CNC Machining Services in China for Small Batches (5–200 pcs): A Price & Lead Time Guide?

leading paragraph: Are you being ignored by large factories for your small-batch orders? This stops your product development and delays your market entry. We specialize in low-volume manufacturing.

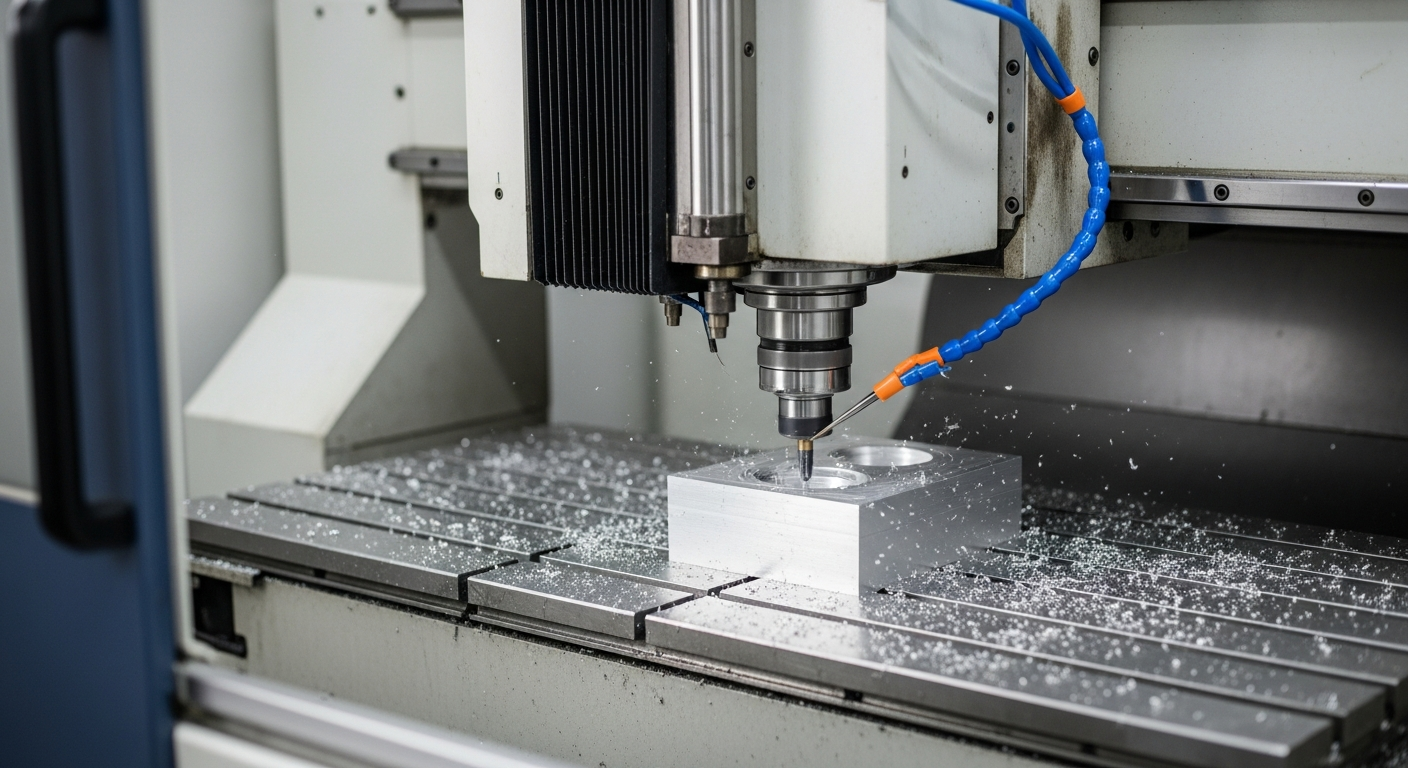

snippet paragraph: Yes, small-batch CNC machining in China is very cost-effective. For a batch of 5–200 pieces, prices are driven by setup time, material, and complexity. Lead times are typically 1-2 weeks for prototypes and faster for repeat orders. We make low-volume production simple and affordable.

Transition Paragraph: Many buyers think that factories in China only want huge orders. But for many projects, you don't need thousands of parts. You need a small batch for testing, for a niche product, or to get to market fast. The key is finding the right low-volume CNC machining supplier. We have built our business to support these exact needs. Let's look at how it all works.

LOOP START

When does Small-Batch CNC Machining in China Make Sense?

leading paragraph: Are you developing a new product but afraid of the high cost of full production? Committing to a large order too early is a huge financial risk if the design isn't perfect.

snippet paragraph: Small-batch CNC machining makes perfect sense for prototypes, market testing, and bridge production. It allows you to get high-quality, functional parts in your hands quickly without the massive upfront cost and commitment of mass production tooling. It's flexible and fast.

Dive deeper Paragraph: Using a low-volume CNC machining supplier is a smart business move in several situations. I remember my client Kevin from the U.S. needed to test a new electronics enclosure. He wasn't ready to invest in an injection mold, which costs thousands. Instead, we machined 50 units for him. This allowed him to test the fit and function with real customers before committing to a larger order.

Key Applications for Small Batches

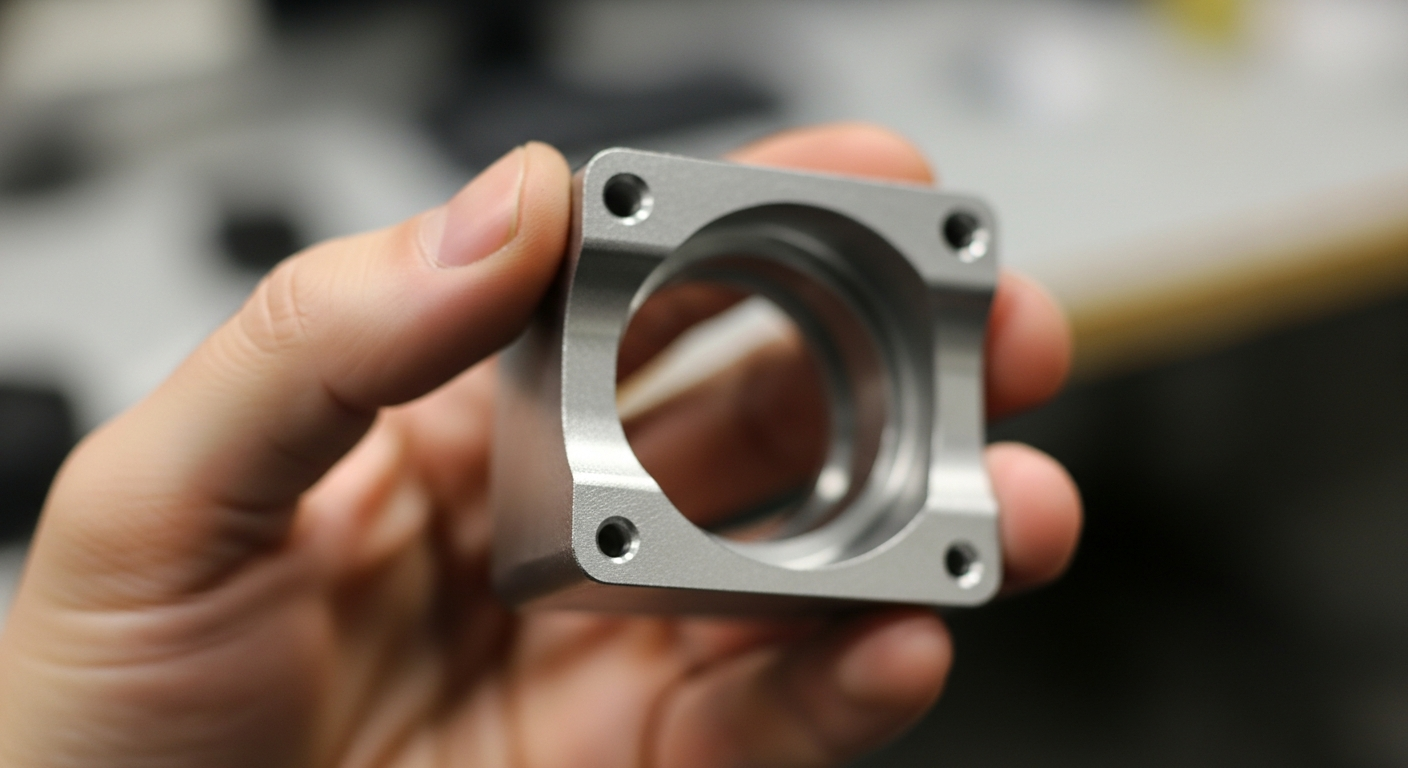

- Prototyping: When you need a functional prototype that looks and feels like the final product, CNC prototype machining in China is the best choice. It's much stronger and more accurate than 3D printing for many applications.

- Bridge Production: This is when you have a production gap to fill. Maybe you are waiting for your high-volume tooling to be finished. A small batch of 200 machined parts can keep your sales going.

- Market Testing: Launch your product to a small group of customers to get feedback before scaling up.

LOOP END LOOP START

What are the Typical Price Drivers for 5–200 pc Orders?

leading paragraph: Confused why one quote for a small batch is double the price of another? Unexpected costs can ruin your budget and make planning impossible. We make pricing clear.

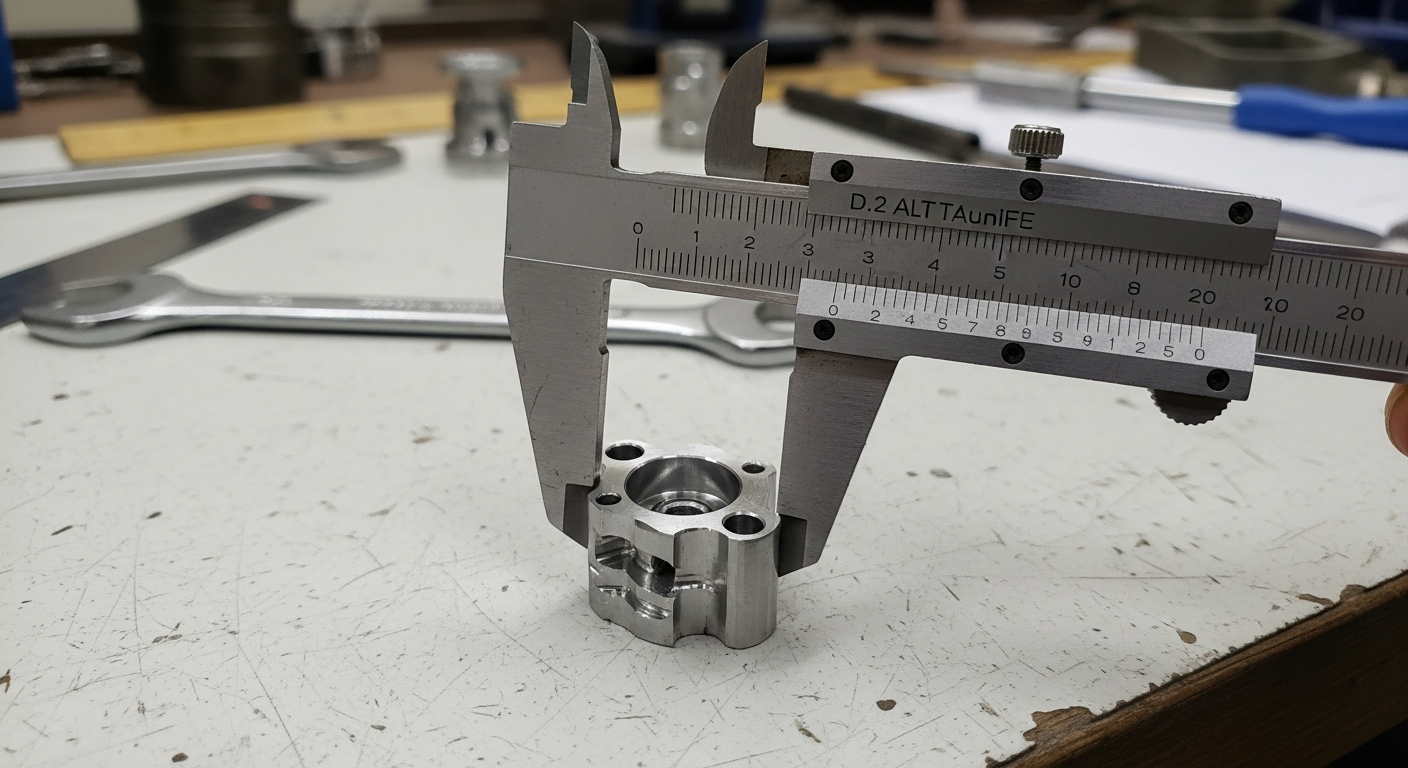

snippet paragraph: For small CNC batches, the main price drivers are machine setup time, raw material cost, part complexity, and required tolerances. The "per-piece" price is higher than mass production because the initial setup costs are spread over fewer parts.

Dive deeper Paragraph: Understanding the costs helps you design parts that are more economical to manufacture, especially in low volumes. Since setup time is a major factor, the more parts you can make in one setup, the lower the per-piece cost becomes. This is the core principle of manufacturing economy of scale. Even going from 20 pieces to 80 pieces can significantly reduce the price for each part. I always explain this to my customers so they can make the best decision for their budget. For example, a simple aluminum block will be much cheaper than a complex part with many curved surfaces and tight-tolerance holes.

Here is a simple breakdown of the cost drivers for small-batch CNC machining.

| Price Driver | Description | Impact on Cost (5-200 pcs) |

|---|---|---|

| Setup Time | Time to program the CNC machine, load tools, and fix the material. A one-time cost per batch. | High |

| Material Cost | The price of the raw material block (e.g., Aluminum 6061 vs. Stainless Steel 316). | Medium to High |

| Part Complexity | How many machine operations and tool changes are needed. Simple parts are faster. | Medium |

| Tolerances | Tighter tolerances require more precise machining and inspection, which takes more time. | Medium |

LOOP END LOOP START

What is the Lead Time for Samples vs. Repeat Small Batches?

leading paragraph: Do you need your parts fast but worry about long, unpredictable lead times from overseas suppliers? Delays can cause you to miss important deadlines and sales opportunities.

snippet paragraph: For a new small-batch CNC project, the lead time is typically 1-2 weeks. This includes programming and setup. For a repeat order of the same part, the lead time is often just 3-5 business days because the programming and setup files are already saved.

Dive deeper Paragraph: Speed is one of the biggest advantages of small-batch CNC machining. When Kevin needed his first 50 prototype enclosures, we delivered them to him in about 10 days. The initial order always takes a bit longer. Our engineers had to analyze his 3D model, create the machine toolpaths (CAM programming), set up the CNC machine with the right tools, and run the first part for inspection. This process ensures quality for the entire batch. However, when he came back two months later and needed another 80 units with a minor change, the process was much faster. We already had the main program ready. We just needed to make a small adjustment and run the parts. That repeat order was finished and shipped in less than a week. As a reliable low-volume CNC machining supplier, we keep all customer files ready for fast repeat orders. This helps our clients move quickly from prototype to production.

LOOP END LOOP START

Can You Show Examples of Small CNC Projects? (20, 80, 200 pcs)

leading paragraph: Are you struggling to find a supplier with real experience in your specific order size? Seeing past projects provides confidence that a factory can handle your needs effectively.

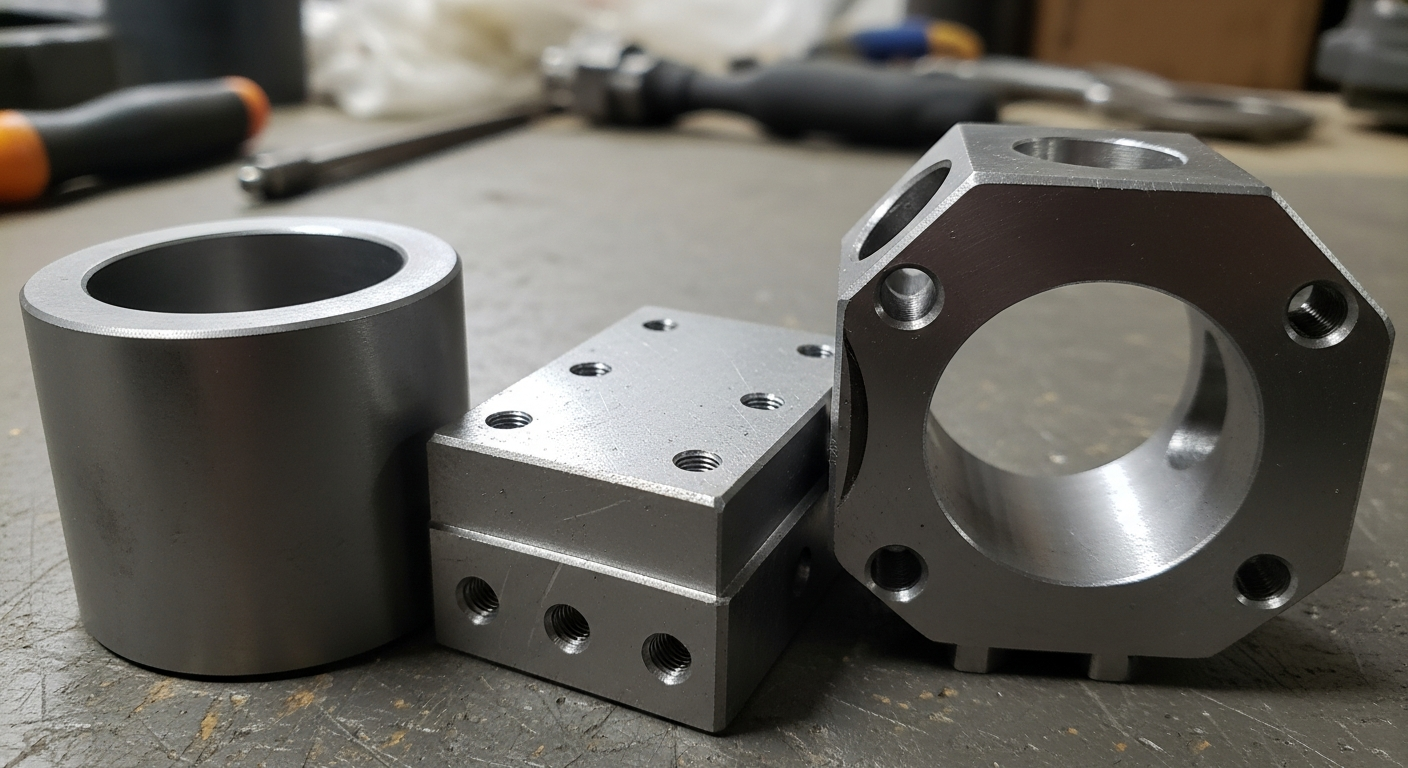

snippet paragraph: Certainly. We recently completed a 20-piece order for custom aluminum heatsinks, an 80-piece batch of stainless steel mounting brackets for a robotics company, and a 200-piece pre-production run of Delrin plastic gears for a new consumer product.

Dive deeper Paragraph: Real-world examples show our flexibility as a low-volume CNC machining supplier in China. Every small-batch project has a different goal. Some are for testing, some are for a first production run, and some are for highly custom, niche equipment that will never be mass-produced. We treat every order with the same high level of attention, whether it's for 5 pieces or 200. I worked closely with a European client on a project for custom lab equipment. They only needed 20 units in total. Many factories would not even quote this. But for us, it was a perfect project. We delivered high-quality parts that met their very specific requirements.

Here are a few recent examples of our small-batch CNC machining work:

| Batch Size | Part Description | Material | Project Goal |

|---|---|---|---|

| 20 pcs | Custom Heatsinks | Aluminum 6061-T6 | Functional prototype testing |

| 80 pcs | Mounting Brackets | Stainless Steel 304 | First production batch for a new robot |

| 200 pcs | Small Gears | Delrin (POM) | Pre-production run for market validation |

LOOP END LOOP START

How Do You Get a Fast, Accurate Small-Batch Quote?

leading paragraph: Tired of sending emails and getting no reply for your small-batch inquiries? Your time is valuable, and waiting for quotes is frustrating. You can get a quote from us quickly.

snippet paragraph: To get a fast quote for your CNC machining small batch in China, send us a complete RFQ. Include your 3D CAD file (STP/IGS), a 2D drawing with tolerances (PDF), the material, the quantity needed (e.g., 50 pcs), and the required surface finish.

Dive deeper Paragraph: The secret to a fast quote is a good request. When you provide all the information upfront, our engineers don't have to guess or send emails asking for details. We can calculate the price right away. This is why we prioritize complete RFQs. My most efficient projects start with a great RFQ. It shows that the buyer is professional and serious about the project. For your small-batch CNC machining project, a perfect RFQ package includes:

- 3D Model: The file we use to create the machine program. STP or IGS files work best.

- 2D Drawing: The file that shows critical dimensions, tolerances, threads, and surface finish requirements. A PDF is perfect.

- Material: Be specific. "Aluminum" is not enough. "Aluminum 6061-T6" is what we need.

- Quantity: Tell us exactly how many you need. Ask for price breaks (e.g., 50, 100, 200 pcs) if you are flexible.

- Finish: Do you need it anodized, sandblasted, or as-machined? Let us know.

Ready to start? Send us your drawings.

LOOP END

Conclusion

Small-batch CNC machining in China offers the ideal balance of speed, precision, and cost for prototypes and low-volume production.

And when paired with a proven factory, the process becomes even smoother.

If you’re ready to move from research to real parts, explore our full CNC machining capabilities here:

👉 Prime Metals – Custom CNC Parts & Machining Services

With the right supplier, you get dependable quality, fast turnaround, and competitive pricing—no matter the batch size.