How Do You Find a Custom Metal Brackets Manufacturer for Your Industrial Application?

Are off-the-shelf brackets failing to meet your project's specific load requirements or mounting points? Using the wrong hardware compromises structural integrity, leading to costly delays and redesigns.

A true custom metal brackets manufacturer partners with you, using processes like stamping, forming, and CNC machining to turn your design into a precision part. They help you select the right material and finish to ensure it performs perfectly in its intended environment.

I've been in this business for over 30 years, and I can tell you that a simple metal bracket is rarely simple. It's the component that holds everything else together. I once had a client, a major manufacturer of data center equipment, who was using a standard L-bracket that kept failing vibration tests. We worked with them to design a custom-gusseted bracket from a specific steel alloy. It solved their problem completely. That's the difference a dedicated manufacturing partner makes.

What Materials Are Best for Custom Industrial Brackets?

Choosing the wrong metal for your bracket can lead to catastrophic failure from corrosion, fatigue, or overload. Your bracket might look perfect, but will it survive in a marine environment or a high-vibration engine bay?

The best material depends entirely on the application's demands. Stainless steel is ideal for corrosion resistance, carbon steel offers the best strength-to-cost ratio, and aluminum is the top choice when weight is a critical factor.

Stainless Steel for Harsh Environments

When your bracket will be exposed to moisture, chemicals, or salt spray, stainless steel is the only choice. Grades like 304 offer excellent general corrosion resistance, while 316 is the standard for marine and chemical processing applications. It costs more, but the longevity and reliability are worth it, preventing rust from compromising the part's strength.

Carbon Steel for Strength and Value

For most indoor industrial applications where strength and budget are the main drivers, carbon steel is the workhorse. Grades like A36 or 1018 are strong, easy to form and weld, and very economical. They must be coated with paint, powder, or a zinc plating to prevent rust, but they provide unbeatable structural performance for the price. This is a common material for our stamping parts.

Aluminum for Weight-Sensitive Applications

In aerospace, transportation, and electronics, every gram matters. Aluminum offers a fantastic strength-to-weight ratio, is naturally corrosion-resistant, and is non-magnetic. Alloys like 5052 and 6061 are common choices. While it's not as strong as steel, its light weight makes it essential for applications where minimizing mass is a primary design goal.

| Material Feature | Carbon Steel | Stainless Steel | Aluminum |

|---|---|---|---|

| Strength | Excellent | Very Good | Good |

| Corrosion Resistance | Poor (Needs Coating) | Excellent | Very Good |

| Weight | Heavy | Heavy | Lightweight |

| Cost | Low | High | Medium |

| Best For | Structural frames, machine mounts | Food processing, marine, outdoors | Aerospace, electronics, automotive |

Which Manufacturing Process Should Be Used for My Bracket?

You have a design, but how should it be made? Choosing an inefficient process can skyrocket costs for high volumes or make prototyping prohibitively expensive.

The ideal manufacturing process is determined by part complexity, required precision, and production volume. Stamping is best for high volume, CNC machining for complex prototypes, and laser cutting with forming is perfect for versatile, low-to-mid volume production.

Metal Stamping for High-Volume Production

If you need tens of thousands or millions of the same bracket, metal stamping is the most cost-effective method. A progressive die is built to stamp, pierce, and form the bracket from a continuous coil of metal in a single, high-speed operation. The upfront tooling cost is high, but the price per piece is extremely low, and the consistency is unmatched.

Laser Cutting and Forming for Versatility

For prototypes or production runs from a few hundred to a few thousand pieces, this is the go-to process. A high-powered laser cuts the flat pattern of the bracket from a sheet of metal with incredible precision and no tooling cost. The cut blanks are then bent into their final shape on a CNC press brake. This process offers maximum design flexibility and fast turnaround times.

CNC Machining for Precision and Complexity

When a bracket requires complex 3D shapes, threaded holes, or exceptionally tight tolerances that forming cannot achieve, we turn to CNC machining. The part is machined from a solid block of metal. This "subtractive" process is slower and more expensive per part but offers the highest possible precision and is ideal for low-volume, high-performance components.

How Is Precision Ensured in Custom Bracket Manufacturing?

You've sent a detailed drawing with critical tolerances. How can you be sure the parts you receive a month later will actually match that drawing and fit perfectly in your assembly?

Precision is guaranteed through a certified Quality Management System (QMS) like ISO 9001. This system governs every step, from design review and material verification to in-process checks and final inspection with calibrated measurement tools.

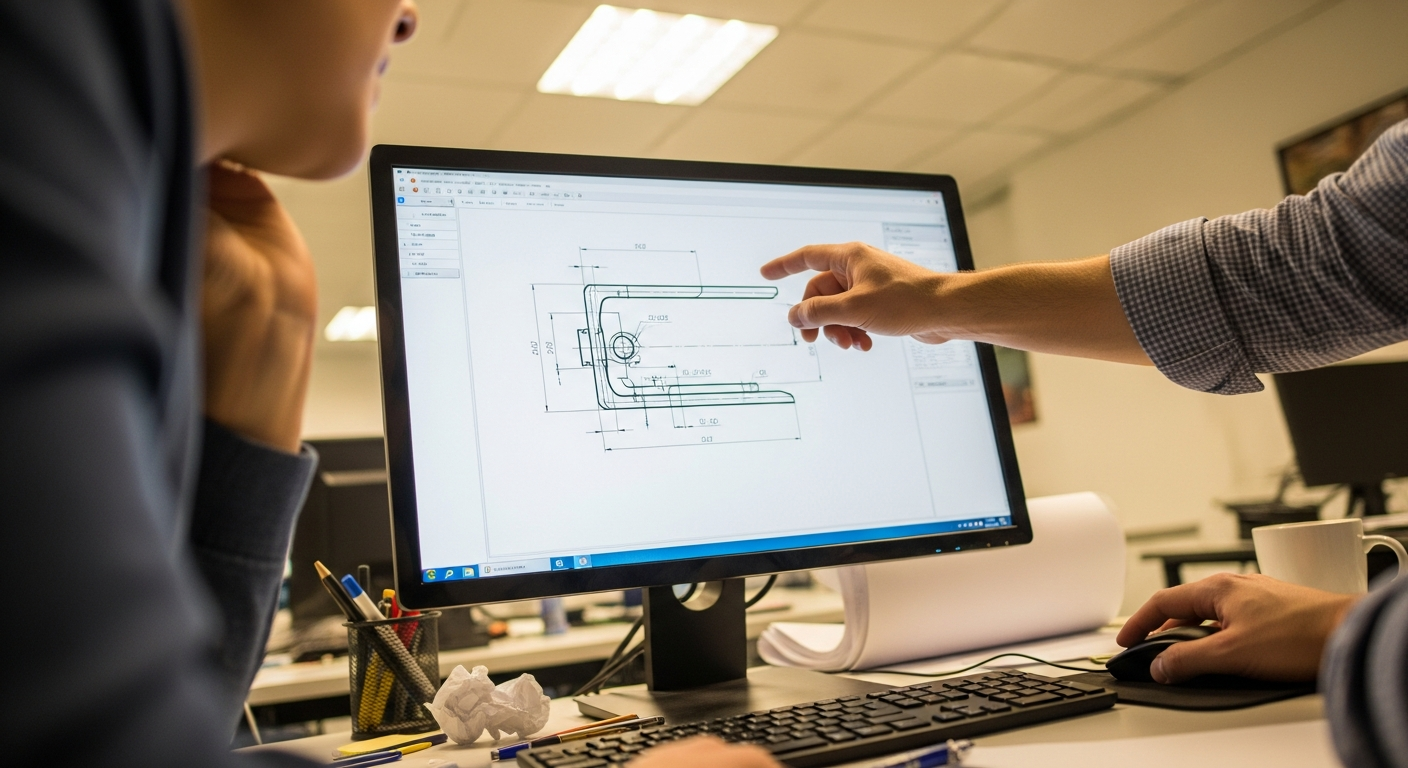

Design for Manufacturability (DFM) Review

Precision starts before we even cut metal. Our engineers review your design to ensure the specified tolerances are achievable with the chosen process. We might suggest a small change to a bend radius or hole location that will make the part more consistent and less expensive to produce, a core part of our collaborative process when preparing a PPAP package.

In-Process Quality Control (IPQC)

We don't wait until the end of the production run to check for quality. Our operators perform regular checks at every stage. For example, during a stamping run, we'll pull a part every 500 hits and check critical dimensions with digital calipers and gauges to ensure the tooling is performing consistently.

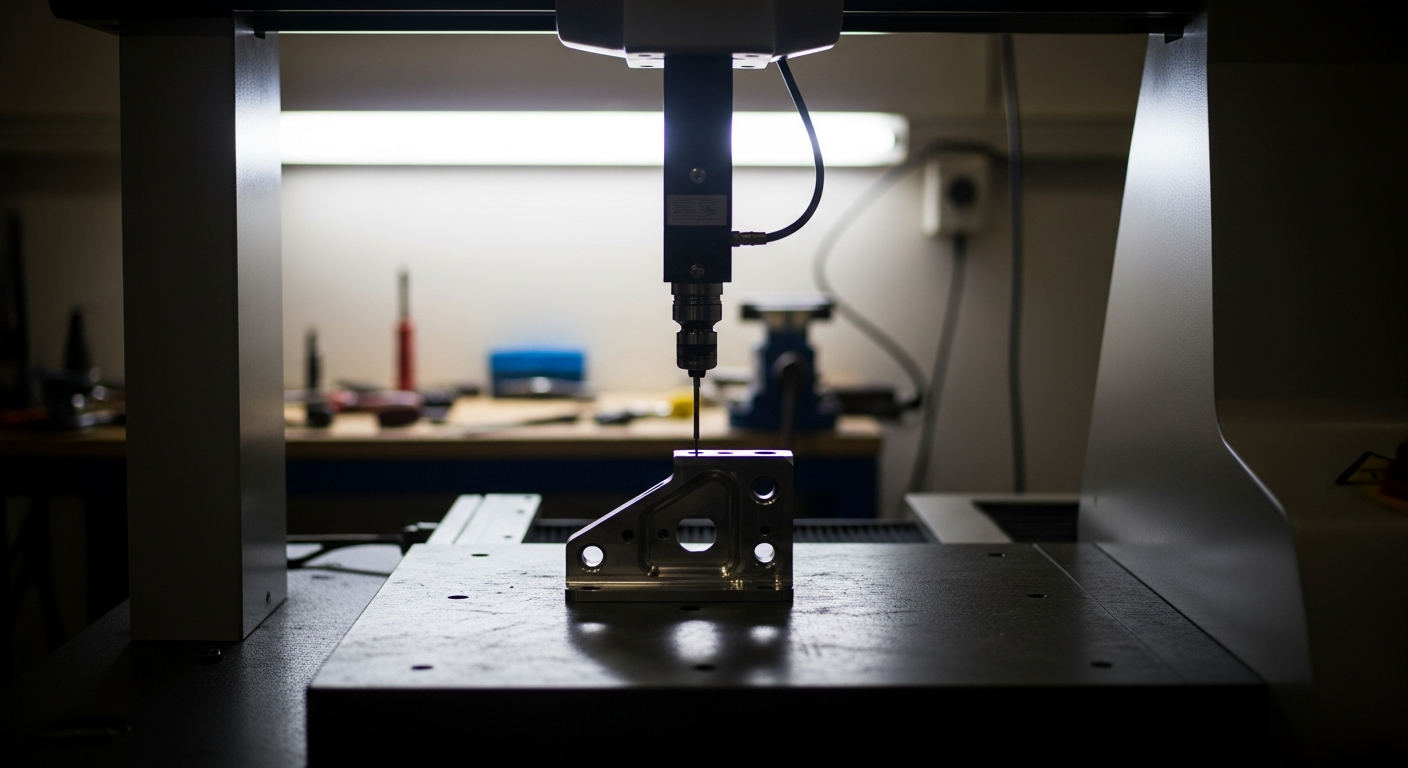

Final Inspection and Documentation

Every batch of parts undergoes a final inspection before shipment. For simple parts, this may involve checking a statistical sample with hand tools. For complex, tight-tolerance parts, we use a Coordinate Measuring Machine (CMM), which uses a robotic probe to measure the part with micron-level accuracy. We provide full inspection reports to give you complete confidence in what you are receiving.

What Finishes and Coatings Are Available for Metal Brackets?

A raw metal bracket is rarely the final product. Without a protective finish, a carbon steel bracket will rust, and an aluminum one can be scratched or stained. The right coating is essential for durability and performance.

The most common finishes are powder coating for a durable, colored finish; zinc plating for cost-effective corrosion protection on steel; and anodizing to create a hard, corrosion-resistant surface on aluminum.

Powder Coating for Durability

Powder coating is an electrostatically applied dry powder that is cured under heat to form a hard, plastic-like skin over the part. It is much more durable and chip-resistant than standard paint and is available in a huge range of colors and textures. This is an excellent choice for brackets that will be visible or subject to wear and tear.

Zinc Plating for Corrosion Protection

This is a standard, cost-effective finish for carbon steel brackets. The part is coated with a thin layer of zinc, which acts as a "sacrificial" barrier. According to industry resources like the American Galvanizers Association, the zinc will corrode first, protecting the steel underneath. It's typically followed by a clear or yellow chromate conversion coating for added protection.

Anodizing for Aluminum Brackets

Anodizing is an electrochemical process that converts the surface of an aluminum part into a durable, corrosion-resistant, and non-conductive oxide layer. The process can be done to create a clear ("natural") finish or can be dyed to produce colors like black, red, or blue. It increases surface hardness and is an excellent primer for paint if needed.

How Do You Get Started with a Custom Bracket Manufacturer?

You're ready to move forward, but what does the process look like? How do you turn your idea into a quote and then into a physical part?

The process is straightforward: submit a Request for Quote (RFQ) with your drawing, collaborate on a DFM review, approve the tooling and a First Article sample, and then authorize mass production. Clear communication is key at every step.

| Step | Action | Our Commitment |

|---|---|---|

| 1. RFQ & Drawing Review | You contact us and submit your CAD file or technical drawing, quantity, and material needs. | We will provide a detailed, itemized quote and initial DFM feedback within 24-48 hours. |

| 2. Tooling & Prototyping | Once the quote is approved, we create any necessary tooling (e.g., a stamping die). | We manufacture tooling in-house to control quality and lead time. |

| 3. First Article Approval | We produce the first parts off the new tool and perform a full inspection (First Article Inspection - FAI). | We send you the FAI report and physical samples for your approval before mass production. |

| 4. Mass Production & Delivery | After your approval, we launch full-scale production, manage quality, and ship the parts to your facility. | We adhere to the agreed-upon delivery schedule and provide quality documentation. |

About the Author

My name is Kevin. I started my career in the US buying industrial parts, so I know the challenges of sourcing firsthand. In 1993, I founded Prime Metals in China to build a factory that does things differently—focusing on engineering, transparent communication, and a robust ISO 9001 quality system. We don't just make parts; we build partnerships that result in reliable, high-quality hardware.

Frequently Asked Questions (FAQs)

What information is needed for an accurate quote on custom brackets?

To give you the best price, we need a technical drawing or 3D CAD model, the material type (e.g., Steel A36, Aluminum 6061), the required quantity, the desired finish (e.g., powder coat black), and any critical tolerances.

What is the typical lead time for custom metal brackets?

Lead time depends on the process. For parts made with laser cutting and forming (no tooling), we can often deliver in 2-4 weeks. For stamped parts that require a new progressive die, the tooling can take 4-8 weeks, with production following immediately after sample approval.

Can you help with the design of a metal bracket?

While we are not a design firm, our Design for Manufacturability (DFM) review is a core part of our service. Our engineers will analyze your design and provide expert feedback to improve its strength, lower its cost, and ensure it can be manufactured consistently.

A Partner in Precision

A custom metal bracket is more than a piece of bent metal—it's a critical component engineered for a specific purpose. Choosing a manufacturer who understands materials, processes, and quality is the foundation of a successful product.

Let our experience work for you. Let's build something great together.