How Do You Choose the Right Screw Head for Your Application?

Are you specifying screws for a new product, only to face stripped heads, assembly line issues, or field failures? Choosing the wrong screw head is a seemingly small detail that can cause massive production delays and costly warranty claims.

The right screw head is chosen based on a combination of required torque, tool access, final appearance, and security needs. Common drives like Phillips are for general use, while high-torque systems like Torx and Hex are essential for industrial and automated manufacturing.

From my years as a buyer in the US to now running our factory, Prime Metals, since 1993, I've seen millions of dollars wasted on poor fastener choices. A screw isn't just a piece of metal; it's a critical component that determines the strength, serviceability, and even the perceived quality of your entire product. Let's walk through how to make the right choice from both an engineering and a manufacturing perspective.

What are the most common everyday drive types?

You see these drives everywhere, from electronics to furniture. While they may seem basic, understanding their specific design intent is key to avoiding the most common fastener failure: the stripped head.

Why is the Phillips head still an industry standard?

The Phillips drive was designed to "cam-out" – meaning the driver will slip out of the head when a certain torque is reached. This was a feature, not a bug, designed to prevent over-tightening with the basic tools of its time. It's cheap to produce and universally available, making it a default for general-purpose applications where precise torque is not critical. It's a reliable choice for less demanding assemblies, but when performance is key, you must consider other options.

When is a simple slotted (flat-head) screw the best choice?

The slotted head is the oldest design. Its primary modern advantage is simplicity and aesthetics, especially in woodworking or restoration projects where a classic look is desired. However, it offers very poor torque transmission and the driver can easily slip and damage the workpiece. I only recommend it for low-stress, decorative applications. For any structural application, you'll want to specify a more robust drive type to ensure both assembly efficiency and long-term product integrity.

What is the critical difference between Phillips and Pozidriv?

This is a mistake I see all the time. A Pozidriv looks like a Phillips but has four additional small ribs. As detailed by sources like Wikipedia's fastener drive list, these ribs provide much better engagement and significantly reduce the risk of cam-out. Using a Phillips driver on a Pozidriv screw will damage the head and the tool, preventing proper tightening. If you need more torque than a Phillips can provide but don't want to switch to a hex or Torx system, Pozidriv is the superior choice.

Which drives are best for high-torque industrial uses?

When you move into machinery, automotive, and high-performance products, you need a drive system that can handle high torque without slipping or failing. This is where hex and Torx drives dominate.

Why are hex socket (Allen) screws a favorite for machinery?

The internal hex socket's key advantage is its ability to be used "blind" – you can insert the tool by feel when you can't see the head. The driver engages deeply, allowing for high torque application. The heads can be compact, fitting into tight counterbored holes. This makes them the standard for machine assembly, set screws, and anywhere a protected, high-strength fastener is needed. Their widespread availability and simple tool requirements make them a reliable workhorse for countless industrial applications.

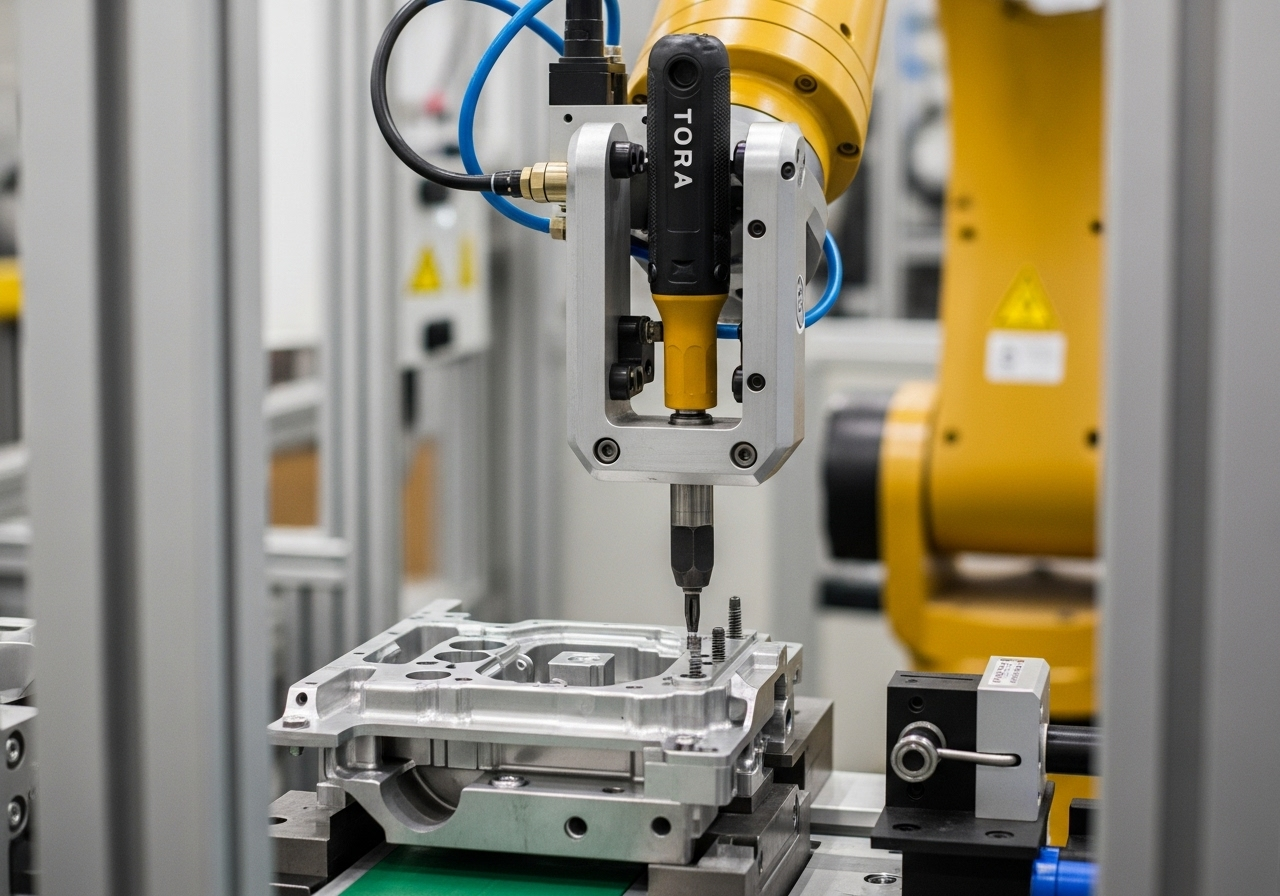

How did Torx (star) become the superior choice for manufacturing?

The Torx drive, standardized under codes like ISO 10664, was engineered to eliminate cam-out completely. Its six-point star design with vertical walls allows for a near-perfect transfer of rotational force. This means you can apply higher torque, dramatically increase the life of both the driver bit and the screw, and it's ideal for automated assembly lines where consistency is everything. When a client's product requires absolute reliability and high clamping force, we almost always recommend a Torx drive.

Hex vs. Torx: Which is better for your application?

While both are excellent for high-torque situations, the choice often comes down to the details. I always advise clients to consider the entire product lifecycle.

| Feature | Hex Socket (Allen) | Torx (Star Drive) |

|---|---|---|

| Torque Transfer | Good, but stress is concentrated on 6 corners | Excellent, force is distributed over a larger surface area |

| Cam-Out Risk | Low | Virtually zero |

| Tool Wear | Can round off over time with heavy use | Significantly longer tool life |

| Best For | Machine assembly, set screws, DIY kits | Automated manufacturing, high-torque, serviceability |

| My Factory View | A reliable, cost-effective workhorse. | The premium choice for high-performance applications. |

How do security screws protect your products?

When a product is installed in a public space or contains sensitive components, you need to prevent unauthorized access. Tamper-resistant screws are the first line of defense.

How do tamper-resistant screws work?

Security screws feature an unconventional drive that cannot be turned with a standard Phillips or flat-head screwdriver. The goal is to require a specific, less common tool for removal. This simple barrier is often enough to deter casual vandalism, theft, or tampering with settings on public equipment like ticket machines or park benches. It's a low-cost insurance policy against unauthorized access, protecting both the product and the public from potential harm or misuse.

What are the common types of security drives?

There are many designs, but some of the most common are the custom screws we can produce for specific client needs, including:

- Pin-in-Torx / Pin-in-Hex: A standard Torx or hex drive with a small metal pin in the center, requiring a hollow-tipped driver. This is one of the most common and effective security systems.

- Spanner (Snake Eye): A head with two small holes, requiring a two-pronged driver. We often see this used in architectural or aesthetic applications where appearance is also a factor.

- One-Way Screws: These can be installed with a standard flat-head driver but have sloped ramps in the drive that prevent removal. They are ideal for permanent installations.

When should you specify a security head?

Use a security fastener when the cost of unauthorized access is higher than the small premium for the screw. This includes public fixtures, electronic enclosures, safety guards on machinery, and any product where internal user service is discouraged. I've seen clients use them to protect valuable electronics, prevent liability from user tampering, and maintain the integrity of calibrated equipment. It's a small investment in liability protection and product integrity.

How does the head shape affect function?

The drive type is what the tool engages, but the overall shape of the head is what holds your assembly together. Choosing the wrong shape can lead to weak joints or an unprofessional finish.

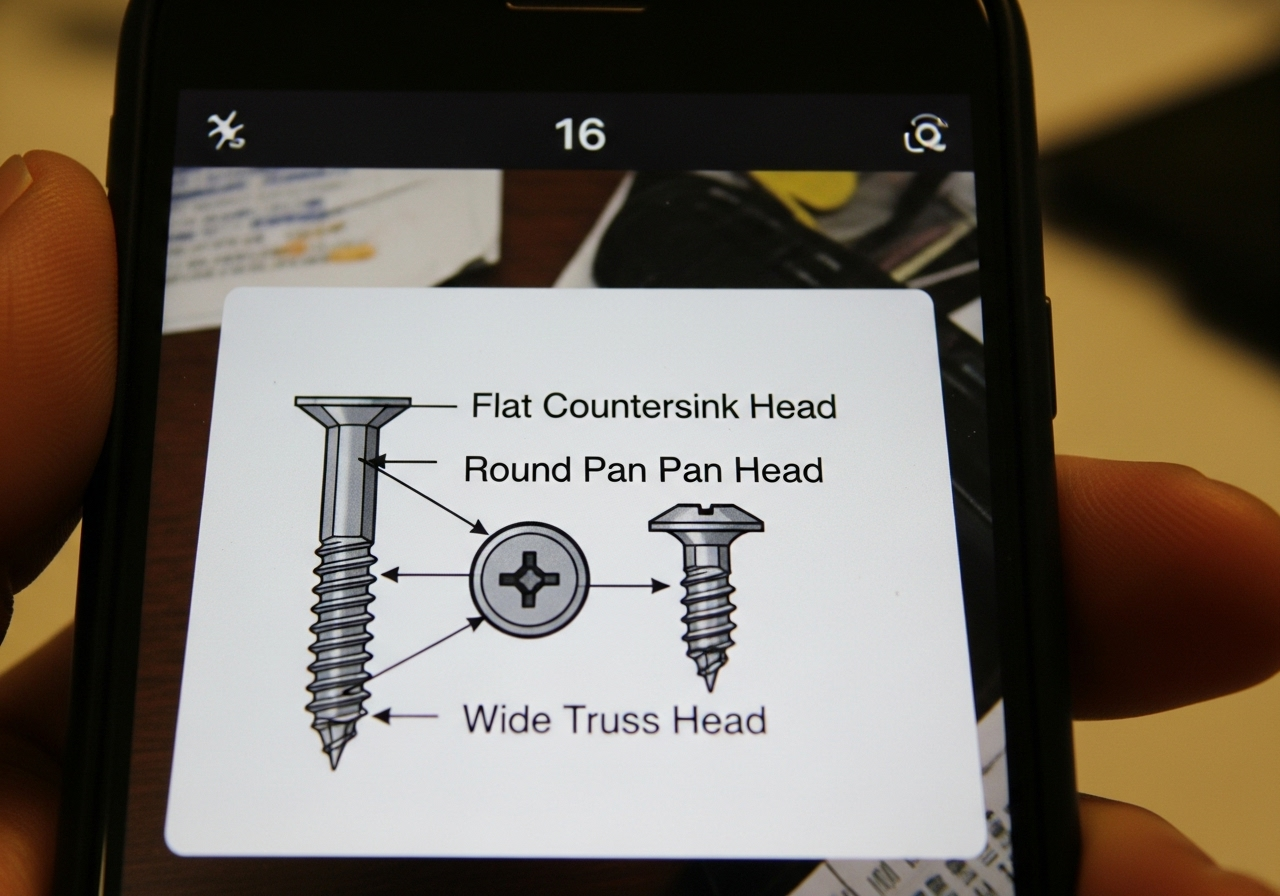

Pan vs. Flat (Countersunk) Heads: Which Sits Where?

This is the most fundamental choice in head shape. A Flat or Countersunk head has a conical shape on its underside, designed to sit flush with or below the surface of the material in a pre-drilled countersunk hole. You choose this head when a smooth, snag-free surface is a requirement for either function or aesthetics. A Pan head has a flat bottom and a slightly domed top, so it sits proudly on the surface of the material. It provides good clamping force without needing a special hole drilled, making it simpler and faster for many assemblies.

Why use button or dome heads?

Button heads and dome heads have a lower, wider profile than pan heads and are often used for their aesthetic appeal and snag-resistant design. The smooth, rounded shape is also a safety feature, making them ideal for products that people will handle, like playground equipment, furniture, or consumer electronics. The absence of sharp edges reduces the risk of cuts or clothing snags. We often recommend them for products where the final look and feel are a key part of the brand's quality perception.

When are truss or wafer heads necessary?

A Truss head (also known as a Wafer head) is very wide and has a very low profile. Its key feature is a large bearing surface under the head. This spreads the clamping force over a much wider area, which is perfect for securing thin materials like sheet metal, soft plastics, or fragile composites. This prevents the head from pulling through the material under load, which is a common failure point when using a standard pan head in these applications.

How do material and finish affect performance?

The base material and any applied coating determine a screw's strength, corrosion resistance, and cost. This choice is entirely dependent on the environment your product will live in.

Why is stainless steel the standard for corrosion resistance?

For any application exposed to moisture, chemicals, or outdoor conditions, stainless steel is the go-to material. We primarily work with two grades:

- Grade 304 Stainless Steel: This is the most common and cost-effective grade for general corrosion resistance. It's perfect for kitchen appliances, indoor hardware, and general outdoor use.

- Grade 316 Stainless Steel: This grade contains molybdenum, giving it superior resistance to chlorides (like salt water or de-icing salts). It is absolutely essential for marine hardware, medical devices, and equipment used in food processing plants.

What are common coatings and why use them?

For dry, indoor applications, a coated carbon steel screw is a more economical choice. The coatings provide a necessary layer of protection.

- Zinc Plating: This is the most common finish for commercial hardware. A thin layer of zinc is applied electrolytically to provide a basic level of rust protection and a clean, bright finish.

- Black Oxide: This is a conversion coating that turns the surface of the steel black. It provides mild corrosion resistance and a desirable aesthetic, but it must be kept lightly oiled to prevent rust in the long term.

Can you get screws in specialty materials?

Yes. For extreme applications, standard materials won't work. We can machine fasteners from a range of specialty metals to meet unique performance demands. Brass is often used for its decorative appeal and inherent corrosion resistance in plumbing fixtures. Titanium is specified in aerospace and medical applications for its incredible strength-to-weight ratio and biocompatibility. When standard fasteners won't do, our team can work with your engineers on custom solutions.

About the Author

My name is Kevin. I started my career in the US, sourcing industrial components. I learned every hard lesson there is about fasteners—from the frustration of stripped heads on an assembly line to the liability of a corrosion failure in the field. Since 1993, I've put that experience to work here at Prime Metals, building a factory that understands the quality and communication standards Western buyers expect. We don't just sell screws; we provide engineered solutions.

Frequently Asked Questions (FAQs)

What is the difference between a screw and a bolt?

Generally, a screw is designed to thread into a pre-tapped hole in a material, while a bolt is designed to pass through unthreaded holes and be secured with a nut. The Industrial Fasteners Institute (IFI) provides precise technical definitions, but this is the common practical distinction for most engineers and buyers.

What is "cam-out" and why does it matter?

Cam-out is the process where a driver bit, under torque, is forced up and out of the screw's drive recess. It's very common with Phillips heads and leads to stripped screws and damaged driver bits. In a manufacturing setting, this slows down assembly, causes quality control failures, and increases costs due to rework and fastener replacement.

How do you measure a screw's length correctly?

This depends on the head type. For screws that sit on top of the surface (like Pan, Truss, or Hex heads), length is measured from the flat underside of the head to the tip of the screw. For Flat (Countersunk) screws that sit flush, the length is measured from the flat top of the head to the tip, including the head in the total length.

Do I need a different screw for metal versus wood?

Absolutely. Screws for metal typically have fine, consistent machine threads designed to engage with a pre-tapped hole or a nut. Wood screws have coarser, sharper threads designed to cut their own path into wood fibers and provide strong holding power. Using the wrong type will result in a weak or failed joint.

Your Next Step

Choosing the right fastener is a critical engineering decision that impacts your product's performance, durability, and cost. By understanding the function behind each head and drive type, you can make an informed choice that will save you time and money.

Ready to source the right fastener with confidence? Our team can help.