Breaking Strength vs. Working Load Limit: What's the Real Difference for Industrial Components?

You’re reading a spec sheet for a critical fastener, and it lists a “breaking strength” of 10,000 pounds. You might think, “Perfect — my application only needs 8,000 pounds.” That assumption can cause catastrophic failure.

Breaking strength measures the maximum force a component withstands in a lab before it fails. It does not represent a safe working load. The safe load, or Working Load Limit (WLL), divides the breaking strength by a safety factor to reflect real-world conditions.

In my three decades in the hardware industry, I’ve seen confusion between these two numbers cause the most dangerous failures. One client once used lifting eye bolts near their listed breaking strength. A single jolt caused them to snap. After switching to parts rated for the correct Working Load Limit, the issue disappeared. Understanding this difference saves money—and lives.

What Exactly Is Breaking Strength?

It’s an impressive number on a spec sheet—but what does it actually mean?

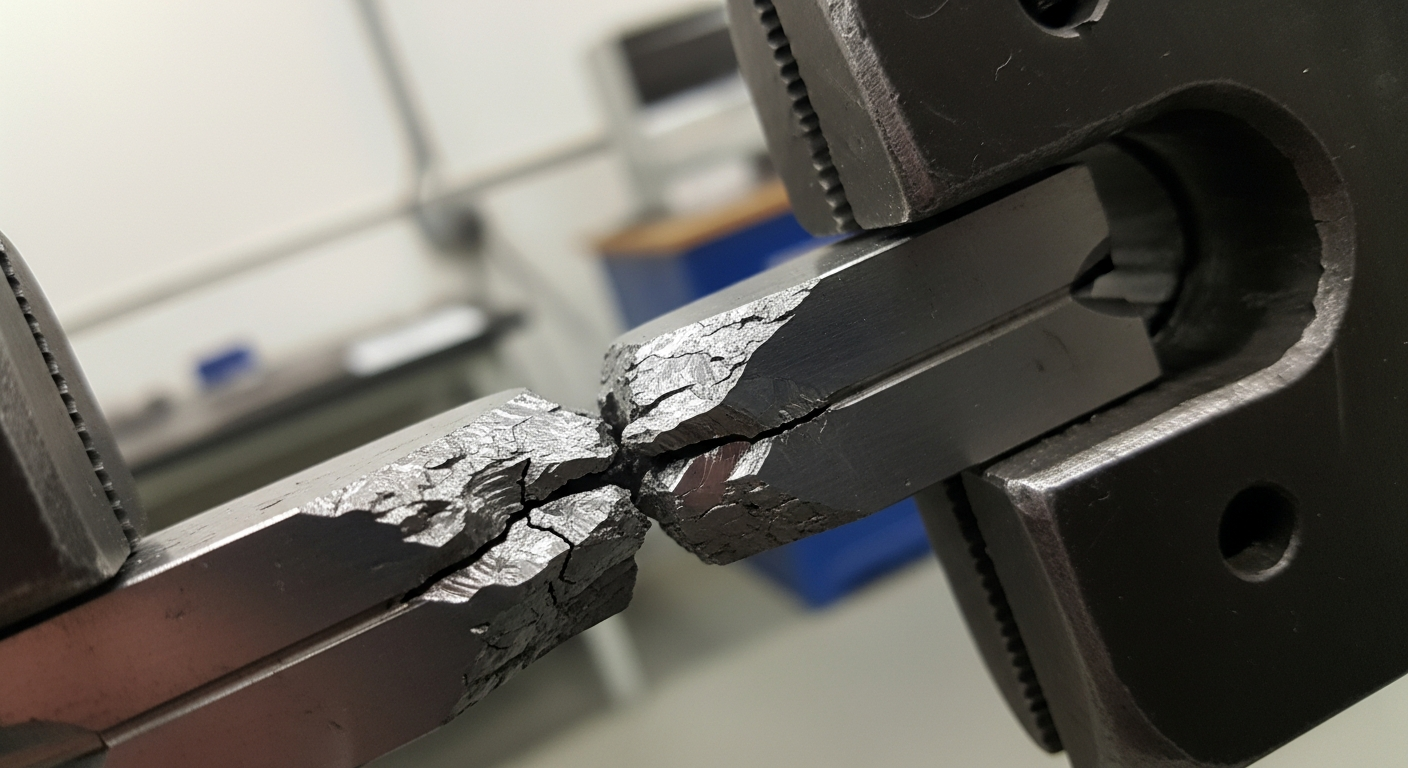

Breaking strength, or Ultimate Tensile Strength (UTS), represents the highest force a sample can endure before fracturing. Testers determine it by pulling a part apart under controlled conditions.

The Point of No Return

A tensile test destroys the part. It reveals the material’s upper limit under perfect lab conditions—but not how it behaves in service. Think of it as a car’s top track speed, not the speed for daily driving.

Different Types of Forces

Parts face multiple kinds of stress:

- Tensile Strength: Pulling force that separates the material.

- Compressive Strength: Crushing force that shortens the material.

- Shear Strength: Cutting force across the material’s plane.

In industrial hardware—fasteners, brackets, chains—tensile strength usually matters most.

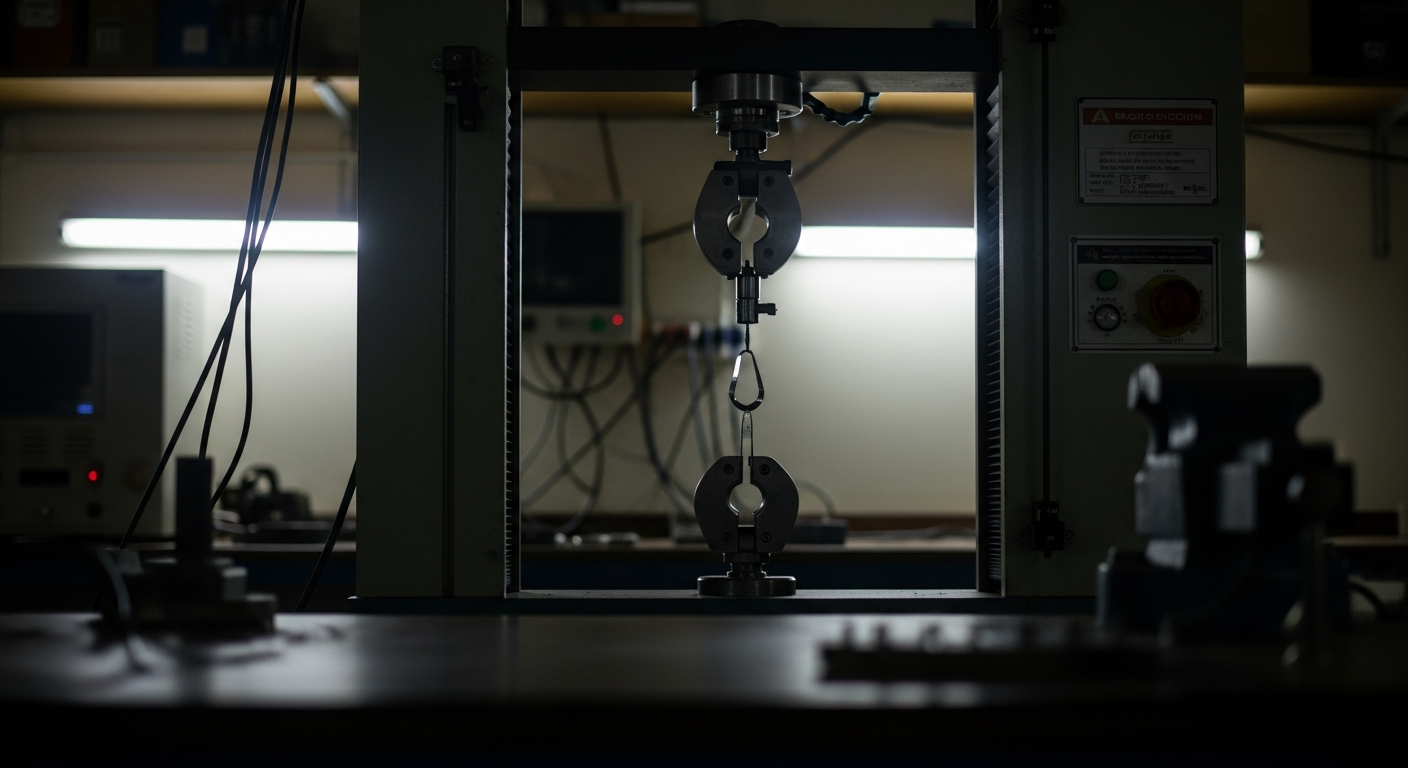

How We Measure It in Our Factory

Our factory verifies raw materials and finished parts like custom screws using a tensile testing machine. We clamp a sample, apply a controlled load, and record force versus elongation. This produces precise data on strength and ductility, which we include in PPAP documentation.

Why Can’t You Use Breaking Strength as the Safe Load?

If a part breaks at 10,000 pounds, why not use it at 9,000?

Because the real world is unpredictable.

Engineers apply a “safety factor” to reduce the breaking strength and determine the safe limit—the Working Load Limit (WLL).

Understanding the Safety Factor

A safety factor (3:1 to 10:1) builds a buffer between test conditions and real-world risks. General hardware often uses 4:1 or 5:1, while lifting or human-support systems may require 10:1 or higher.

Real-World Variables Covered by the Safety Factor

- Shock Loading: Sudden jerks multiply load forces.

- Wear and Fatigue: Repetition and vibration weaken parts over time.

- Environmental Factors: Temperature swings and corrosion degrade metal strength.

- Material Flaws: Even microscopic defects can start cracks.

Calculating the Working Load Limit

Working Load Limit = Breaking Strength ÷ Safety Factor

Example:

10,000 lbs ÷ 5 = 2,000 lbs.

That means you must never exceed 2,000 lbs in service.

How Do Material and Manufacturing Influence Strength?

A part’s listed strength results from both its material and how you make it.

The alloy’s intrinsic properties and the manufacturing method determine its ultimate performance.

Material Selection

Different metals produce different strength levels—critical in our stamping parts and CNC parts.

| Material | Typical Tensile Strength (PSI) | Characteristics |

|---|---|---|

| Low Carbon Steel (A36) | 58,000–80,000 | Economical, easy to weld. |

| Alloy Steel (4140) | ~95,000 (annealed) | Strong, tough, heat-treatable. |

| Stainless Steel (304) | ~85,000 | Corrosion-resistant, durable. |

| Aluminum (6061-T6) | ~45,000 | Lightweight, good corrosion resistance. |

Heat Treatment Boosts Performance

We strengthen steels through controlled heating and quenching, transforming their internal structure. That’s how a Grade 5 bolt far outperforms a basic Grade 2.

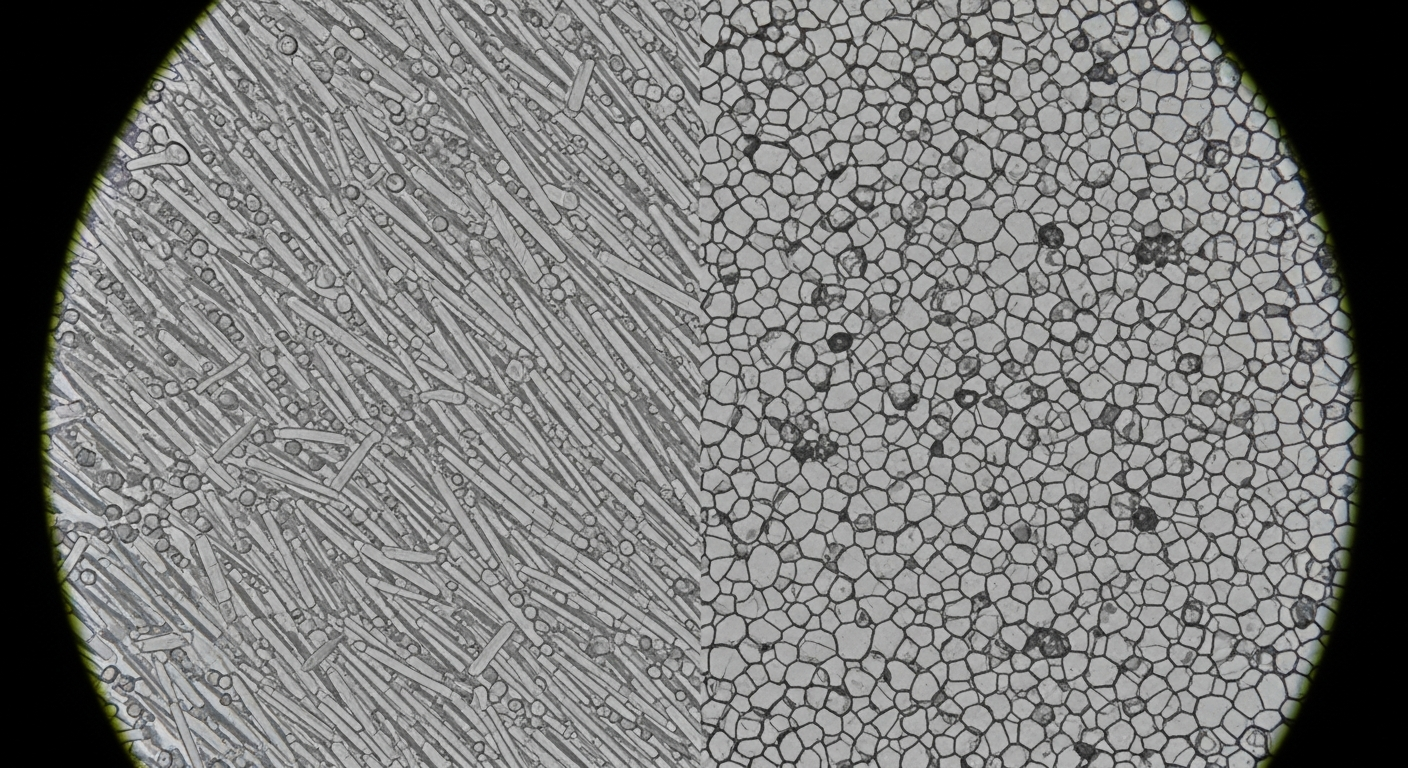

Manufacturing Matters

Forging compresses and aligns metal grains along the part’s shape, producing exceptional fatigue resistance.

Casting creates random grain structures and potential porosity, making it weaker. That’s why high-stress parts like engine rods are always forged, not cast.

How to Verify a Supplier’s Strength Claims

When a supplier lists a breaking strength, how can you trust it?

Look for certification, traceability, and testing documentation under ISO 9001.

Request Material Test Reports (MTRs)

An MTR links each batch to the producing mill and includes chemistry and mechanical results like tensile strength. We always provide MTRs for critical components.

Use the PPAP System

Through PPAP, we validate every production step with data and destructive tests to confirm consistent strength across batches.

Continue Destructive Testing During Production

We regularly pull samples and retest strength to verify that our welding, heat treatment, and forming processes stay within specification.

Common Buyer Mistakes About Strength

The biggest mistake? Designing to breaking strength instead of WLL.

The second: ignoring how temperature, corrosion, and assembly design reduce real-world capacity.

Overlooking the Weakest Link

A high-strength bolt won’t help if the bracket it connects to is weaker. Always evaluate the strength of the whole system. We design and supply complete hardware assemblies to ensure balance.

Ignoring Temperature Effects

Cold makes steel brittle; heat causes creep. Always select materials rated for your operating range.

Neglecting Corrosion

Rust removes metal, reducing cross-section and load capacity. For outdoor or chemical exposure, use stainless steel or apply protective coatings.

About the Author

I’m Kevin, founder of Prime Metals. I started this company in 1993 after years sourcing industrial components in the U.S. I saw how poor engineering caused failures, so I built Prime on a simple belief: understand the science, control the process, and deliver reliability. Our ISO 9001 certification represents our starting point, not our finish line.

Frequently Asked Questions (FAQs)

What’s a typical safety factor for industrial hardware?

For general hardware: 4:1–6:1.

For lifting or human support: 10:1+, per OSHA and similar standards.

Is breaking strength the same as tensile strength?

They’re closely related. Ultimate Tensile Strength (UTS) defines the peak stress before fracture; breaking strength is the force at fracture. For buyers, both indicate the failure threshold.

How do holes or notches affect strength?

Sharp edges concentrate stress, reducing breaking strength. We prevent this by adding radii and conducting DFM reviews before production.

Strength Is a System — Not Just a Number

Breaking strength gives you a lab number; Working Load Limit gives you a safe reality.

True reliability comes from understanding both and partnering with a manufacturer who verifies every batch.

Let’s engineer hardware that performs safely and consistently.