Melting Point of Plastic: A Complete Guide for Industrial Buyers and Material Engineers?

Your new plastic component just warped and failed in the field because it was installed near a heat source. Now you're facing product recalls and a damaged reputation, all because of one misunderstood material spec.

For plastics, "melting point" is complex. Thermoplastics have a specific melt temperature (Tm) for processing, but their actual heat resistance in a product is better measured by the Heat Deflection Temperature (HDT), which indicates when a part will deform under load.

Why is 'Melting Point' in Plastics More Complicated Than in Metals?

You're used to metals having a single, precise melting point where they turn from solid to liquid. But with plastics, terms like "softening point" and "glass transition" get thrown around, causing confusion.

Plastics are divided into two families: thermoplastics, which melt and can be remolded, and thermosets, which char and burn instead of melting. Within thermoplastics, thermal behavior differs greatly between crystalline and amorphous types, making a single "melting point" misleading.

Thermoplastics vs. Thermosets

This is the most fundamental divide. Thermoplastics (like ABS, Polycarbonate, Nylon) can be heated to their melting point, cooled, and re-melted again without significant degradation. This makes them ideal for injection molding. Thermosets (like epoxy, silicone, polyurethane) undergo an irreversible chemical change when heated. They cure into a solid state and will not melt again; they will simply burn.

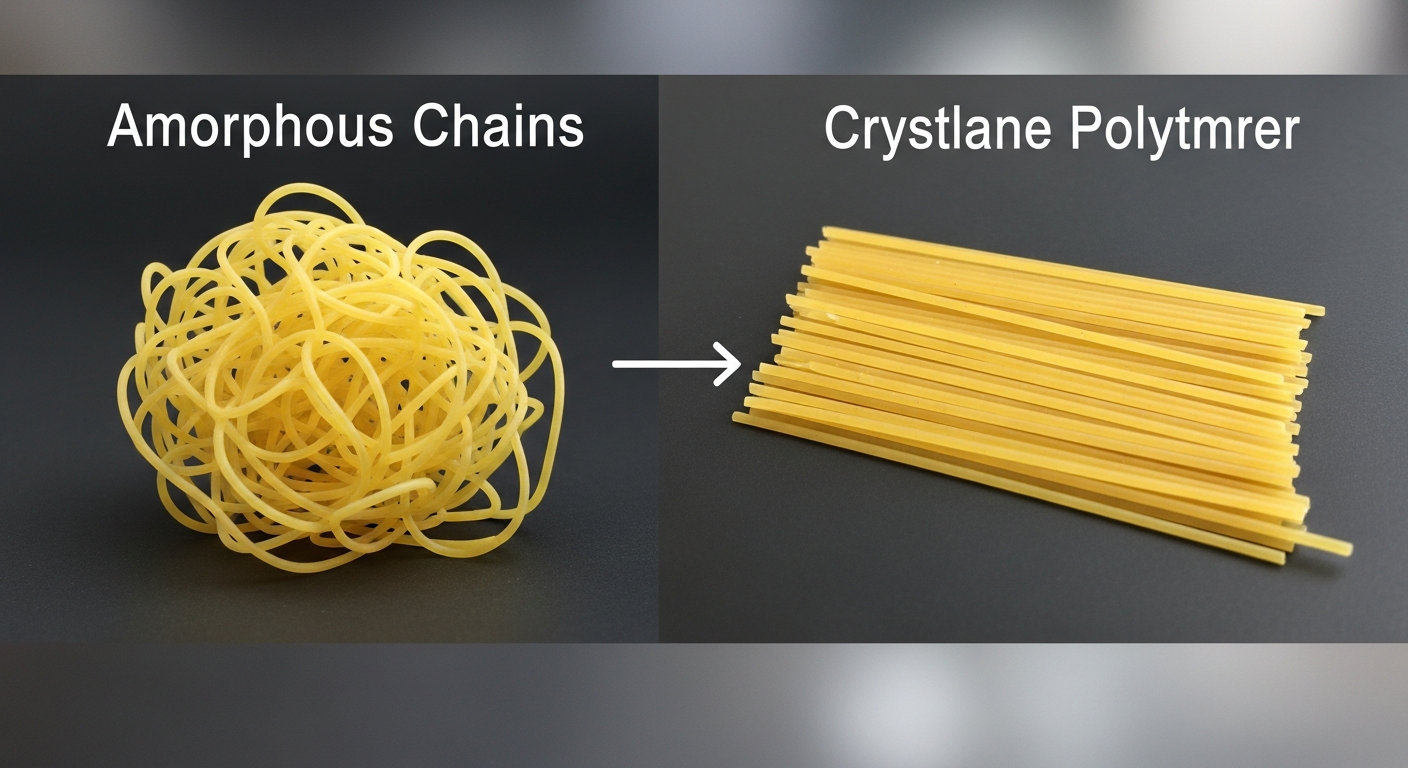

Crystalline vs. Amorphous Thermoplastics

This is where the real complexity begins.

- Amorphous plastics (like PC, ABS) have a random, tangled molecular structure. They don't have a true melting point. Instead, they have a Glass Transition Temperature (Tg), where they go from a hard, glassy state to a soft, rubbery one.

- Crystalline plastics (like Nylon, PP) have an ordered, structured molecular chain. They have both a Glass Transition Temperature (Tg) and a sharp, distinct Melt Temperature (Tm) where the crystalline structures break down and the material becomes a liquid.

Practical Definitions for Buyers

| Term | Abbreviation | Applies To | What It Means for You |

|---|---|---|---|

| Glass Transition Temp | Tg | All Thermoplastics | The point where the plastic softens and loses rigidity. |

| Melt Temperature | Tm | Crystalline Thermoplastics | The point where the plastic becomes a liquid for molding. |

| Heat Deflection Temp | HDT | All Thermoplastics | The true indicator of a part's structural stability at high temps. |

How Does Melting Temperature Impact the Injection Molding Process?

You've specified a high-temp plastic like PEEK for your part, but the quotes you're getting are high. The reason often lies in the extreme processing temperatures required, which affects everything from energy costs to cycle times.

The melting point dictates the core parameters of the injection molding process, including barrel temperature, mold temperature, and required drying time. Incorrect settings lead to defects like short shots, burn marks, or weak parts.

Setting the Barrel Temperature

The barrel of the injection molding machine is where the plastic pellets are melted. The temperature must be set well above the plastic's Tg and, for crystalline plastics, its Tm. If it's too low, the plastic won't flow properly, leading to incomplete parts ("short shots"). If it's too high, the material can degrade, losing its mechanical properties and causing discoloration or "burn marks".

Mold Temperature and Cycle Time

The mold is also heated or cooled to a specific temperature. A warm mold helps the molten plastic flow into intricate details, while a cool mold helps the part solidify faster. This cooling phase is often the longest part of the injection molding cycle. Plastics with high melting points require more energy to melt and often more time to cool, which leads to longer cycle times and a higher piece price.

Pre-Molding Material Drying

Many plastics, especially nylons and polycarbonates, are "hygroscopic," meaning they absorb moisture from the air. If these pellets are melted without being properly dried first, the trapped water turns to steam, causing bubbles, streaks, and severe brittleness in the final part. Plastics with

How Do You Match a Plastic's Heat Resistance to its Application?

The data sheet says your plastic's melting point is 220°C, but the part deformed in an environment that was only 120°C. This common failure happens because melting point is a processing metric, not a performance one.

For real-world performance, ignore the melting point and focus on the Heat Deflection Temperature (HDT). HDT is the temperature at which a standard test bar of the plastic will begin to deform under a specific load, making it the best indicator of structural performance at high temperatures.

The Critical Role of Heat Deflection Temperature (HDT)

The HDT test is defined by standards like ISO 75. It tells you at what temperature the material loses its rigidity and starts to bend. This is the number an engineer must use when designing a plastic part that will be under any kind of physical stress in a warm environment, such as an engine cover, a housing for electronics, or a component in a hot-water system.

Continuous Use Temperature (CUT)

For parts that will be exposed to high heat for their entire service life (thousands of hours), you need to consider the Continuous Use Temperature. This is a lower rating than HDT and indicates the maximum temperature the material can withstand long-term without significant degradation of its properties. Reputable material suppliers like DuPont or SABIC provide this data.

Common Plastics and Their Thermal Properties

| Plastic Material | Type | Melt Temp (Tm) Approx. | HDT @ 0.45 MPa Approx. | Common Use |

|---|---|---|---|---|

| ABS | Amorphous | N/A (Tg ~105°C) | 98°C | Electronic housings, consumer goods. |

| Polycarbonate (PC) | Amorphous | N/A (Tg ~150°C) | 130°C | Lenses, safety glasses, machine guards. |

| Nylon 6/6 (PA66) | Crystalline | 265°C | 90°C (Unfilled) | Gears, bearings, structural components. |

| PEEK | Crystalline | 343°C | 152°C (Unfilled) | Aerospace, medical, high-performance seals. |

Can Additives and Fillers Change a Plastic's Melting Point?

You've received a quote for a "glass-filled nylon" part that is much more capable in high heat than the standard version. Understanding how additives work is key to specifying cost-effective, high-performance materials.

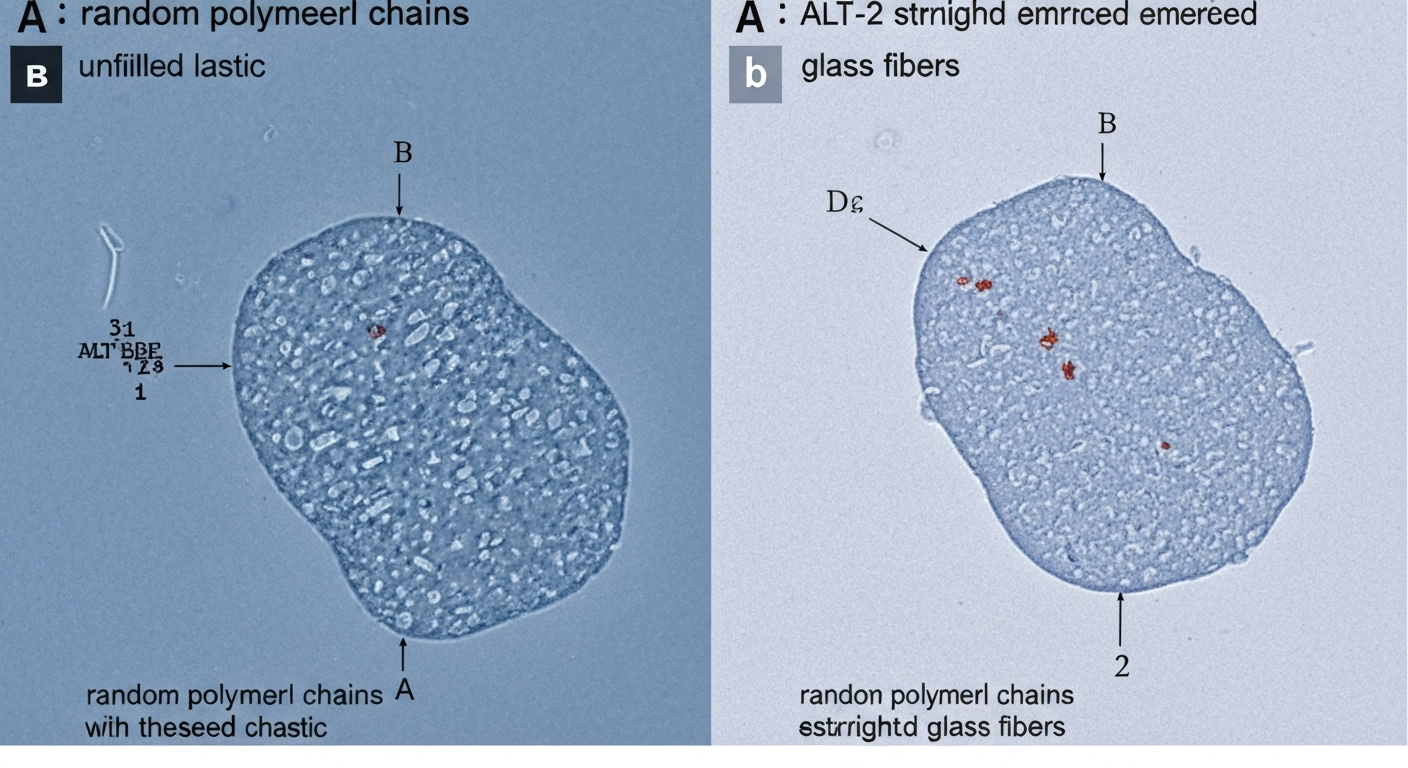

Fillers like glass fiber do not change the plastic's fundamental melting point (Tm), but they dramatically increase its Heat Deflection Temperature (HDT) and stiffness, allowing the part to hold its shape at much higher temperatures.

The Power of Reinforcements

Adding chopped glass fibers or carbon fibers to a thermoplastic is like adding steel rebar to concrete. The plastic resin still melts at the same temperature, but the rigid, internal network of fibers prevents the composite material from bending or sagging until much higher temperatures are reached. A 30% glass-filled Nylon 6/6, for example, can have an HDT of around 250°C, a massive improvement over the 90°C of its unfilled counterpart.

The Role of Impact Modifiers and Plasticizers

Other additives can alter thermal performance. Impact modifiers are rubbery polymers added to improve toughness, but they often slightly lower the HDT. Plasticizers are added to materials like PVC to make them soft and flexible, which significantly lowers their glass transition temperature and heat resistance.

Virgin vs. Regrind Material

In our factory, we often get questions about using "regrind" (recycled material from previous molding runs) to lower costs. While this is a standard practice, it's critical to control the percentage. Too much regrind can lead to a reduction in molecular weight, causing a slight drop in melting point and a more significant reduction in mechanical properties and HDT. For critical applications, we always recommend using 100% virgin material, and this is specified in our PPAP documentation. Need to discuss material options? Contact our engineering team.

How Do We Verify a Plastic's Thermal Properties in Quality Control?

You've signed off on a design based on a material data sheet, but how do you know the plastic pellets that arrive at the factory actually meet that specification? A robust quality control process is essential.

We verify material properties using two key methods: reviewing the Certificate of Analysis (CoA) from the material supplier for every batch, and using lab equipment a like Differential Scanning Calorimeter (DSC) to confirm thermal characteristics like melt point.