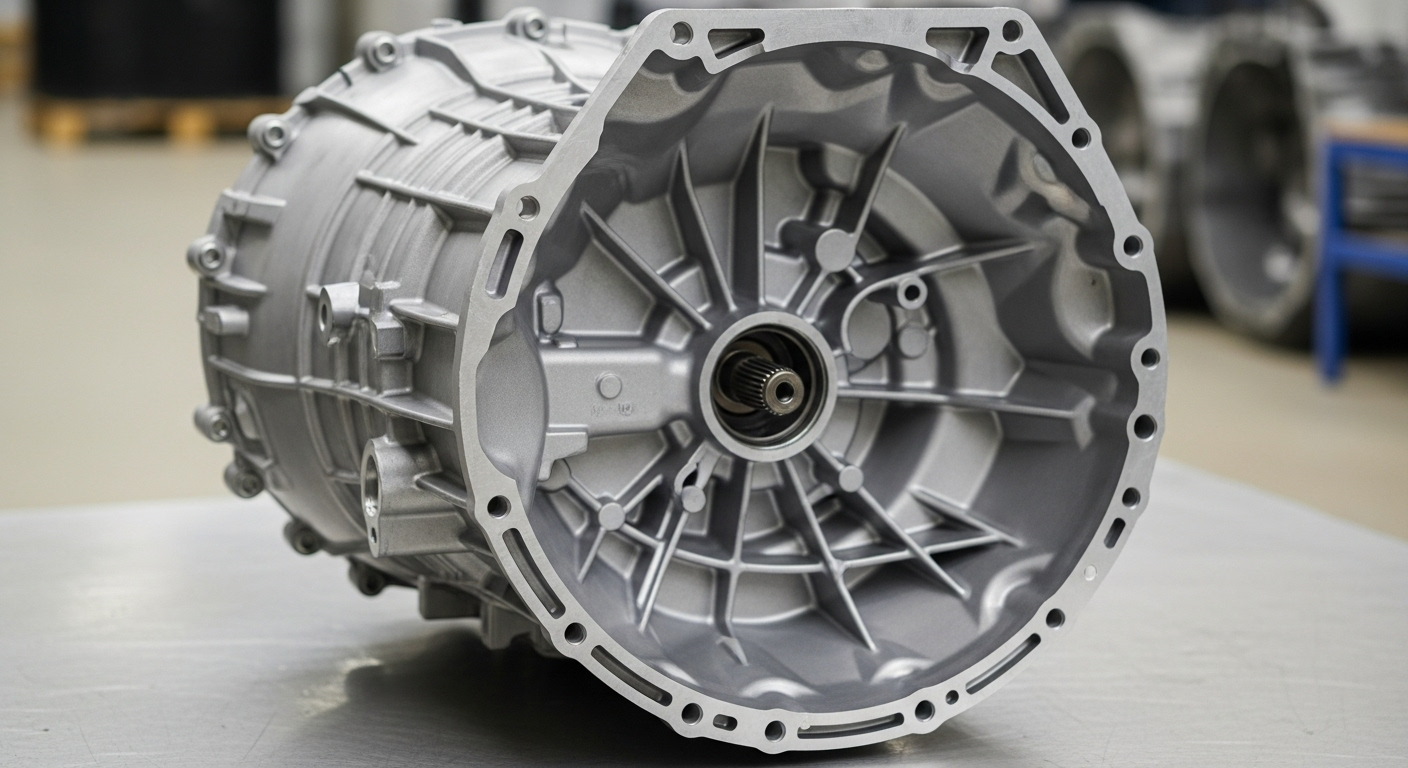

Because we start with a liquid, we can make it flow into almost any shape imaginable. This allows for complex internal channels, very thin walls, and intricate, organic geometries. Parts like engine blocks or gearbox housings are almost always cast because it's the only economical way to create their complex internal and external features in one piece.

Forging's Geometric Constraints

The forging process requires the part to be removable from the die, which means generous radii and "draft angles" (slight tapers) are necessary on all vertical surfaces. It is very difficult and often impossible to create sharp internal corners, undercuts, or complex internal features. Forging is best for parts that require maximum strength but have a relatively simple, solid geometry.

CNC Machining's Precision Flexibility

CNC machining can produce features with incredible precision and very sharp corners. As described by sources like Wikipedia on CNC, it is highly flexible and can create almost any geometry you can model. The main limitations are tool access—a cutting tool cannot create a feature it cannot physically reach—and the fact that every complex surface adds significant time and cost to the process.

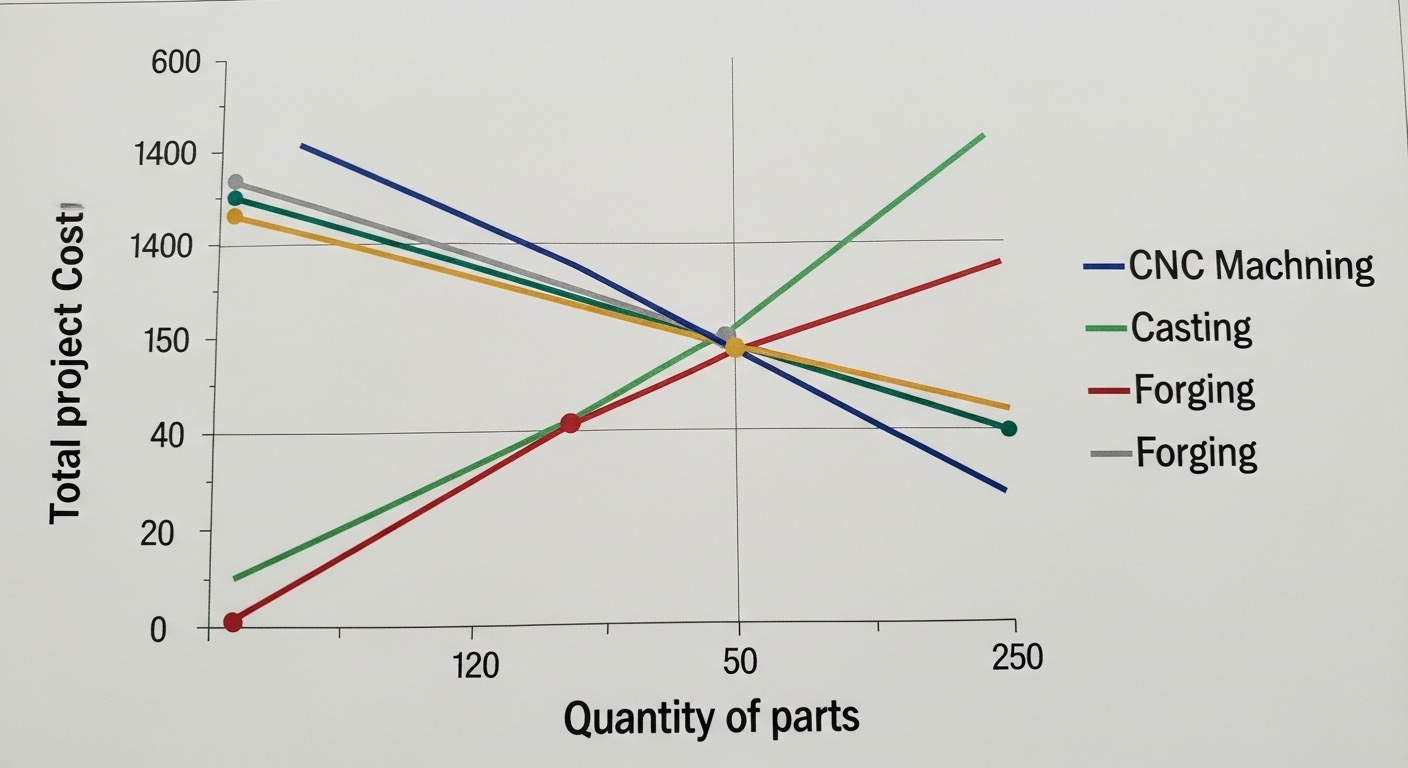

How do tooling costs and production volume affect the price?

You've received two quotes for the same part: one is $500 and the other is $50,000. This massive difference is almost always down to tooling costs and the intended production volume. Understanding this is key to budgeting your project.

CNC machining has zero tooling cost, making it ideal for prototypes, but a high piece price. Casting and forging have extremely high upfront tooling costs (for the mold or die), but a very low piece price, making them economical only for high-volume production.

The "Pay-as-You-Go" Model of CNC

For CNC machining, the primary costs are material, machine time, and programming. There is no mold to create. This means you can order one part or one hundred parts and the piece price remains relatively stable. It's the perfect choice for prototyping, design validation, and low-volume production runs (typically 1-1,000 pieces).

The High Investment of Casting & Forging

Creating a hardened steel die for die casting or forging is a complex and expensive process, often costing tens of thousands of dollars. This is a one-time "tooling" investment you must make before the first part is ever produced. This high upfront cost makes these processes completely unsuitable for small quantities.

The Breakeven Point

The high tooling cost of casting and forging is amortized over the entire production run. If a die costs $50,000 and you make 100,000 parts, you've added only $0.50 of tooling cost to each part. This, combined with a very low piece price, makes casting and forging the only viable options for mass production (typically 10,000+ pieces). We can help you analyze this breakeven point when you contact our team.

| Process | Tooling / Setup Cost | Unit Part Cost | Ideal Production Volume |

|---|---|---|---|

| CNC Machining | Very Low / None | High | 1 - 1,000 |

| Casting | Very High | Very Low | 5,000 - 1,000,000+ |

| Forging | Very High | Low | 10,000 - 1,000,000+ |

How do I choose the right process for my aluminum part?

You have a design, a budget, and a production goal. Now it's time to make the final decision. Don't get stuck; use these simple guidelines to point you in the right direction.

Make your choice based on your primary constraint: for ultimate strength, choose forging. For complex shapes in high volume, choose casting. For prototypes, low volume, or the highest precision, choose CNC machining.

Choose CNC Machining When...

Your priorities are speed for initial samples, design verification, or ultimate precision. If you need 1 to 500 parts, or if your part has features with extremely tight tolerances (as defined by standards like ISO 2768), CNC machining is your best and often only choice.

Choose Casting When...

Your part is geometrically complex, will be produced in very high volumes (thousands or millions), and does not require the absolute highest level of strength. Housings, enclosures, decorative hardware, and many automotive components are perfect applications for casting.

Choose Forging When...

The absolute priority is strength and reliability under high stress or impact. If part failure would be catastrophic, forging is the answer. Think critical automotive suspension components, aerospace structural parts, and high-pressure valves. The part must have a relatively simple shape and be needed in high volumes to justify the tooling cost.

About the Author

My name is Kevin. I spent the first half of my career in the U.S. sourcing industrial components, where I learned the costly lessons of mismatched designs and manufacturing processes. Since founding Prime Metals in 1993, I’ve built our factory on the principle of partnership. We are ISO 9001 certified, and we guide our clients to the optimal manufacturing solution, ensuring the final product is not just made to spec, but is also a success in the real world.

Frequently Asked Questions (FAQs)

Can you CNC machine a cast or forged part?

Yes, this is very common. Many parts start as a "net shape" casting or forging and then go into a CNC machine for secondary operations to create high-precision features like threaded holes, flat mating surfaces, or tight-tolerance bores.

What is "porosity" in aluminum casting?

Porosity refers to tiny, empty voids or gas bubbles that can get trapped within the metal as it cools and solidifies. It's a natural byproduct of the casting process and a primary reason why castings are inherently weaker than solid, wrought materials.

Which aluminum alloys are used for each process?

For CNC machining, 6061-T6 is the most common all-purpose alloy, while 7075 is used for high-strength applications. For casting, A380 is a popular die-casting alloy. For forging, alloys like 6061 and 7075 are also commonly used, but in their "-T6" or other heat-treated tempers.

What is a "billet"?

A billet is a solid length of metal (in this case, aluminum) that has been extruded or rolled into a standard shape, like a round bar or a rectangular block. It is the raw material stock used for both CNC machining and forging.

Let's Build Your Part the Right Way

Choosing the correct manufacturing process is fundamental to the success of your project. It impacts cost, performance, and scalability. Don't make the decision alone.

Our team has decades of experience across all three processes. Let us review your design and provide a comprehensive manufacturing plan.