Quality Control System

Someone Standard of Quality Called Prime

Through rigorous testing and certified processes, we ensure every product meets the highest industry standards

Since its founding in 1993, Prime has treated quality as the cornerstone of its success. Guided by the ISO international quality management system, we maintain strict control at every stage—from raw material sourcing and processing to final product testing—ensuring that each component consistently meets or exceeds global standards.

Equipped with advanced testing instruments and supported by an experienced inspection team, we ensure stable product performance and precise dimensions, delivering safe and reliable industrial hardware solutions to our customers.

AQL – Shipment-Level Quality Assurance

At Prime, outgoing inspections are governed by AQL (Acceptable Quality Limit) standards. This statistical approach ensures that each shipment meets the agreed acceptance level for minor, major, and critical defects. By applying defined sampling plans, we minimize risk while balancing inspection efficiency and customer requirements. Every lot is checked for dimensional accuracy, surface finish, and mechanical performance, supported by documented records and traceability to material heat numbers and production batches. This guarantees that customers receive parts that are safe, reliable, and consistent across every delivery.

PPAP – Production Validation & Compliance

For industries requiring advanced qualification, we deliver full PPAP (Production Part Approval Process) documentation, aligned with IATF 16949 compliance. Our PPAP reports cover design records, engineering change notes, process flow diagrams, control plans, MSA, dimensional inspection results, and material/functional test data. The submission is finalized with a Part Submission Warrant (PSW), providing proof that mass production processes are capable, stable, and repeatable. This structured validation framework ensures not only product quality but also long-term supply reliability—building confidence that Prime can support global OEM programs with consistent standards and audit-ready documentation.

Incoming Material refers to raw materials, components, or semi-finished products received from suppliers that will be used in a manufacturing or production process.

Prior to acceptance, all incoming materials undergo rigorous documentation review, including validation of material test certificates (MTC), chemical composition reports, and compliance certificates (e.g., RoHS, REACH), while simultaneously ensuring full batch traceability through unique lot numbering, supplier data recording, and digital archiving for minimum 10-year retrievability.

Each material batch is subjected to dimensional verification using calibrated instruments (micrometers, CMMs) against engineering drawings, complemented by surface defect detection through visual examination under standardized lighting and microscopic analysis for critical applications, with all deviations documented in the non-conformance system.

Representative samples from every shipment are analyzed via XRF spectroscopy for elemental composition and tested for mechanical properties (hardness, tensile strength) using accredited laboratory equipment, with comparative results against both supplier specifications and internal quality benchmarks, followed by escalation protocols for out-of-tolerance findings.

Materials are inspected per statistically valid AQL sampling plans (MIL-STD-105E Level II for standard items, 100% inspection for high-risk components), then stored under controlled environmental conditions (temperature/humidity monitoring for sensitive materials) with FIFO inventory rotation and periodic shelf-life audits to prevent degradation before production use.

In-Process Control (IPC) refers to the systematic monitoring and inspection of products during the manufacturing process—before final completion—to ensure quality standards are met at every production stage.

In-Process Control involves continuous real-time monitoring of production parameters (temperature, pressure, speed, etc.) using calibrated sensors and SPC (Statistical Process Control) systems to immediately detect deviations from predefined tolerances, while automatically logging data for traceability and trend analysis to prevent non-conformities before defective products are generated.

At predetermined critical control points throughout the manufacturing sequence, IPC requires technicians to perform dimensional inspections using precision instruments (CMMs, optical comparators), material property tests (hardness gauges, XRF analyzers), and functional checks (leak tests, electrical continuity) with documented results compared against engineering specifications to ensure interim product conformity before subsequent processing.

When IPC identifies out-of-spec conditions, it triggers immediate corrective protocols including machine recalibration, tool replacement, or process adjustment by authorized personnel, accompanied by quarantine of affected work-in-progress and root cause analysis through methodologies like 5Why or Fishbone diagrams to implement permanent solutions rather than temporary fixes.

IPC mandates systematic recording of all inspection data (measurements, test results, operator signatures) through electronic batch records or paper-based travelers that move with the product through each workstation, ensuring full process traceability for quality audits and providing legal evidence of compliance with industry regulations such as ISO 9001 or FDA 21 CFR Part 820 for medical devices.

Final Inspection is the last comprehensive quality control check performed on finished products before shipment, ensuring they meet all specified requirements (dimensional, functional, cosmetic, and safety standards). It serves as the final “gate” to prevent defective items from reaching customers.

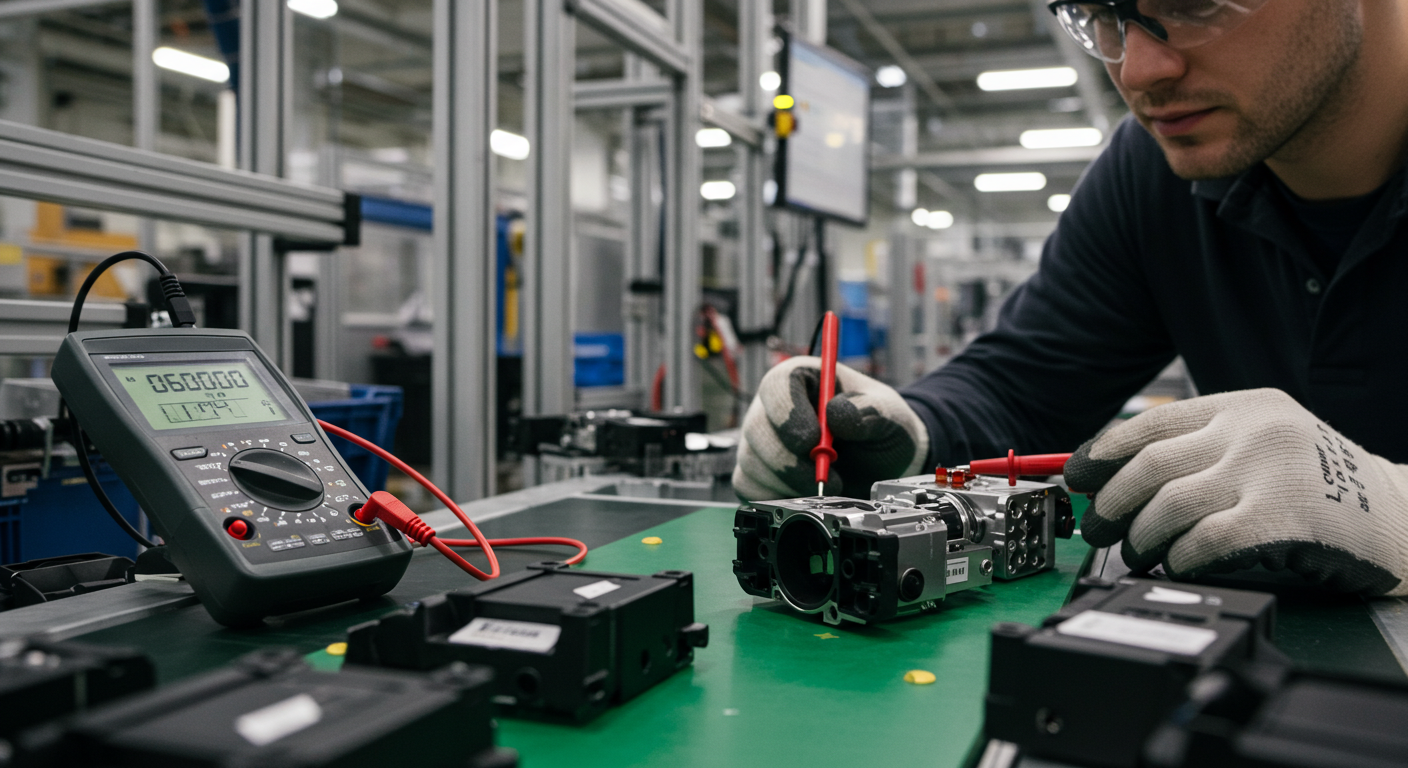

Final inspection involves rigorous testing against all product requirements documented in engineering drawings, customer contracts, and industry regulations (such as ISO 9001 or ANSI standards), covering critical dimensions, material properties, surface finishes, labeling accuracy, and functional performance through calibrated instruments (e.g., CMMs for geometry, multimeters for electronics, torque testers for assemblies) to certify compliance before release.

For batch production, statistical sampling plans like ANSI/ASQ Z1.4 (AQL levels) are applied to inspect a representative subset of units, where defects are categorized into major (safety/functional risks), minor (cosmetic issues), and critical (life-threatening flaws), with predetermined acceptance/rejection thresholds triggering corrective actions such as 100% sorting or production halt if limits are exceeded.

Every inspected product must have complete records, including inspection reports, serial numbers, test certificates, and compliance declarations (e.g., CE/FCC marks), stored digitally or physically for traceability, while non-conforming items are segregated into quarantine zones with detailed discrepancy reports to initiate root cause analysis (RCA) and prevent recurrence in future batches.

The inspection extends to verifying packaging integrity (drop tests, humidity resistance), correct labeling (barcodes, hazard symbols), and proper documentation (commercial invoices, material safety data sheets) to ensure products survive transit and meet import/export regulations, with random audits performed on loaded containers to confirm no damage occurred during staging.

A Shipment Audit is the final quality verification performed on packaged goods immediately before dispatch

The audit involves physically matching the shipped items against the packing list and purchase order (PO) details, including SKU numbers, batch/lot codes, serial numbers, and quantities, using barcode scanners or RFID systems to ensure zero discrepancies, with automated alerts triggered for mismatches to halt incorrect shipments before they leave the facility.

Every shipment undergoes validation of packaging materials (e.g., moisture-resistant barriers for sensitive goods), cushioning adequacy (drop-test certification for fragile items), and regulatory markings (hazard labels for dangerous goods, CE/FCC symbols for electronics), supported by documented photos or checklists to prove compliance with international standards like ISTA for transit durability or IATA for air freight safety.

Critical shipping documents—commercial invoices, certificates of analysis (CoA), material safety data sheets (MSDS), and customs declarations—are audited for data consistency (weights, harmonized tariff codes), legal compliance (INCOTERMS, export licenses), and customer-specific requirements (e.g., retail compliance tags), with digital archiving for at least 5–7 years to support potential audits or disputes.

The audit extends to inspecting container/pallet loading patterns (weight distribution, strapping tension) and vehicle conditions (temperature logs for perishables, GPS seals for high-security cargo), often using IoT sensors to monitor real-time shocks/tilts during transit, with corrective actions like repacking or carrier replacement initiated if risks are identified.

Testing Methods & Equipment

Coating Thickness Measurement | XRF Analyzer

A non-destructive testing method that uses X-ray fluorescence to accurately measure the thickness and composition of coatings or platings on materials.

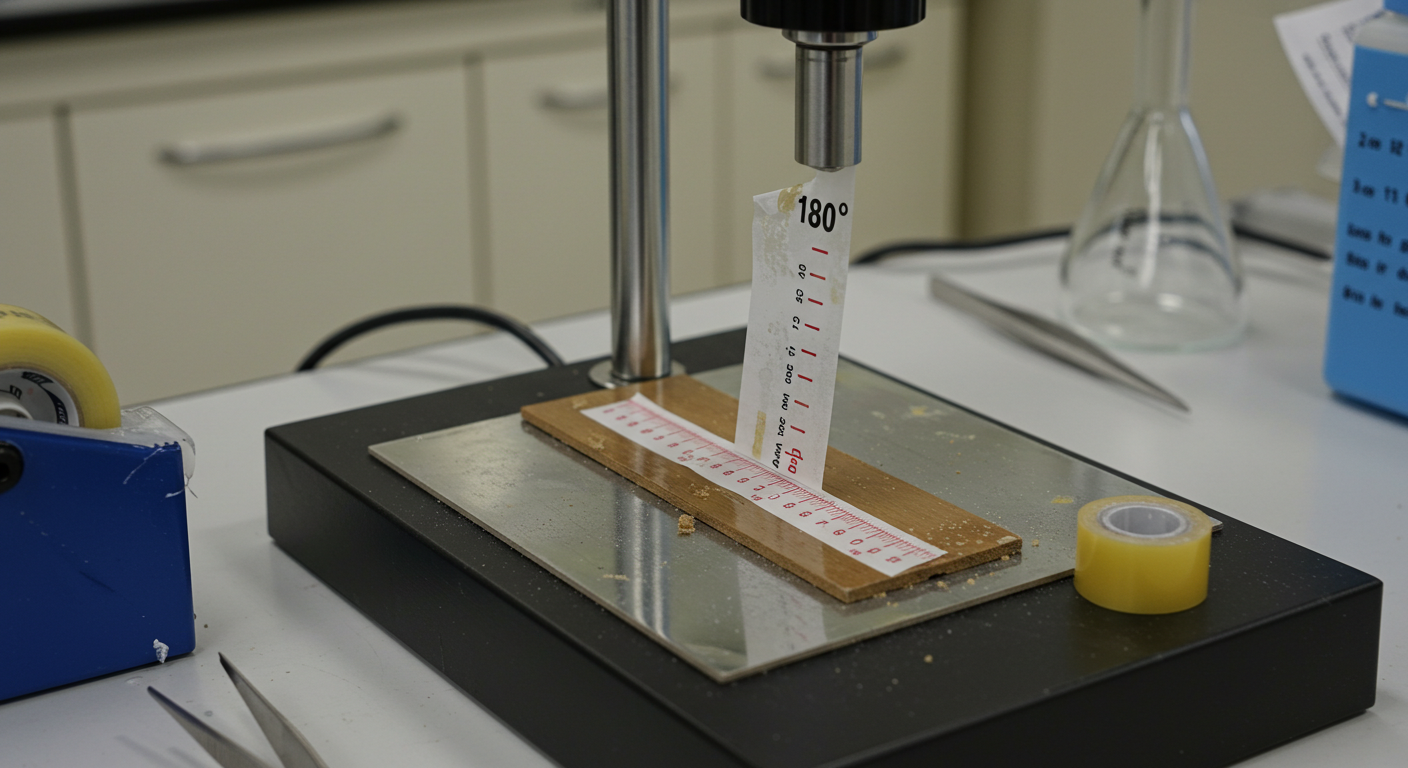

Adhesion Test | ASTM D3359

A standardized method to evaluate coating adhesion to substrates using either cross-cut tape (Method B) or X-cut tape (Method A) to assess resistance to peeling.

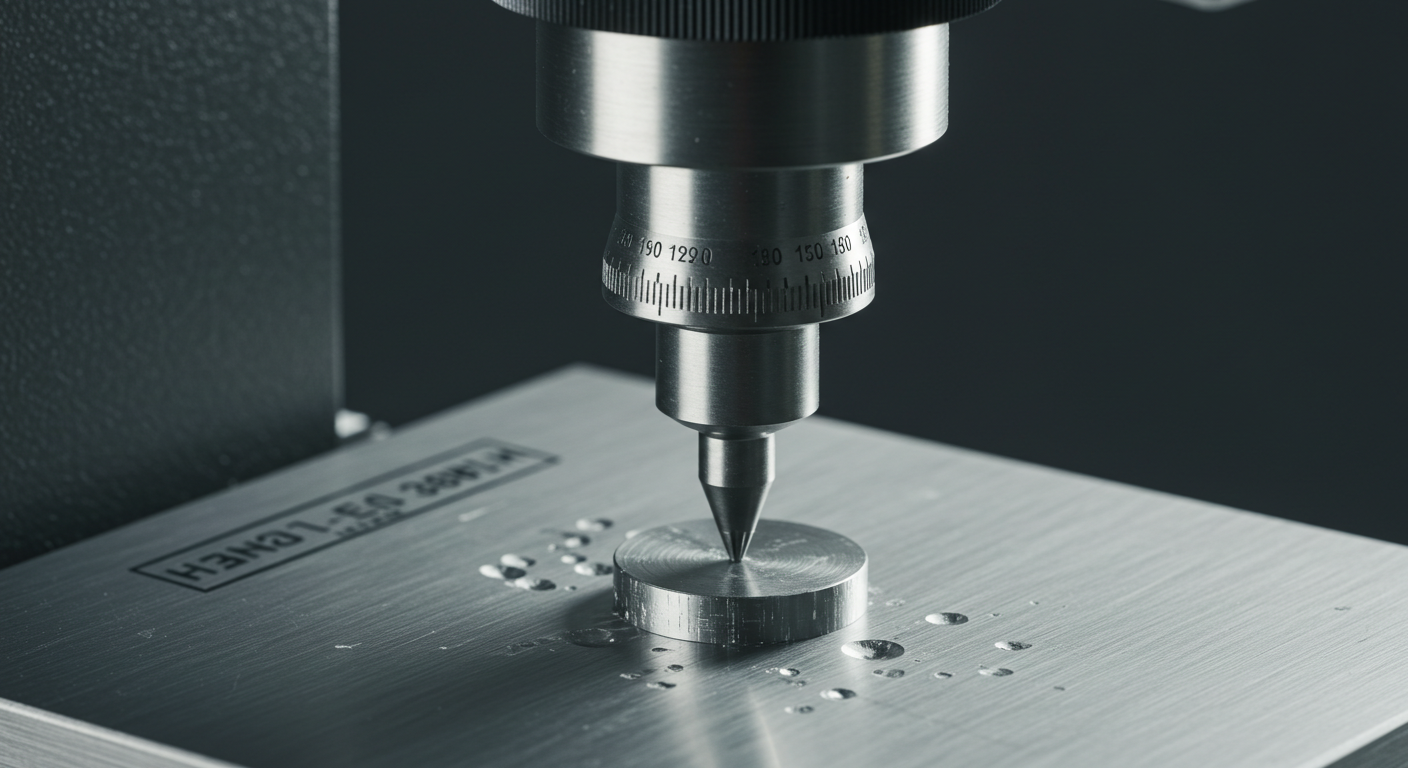

Hardness Test | Rockwell Scale

A quick, precise method to measure material hardness by indentation depth under specific loads, with results displayed as Rockwell hardness numbers (e.g., HRC, HRB).

Salt Spray Test | ASTM B117

A standardized corrosion resistance evaluation that exposes materials to a controlled saline mist environment to simulate accelerated weathering.

Our Quality Certifications

1. ISO 9001:2015 (Quality Management Systems)

Core Focus: Process approach with risk-based thinking

Key Requirements:

Context analysis (Clause 4)Benefits: Improves operational efficiency and customer satisfaction

2. ISO 13485 (Medical Devices – QMS)

Special Requirements:

Stricter documentation & traceability

Compliance with medical device regulations

Enhanced risk management

Who Needs It: Manufacturers & suppliers of medical equipment

3. IATF 16949 (Automotive QMS)

Key Differences from ISO 9001:

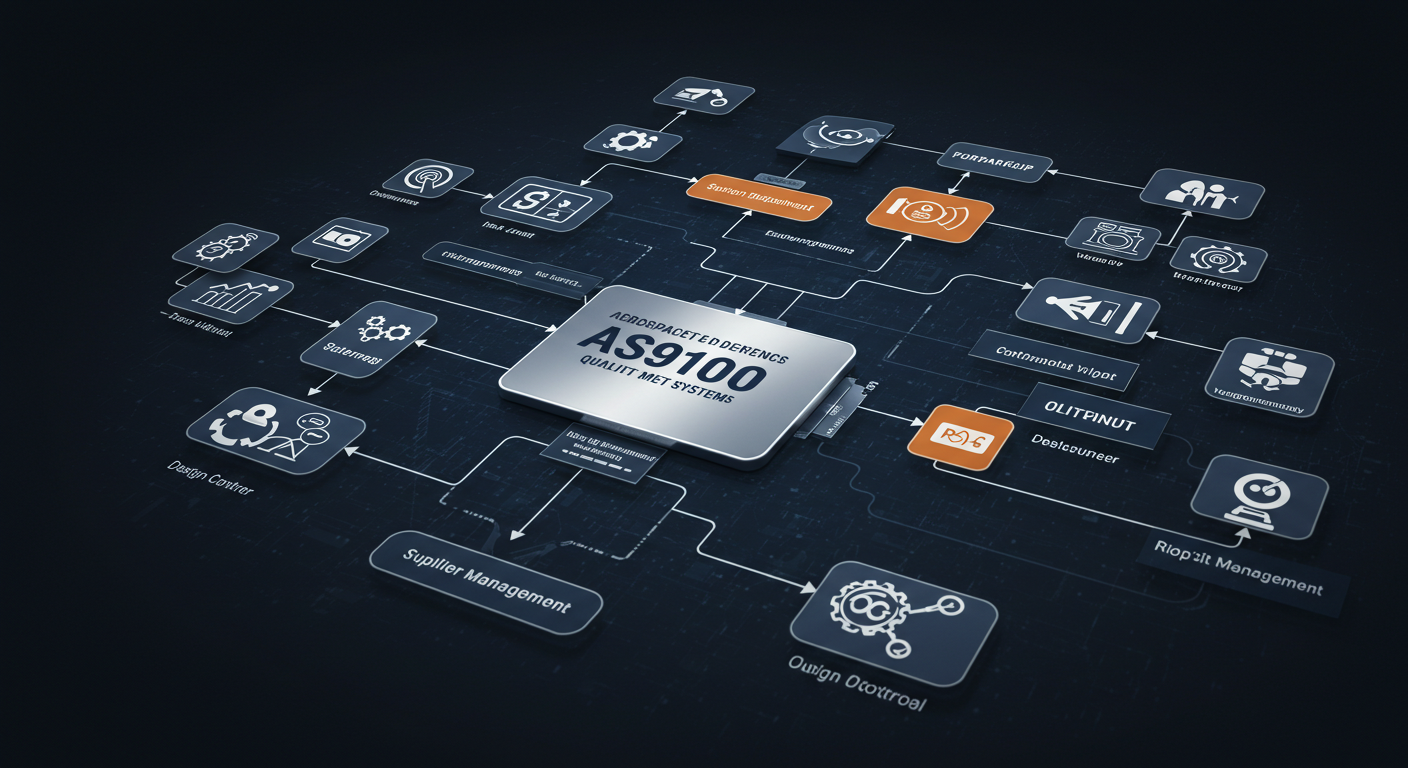

4. AS9100 (Aerospace & Defense QMS)

Unique Requirements:

First Article Inspection (FAI)

Prevention of counterfeit parts

Certification Process:

Must register in OASIS database

More frequent audits

End-to-End Quality Control: From Source to Delivery

Product Design and Quality Assurance Planning

From concept to SOP, we align design intent with rigorous QA—clear specifications, process controls, and verification steps (inspection, testing, validation) to deliver consistent, compliant performance.

Supplier Management & Raw Material Verification

Approved-vendor programs, dual-sourcing, and contractual quality clauses—backed by MTR validation, PMI/chem checks, and lot-level records—secure supply and compliance.

Design & Engineering Quality Planning

From CAD to production, our approach combines precision modeling, simulation, and prototyping with documented QA checkpoints, securing predictable performance.

End-of-Line Inspection & Functional Testing

Functional testing simulates real-world loads, pressures, and thermal conditions, validating performance against customer specifications before shipment.

Secure Packaging & Reliable Logistics

Our logistics team coordinates multimodal transport—sea, air, and rail—supported by trusted carriers and end-to-end tracking, guaranteeing on-time, damage-free delivery worldwide.

Prime's quality advantage: Reasons to choose us

Around the world, customers in precision parts manufacturing choose Prime for our unmatched quality standards and dedicated service.

1.Over Three Decades Ex

At the past three decades, we’ve developed a strong command of material behavior, advanced manufacturing techniques, and stringent quality standards. This experience enables us to achieve precise results at every stage—from tackling highly complex designs to executing efficient

2.Skilled Quality Professionals

Our team is made up of senior engineers and quality specialists well-versed in ISO 9001 and related standards. They are capable of resolving complex production quality issues and undergo continuous training to remain at the forefront of technology.

3.Modern Testing Instruments

Using CMMs, spectrum analyzers, hardness testers, metallographic microscopes, and mechanical testers—alongside SPC, FMEA, and MSA—we provide accurate, full-scale quality testing.

4.Custom Quality Management Plan

Our approach to quality control is fully tailored—integrating product applications, performance demands, and global standards. This ensures that whether for early prototypes or mass production, every solution precisely matches customer needs.

5.Quality Evolution and Customer

Guided by the philosophy of continuous improvement, we integrate data-driven analysis, systematic internal audits, and customer feedback to streamline our processes, resulting in both high-quality outputs and enhanced partnership efficiency.

6.Instant After-Service

Zero-Wait After-Service: Because your peace of mind can't wait. Our dedicated team is always on standby to provide instant help and care.Connecting you to expert help in real-time. From online troubleshooting and remote assistance to rapid parts dispatch,

Curious? So Were We.

Your project’s success depends on precision. Explore our detailed Quality Control guidelines to understand how Prime Fabworks guarantees it. Have a specific concern? Our engineering team is ready to provide clarity.

1.Which international quality standards is Prime Fabworks certified to comply with?

Your assurance of quality is our ISO 9001:2015 certification. This international standard guides our entire process, guaranteeing that every component we deliver is built to the highest specifications and reliability standards.

2.By what specific methods does Prime Fabworks maintain product uniformity?

Consistency isn't an outcome we hope for; it's a result we engineer. Our certified quality system is built on proactive controls—like SPC and IPQC—and validated by rigorous inspections (FAI and final audit). Crucially, we ensure the integrity of our data through ongoing MSA, creating a closed-loop system dedicated to delivering unwavering product uniformity.

3.What is Prime Fabworks' protocol for addressing non-conforming products?

Your satisfaction is paramount. If an issue ever occurs, our team immediately employs our structured 8D process. We will keep you informed, swiftly resolve the problem, and take definitive steps to prevent it from happening again. We see every issue as a chance to strengthen our partnership and improve our processes for you.

4.Does Prime Fabworks provide client-specific quality management solutions?

Definitely. We believe quality is a collaborative process. Our engineers will partner with you to understand your vision, application challenges, and key performance metrics. Together, we'll define and implement the most effective quality processes and inspection standards to ensure success.

5.Which aspects of Prime Fabworks' quality testing capabilities are considered most robust?

While we invest in the finest tools—like precision CMMs and material analyzers—our real strength is our people. Our experienced quality engineers leverage this technology to perform meticulous validation, giving you complete confidence in your product's dimensional accuracy, material makeup, and overall integrity.

Receive a competitive quote within 24 hours

We guarantee a competitive quote within 24 hours. By combining efficient workflows with deep industry expertise, our team ensures you receive accurate pricing, reliable lead times, and clear technical support — all designed to help you make faster and smarter purchasing decisions.

Simply Customize Metals

Finding top-quality custom metal parts doesn’t have to be complicated. At Prime, we guide you through it in three easy steps:

Three Decades of Trusted Production Experience, Delivered from Our Own Facilities

Custom-Designed Components Engineered for Your Specific Applications

Worldwide Delivery Network with End-to-End Logistics Services

Fast and Transparent Quotes with No Hidden Conditions

Your Designs and Information Stay Fully Confidential — Guaranteed

After you confirm the design and pricing, we’ll start production and manage the shipping—making sure everything arrives on time.

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.