Reliable Supplier Precision CNC Parts

Frequently Used Custom CNC Parts Styles

PRIME builds precision CNC Parts to the highest standards of strength, reliability, and customization

Precision Customsized Fasteners

Wind Turbine Gearbox Housing

Applications: Offshore Wind Turbines, Floating Platforms, Coastal Wind Installations

Industry intro: Wind turbine gearbox housings must withstand salt spray, humidity

Engine Cylinder Head Cover

Applications: Automotive ICE/Hybrid Platforms, Light Commercial Vehicles, Buses

Industry intro: Engine cylinder head covers must maintain gasket compression, manage blow-by

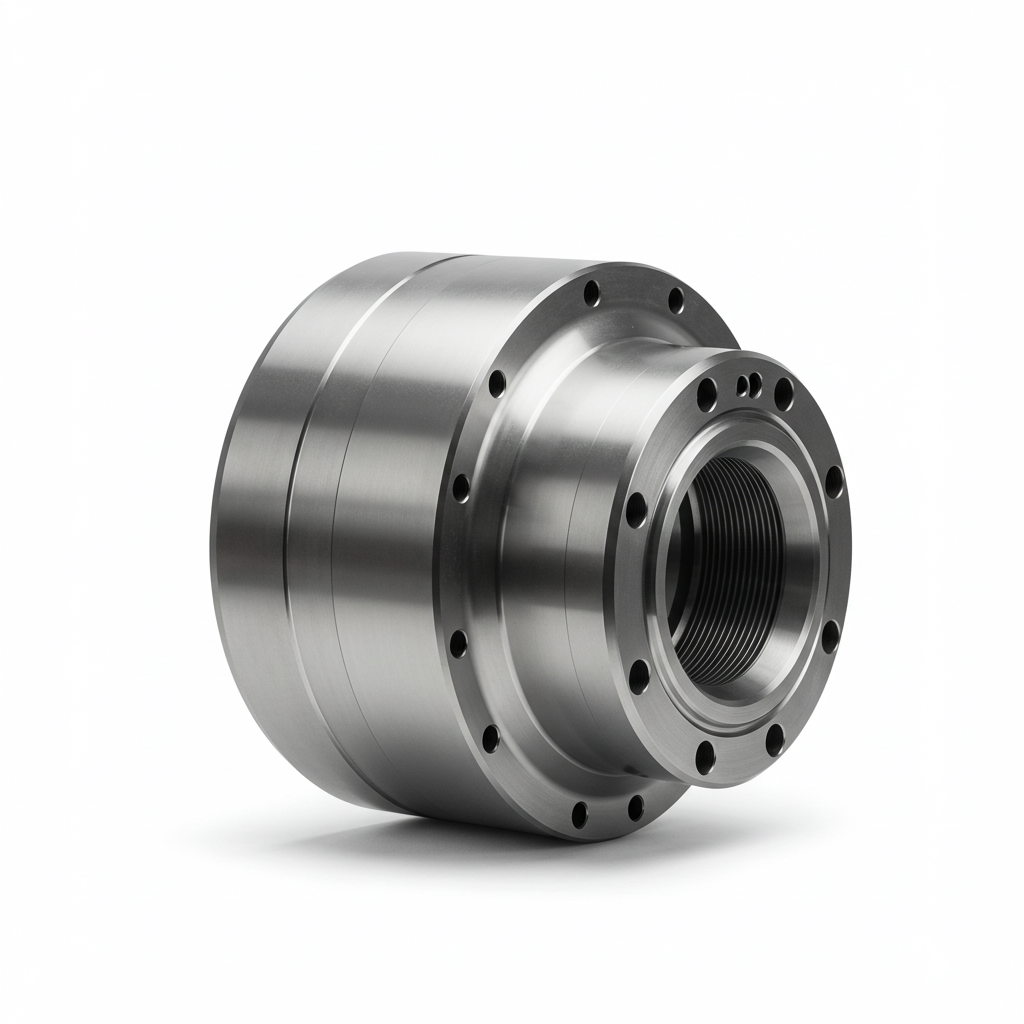

Brake Disc Hub

Applications: Heavy-Duty Trucks, Urban Buses, Long-Haul Coaches

Industry intro: Under high loads and frequent stop–start duty, brake disc hubs must resist distortion, fretting, and thermal cycling.

Landing Gear Component

Applications: Helicopters, Military Transports, Special-Mission Aircraft

Industry intro: Mission-critical landing gear components face variable impact energies, vibration, and off-nominal landings

Surgical Instrument Handle

Applications: Minimally Invasive Surgery, General Surgery, Orthopedics

Industry intro: The medical device sector demands surgical instrument handles with precise ergonomics, sterilization resilience

MRI Scanner Component

Applications: Medical Imaging, MRI Systems, Radiology Equipment

Industry intro: The medical imaging sector demands MRI scanner component housings that are non-ferromagnetic, structurally rigid

Why Choose Prime: Unlocking the Advantage in CNC Parts Supply

Choosing a reliable CNC machining supplier is more than a purchase—it is a strategic move that determines product accuracy, project efficiency, and supply chain resilience. Prime brings decades of manufacturing experience, cutting-edge CNC equipment, strict inspection standards, and a service culture built around our customers. With scalable capacity, precision technology, and global logistics coverage, Prime is your dependable partner for CNC parts of every specification.

- 30+ Years of Proven Expertise: Established in 1993, our deep industry knowledge empowers us to tackle complex challenges and deliver consistent excellence.

- ISO 9001:2015 Certified Quality: Our entire process—from material sourcing to final inspection—follows rigorous international standards to ensure reliable output.

- 15 Advanced Production Lines: Our high-speed infrastructure handles large orders with agility and scale, keeping your production timeline intact.

"Need a CNC Parts That Actually Meets Your Specs?"

Upload your design drawings and part specifications using our safe online portal. Within 24 hours, our expert engineering team will review feasibility and provide a cost-effective quotation.

Let’s transform your vision into world-class components.

In modern industry, customized metal fasteners are indispensable, ensuring reliability in demanding fields such as construction, automotive, energy, and machinery manufacturing. Prime specializes in producing tailored fastening solutions, combining precision metalworking with strict quality standards.

Custom-Engineered CNC Parts for High-Stakes Applications

Across industries such as construction machinery, automation systems, rail transit, petrochemical plants, and marine engineering, custom CNC parts are the foundation of efficient and reliable operations. Engineered with outstanding precision, load-bearing capacity, and resistance to fatigue, they ensure stable performance even under extreme conditions.

At Prime, we offer end-to-end CNC services—from technical drawings to full-scale production and worldwide distribution. Our advanced machining capabilities and strict quality control guarantee CNC parts that meet the toughest industrial demands and international specifications.

Frequently Asked Questions on CNC Machined Parts

As part of our commitment to customer support, we’ve compiled an FAQ guide that highlights key information about CNC parts and Prime’s services. Each question is answered with precision and clarity, ensuring you can make informed choices while avoiding the frustrations of miscommunication.

With machining precision up to ±0.005 mm, Prime ensures components meet the most demanding requirements for fit and function. Supported by advanced inspection equipment—such as coordinate measuring machines, altimeters, and surface roughness testers—we conduct rigorous quality checks on every batch. Detailed size reports and test records are delivered to guarantee error-free assembly and reliable operation.

Of course. Whether your design requires thin-walled structures, non-standard cavities, or precision curved surfaces, Prime can manufacture CNC parts to match your specifications. Our 5-axis machining centers and experienced engineers ensure efficient production from concept to finished part. We also provide design-for-manufacturing guidance to help you achieve a balance between functional design and practical production.

Our CNC machining capabilities cover a broad selection of materials, from aluminum alloys and stainless steels to carbon steel, copper, brass, and engineering plastics like POM and PTFE. To ensure supply chain integrity, all materials are traceable and can be certified with EN10204 3.1 reports, RoHS, REACH, or other compliance documents as required—supporting both quality assurance and regulatory compliance.

Of course. Prime’s engineering team collaborates with customers to evaluate designs and propose manufacturing-friendly improvements. By optimizing elements such as material choice, thickness, chamfer design, and tool paths, we help balance function with efficiency—delivering parts that are cost-effective, easy to machine, and reliable in use.

To ensure safe transit and compliance, all products receive anti-rust treatment, are individually packed in polybags or boxes, then secured in export-ready cartons on fumigation-free pallets. We provide flexible trade terms (CIF, FOB, DDP) and complete documentation, including Certificate of Origin, Form A/E, and HS codes.

Absolutely. With two decades of global export experience, PRIME supplies clients throughout Europe, the U.S., the Middle East, and Australia. Every shipment is secured with layered protective packaging, including rust-preventive coatings, bubble film, moisture barriers, cushioning foam, cartons, and export-ready wooden cases. We accommodate FOB, CIF, DDP, and other trade terms, while also preparing customs clearance paperwork—so your order arrives safely and hassle-free.

First:What exactly is a CNC machined product?

A CNC machined part is produced when a computer-controlled machine removes material from a solid block, forming precise shapes according to digital instructions. With automated milling, drilling, and turning, CNC machining ensures tight tolerances and consistent quality, even in complex geometries.

From simple geometries to complex, high-precision designs, CNC machining delivers parts with exceptional tolerance control. Compatible with a wide variety of metals and plastics, it is well-suited for prototyping, flexible production volumes, and final-use parts in industries where quality and consistency are critical.

Essential Qualities of CNC Machined Parts

State-of-the-art CNC machines are capable of reaching tolerances as precise as ±0.002 mm (±0.00008 in.). Such accuracy is achieved through rigid machine setups, optimized tool paths, and advanced in-process measurement systems that ensure consistent precision throughout production.

With CNC machining, you can choose from metals like aluminum, stainless steel, brass, and titanium, as well as engineering plastics such as POM and PEEK, plus advanced alloys. The right material is chosen according to strength, heat resistance, and appearance needs.

Non-Standard Structures

Whether producing low volumes or scaling to full production, CNC machining ensures accuracy and repeatability. By eliminating the need for dedicated molds, it reduces costs, shortens delivery times, and supports agile manufacturing.

Common CNC Machining Processes

- Milling: Material is removed using multi-axis rotating cutters, enabling precision machining of both planar and contoured surfaces.

- Turning: The workpiece is rotated while a fixed cutting tool machines it into cylindrical or conical shapes—commonly applied in producing shafts, bushings, and other round components.

- Drilling: Precisely creates holes and internal threads of varying depths and diameters.

- Heat Treatment: Enhances strength, hardness, and performance through controlled tempering and quenching processes.

- Tapping: Comprehensive dimensional and visual inspections are performed with optical sorting systems, thread gauges, and hardness testers to ensure full compliance.

- Boring: Refines and enlarges existing holes to meet precise dimensional tolerances.

Essential structural parts, engine brackets, housings, and precision fittings designed for lightweight performance and dependable reliability.

Precision fasteners used in airframes, turbines, and cockpit assemblies with exacting strength-to-weight standards.

Miniature fasteners for circuit boards, enclosures, and heat sinks — tailored for conductivity and compact form factors.

High-load bolts, nuts, and washers for machines, conveyors, and power systems where reliability is critical.

Corrosion-resistant fasteners for offshore platforms, bridges, ships, and infrastructure exposed to harsh environments.

Industries That Rely on Custom Fasteners

Second:Discover CNC Components and How They’re Made

Comprehensive for Guidance

If you’re sourcing CNC parts for the first time or aiming to optimize your existing supply chain, this section gives you a clear understanding of CNC machining and how PRIME ensures world-class accuracy. We outline the fundamentals, demonstrate our expertise, and share how our tailored services help overcome typical industry challenges—so you can make informed decisions with confidence.

The Basics of CNC Machining: What You Need to Know

CNC machining is a modern manufacturing process where computer-controlled machines carve material away from a solid block to make accurate parts. Through programmed tool paths, these machines can perform milling, turning, drilling, and shaping on both metals and plastics. It’s perfect for creating complex parts in smaller production runs with high precision and repeatability, widely used in sectors like aerospace, cars, and medical technology.material, guaranteeing a perfect connection.

Selecting the Optimal Machining Process: Precision Matched to Your Needs

Selecting the right CNC method helps achieve the best mix of accuracy, speed, and budget. At PRIME, we adapt our machining approach to your chosen material, required tolerances, and unique design needs. Our engineers carefully assess your drawings and suggest the best solution for reliable function and cost efficiency. Here are the main CNC processes we provide:

1. CNC Milling: Accurate Machining for Multi-Axis Geometries

From flat surfaces and slots to deep pockets and intricate 3D contours, CNC milling offers unmatched versatility for components such as housings, frames, and mold bases. PRIME’s high-performance 3-, 4-, and 5-axis mills meet demanding tolerance requirements with fewer setups. Equipped with automated clamping and continuous measurement systems, we ensure exceptional precision with fast turnaround.

2. CNC Turning: Ideal for Shafts, Bushings, and Round Parts

Unlike cutting, which weakens the metal, our thread rolling process actually strengthens it. This is why leading industries rely on rolled threads for essential fasteners like screws and bolts. PRIME leverages state-of-the-art flat and planetary die systems to guarantee that every thread delivers optimal load distribution and strict adherence to ISO, UNC, and DIN specifications.

CNC Machined Parts: A Practical 2025 Guide for OEM Buyers

CNC Machining Services in China for Small Batches (5–200 pcs): Price & Lead Time Guide

CNC Machining Services in China for Small Batches (5–200 pcs): A Price & Lead Time Guide? leading paragraph: Are you being ignored by large factories

Chamfer 101: A Complete Guide for Engineers and Manufacturers?

Chamfer 101: A Complete Guide for Engineers and Manufacturers? Are your parts arriving with dangerously sharp edges that can injure technicians? Or are you struggling

How does Prime ensure dimensional accuracy and surface finish quality in CNC machining?

How does Prime ensure dimensional accuracy and surface finish quality in CNC machining? Have you ever received a batch of CNC parts where the first

3. Design Without Boundaries: 5-Axis CNC Machining

By moving along five axes simultaneously, 5-axis machining makes it possible to manufacture intricate designs and multi-surface parts in just one operation. It’s widely used in critical sectors such as aerospace, medical devices, and defense, where tight tolerances and reliability are essential. PRIME leverages 5-axis technology to minimize setups, cut lead times, and achieve exceptional consistency.

4. Precision Drilling and Tapping for Dimensional Accuracy

Critical to many assemblies, drilling and tapping provide exact holes and internal threads for parts in the electronics, automotive, and equipment sectors. PRIME’s CNC machining centers employ rigid tapping and peck drilling methods, supported by real-time feedback systems, to deliver superior thread integrity and precision. Our capabilities include metric, imperial, and custom profiles with dependable consistency.

Guidance from CNC Experts for Smarter Purchasing

Providing target quantities, chosen materials, and tolerance requirements early in the quoting process helps us identify the most suitable machining method. This allows PRIME to streamline setup, reduce costs, and ensure the finished product fully meets your application demands.

Third: The Role of Material Choice in CNC Machining Success

The performance of custom fasteners depends greatly on material choice, which influences durability, corrosion resistance, and functional safety. PRIME offers a deep understanding of material properties and assists clients in selecting the most suitable grade for their specific application. From tensile bolts to weatherproof screws, we ensure quality and reliability.

PRIME Expertise in Fastener Material Evaluation and Selection

We do more than manufacture parts—we help you pick the right material for your application. PRIME provides expert advice and documented traceability so your components meet strength, safety, and appearance requirements with confidence.

Raw Material Certification and Testing

PRIME ensures complete traceability: each material batch includes chemical and mechanical certifications confirming alloy composition, hardness, and tensile performance—delivering guaranteed compliance with worldwide standards

CNC-Focused Design for Manufacturing

We guide clients in selecting suitable materials for thread rolling, head forming, and plating compatibility. Our DFM support ensures your fasteners are both cost-effective and high-performing in end-use conditions.

Comprehensive Lifecycle Cost Analysis

Our analysis goes beyond material pricing, taking into account cutting speed, tool wear, finishing requirements, and downstream processing. This approach ensures smarter decisions and minimized total cost of ownership.

Common Materials and Their Characteristics

Alloy Materails

Aluminum 6061-T6 / 6082-T6 – Workhorse grade; strong, light, easy to machine; great for anodizing, fixtures, housings.

Stainless steel 303 – Best machinability among stainless; shafts, fittings; lower corrosion resistance.

Carbon & alloy steels 1018/1020 – Low-carbon, economical; spacers, brackets; case-harden or plate for wear/corrosion.

Titanium Grade 2 – Corrosion-resistant, formable; medical/chemical hardware.

Fourth: Optimized Surface Finishes for CNC Machined Parts

Finishing treatments not only improve the look of CNC parts but also add protection and dimensional stability. At PRIME, we deliver tailored surface finishes that meet demanding performance criteria, cosmetic standards, and regulatory requirements.

- Anodizing (for Aluminum): Makes parts stronger against wear and rust, with clear or colored finishes that look great and protect at the same time.

- Electroplating: Electroplated coatings such as zinc, nickel, or chrome are applied to increase wear resistance and corrosion protection in line with ASTM B633 standards.

- Powder Coating: Provides a hard-wearing, UV-resistant surface finish, customizable in RAL/PANTONE color options to meet specific requirements.

- Blasting: Achieves uniform matte textures that reduce glare and improve adhesion in later processes.

- Passivation: Ensures a uniform matte finish, reducing surface shine while promoting better adhesion for secondary operations.

- Polishing and Deburring:Both automated and skilled manual processes are applied to remove burrs and sharp edges, supporting precision fit and assembly safety.

Fifth: CNC Accuracy is Driven by Advanced Toolpath Strategies and Rigid Fixtures

High-quality fasteners begin with high-precision tooling. PRIME designs and manufactures threading dies, cold heading molds, and trimming tools in-house to achieve dimensional accuracy

1.Thread Rolling Dies: Precision-ground HSS or carbide dies ensure consistent threads for each production run.

2.Heading & Trimming Dies: High-strength steel tooling supports complex head forms and special features.

3.CNC Machined Tooling: ±0.01 mm tolerance for dies used in high-speed multi-stage machines.

4.Die Coatings: PVD, TiCN, and nitriding treatments extend tooling life and reduce galling.

5.Trial Runs & Validation: All tools are tested in actual production speed to validate repeatability and lifespan.

Sixth: Consistent Quality Management Across CNC Processes

Keep your parts protected. The right surface finish makes fasteners stronger, longer-lasting, and resistant to rust. PRIME selects the best finishing process based on your application and environment to guarantee reliable performance.

1.Material Traceability: Full documentation with MTCs (Material Test Certificates) including chemical and mechanical data.

2.Process Control: Torque testing, plating thickness, thread profile inspection performed in-line.

Dimensional Inspection: 100% sampling with GO/NO-GO gauges and precision measurement tools.

3.Mechanical Testing: Tensile, hardness, shear, and fatigue tests per ASTM, ISO, or DIN standards.

4.Packaging & Compliance: Labeled, barcode-tracked packaging with RoHS/REACH/COC documents included.

CNC Parts Quality Inspection Process

1.Raw Material Verification

Before machining begins, all raw materials such as steel, aluminum, brass, titanium, or plastics are checked for compliance with specifications. This includes verifying supplier certificates, inspecting dimensions, and confirming chemical and mechanical properties. Ensuring material accuracy from the start prevents defects and guarantees consistent part performance.

2. CNC Program and Setup Validation

Before production, CNC programs and machine setups are validated. Trial runs or simulation checks are conducted to confirm tool paths, cutting parameters, and fixture stability. This step ensures machining accuracy and minimizes errors during mass production.

3. First Article Inspection (FAI)

A first-off part is produced and thoroughly inspected against drawings and 3D models. Dimensional tolerances, hole positions, surface finish, and thread quality are checked using calibrated instruments. This validation step confirms that the CNC process is capable of delivering required specifications.

4. In-Process Quality Control (IPQC)

During machining, operators and inspectors perform checks at defined intervals. Critical dimensions, tool wear, and surface quality are monitored in real time. This allows quick corrections, reduces scrap, and ensures stability across production batches.

5. Dimensional & Geometric Inspection

Surfaces are inspected for machining marks, burrs, scratches, or tool chatter. Deburring and polishing may be applied to remove sharp edges and achieve required Ra surface finish values. This ensures both functional reliability and aesthetic quality.

6. Surface Finish & Defect Inspection

Surfaces are inspected for machining marks, burrs, scratches, or tool chatter. Deburring and polishing may be applied to remove sharp edges and achieve required Ra surface finish values. This ensures both functional reliability and aesthetic quality.

7. Functional and Assembly Testing

For parts that interact with other components, functional testing is carried out. This may include thread gauge testing, tolerance stack-up verification, or trial assembly. The goal is to confirm that CNC parts integrate seamlessly into the final application.

8. Final Quality Assurance (QA) Check

Each batch undergoes a comprehensive final inspection before shipment. Reports including Certificates of Conformance (COC), material certificates, and inspection data are prepared for full traceability. This step certifies that only conforming parts are released to customers.

Seventh:Defects in CNC Machining and How PRIME Prevents Them

Because CNC machining demands accuracy at every step, even slight imperfections can compromise assembly. At PRIME, we rely on advanced software, systematic checks, and strict process control to maintain quality and reliability.

1. Residual Tooling Impressions and Surface Deviations

Description: Irregular lines or rough patches that occur due to tool wear, improper feed settings, or overlapping toolpaths.

PRIME Solution:Real-time monitoring, parameter optimization, and finishing treatments for consistent part aesthetics and performance.

2. Exceeding Dimensional Limits

Description: Dimensional errors can arise from thermal effects, machine limitations, or distortion during workholding.

PRIME Solution: Precision 5-axis equipment, calibrated touch probes, and coordinate measuring validation safeguard tolerances down to ±0.005 mm.

3. Machining-Induced Sharp Edges

Description: Irregular metal projections generated during cutting or machining operations.

PRIME Solution: Edge refinement using brush, ultrasonic, or laser methods secures safe handling and accurate assembly tolerances.

4. Chatter-Induced Surface Defects

Description: Irregular machining lines created by unstable cutters, machine vibration, or improper workholding.

PRIME Solution: Robust fixtures, damped cutting tools, and variable spindle speed settings ensure smooth, vibration-free surfaces.

5. Alignment Issues in Multi-Face Machining

Description: Positional deviations between faces resulting from datum shifts during part repositioning or inter-machine transfer.

PRIME Solution: Specialized fixtures, rotary indexing tables, and probing systems maintain accurate datum alignment on every face.

Eighth:Choosing the Best CNC Parts Manufacturer for Your Needs

Partnering with the right CNC supplier isn’t only about cost. Your decision affects dimensional precision, lead times, and long-term savings. Below are six essential factors to weigh when evaluating potential CNC machining suppliers.

1.Machining Capabilities & Resources

2.Quality Systems & Accreditation

- Can they machine advanced parts using 3-axis, 4-axis, or 5-axis equipment?

- Do they maintain state-of-the-art, automated, and regularly calibrated machines?

- Are they capable of working with your chosen materials — from metals like aluminum and titanium to plastics?

- Is the supplier accredited to recognized standards like ISO 9001, IATF 16949, or AS9100 (aerospace)?

- What inspection technologies are in place — CMMs, optical scanning devices, or statistical process control (SPC) systems?

- Do they provide quality documentation such as First Article Inspection (FAI), Production Part Approval Process (PPAP), and full material/process traceability reports?

3.Proven Track Record with Intricate Parts

4.Production Capacity & Scalability

- Do they have experience producing tight-tolerance, multi-step, or assembly-ready components?

- Are they skilled in applying DFM (Design for Manufacturability) principles to CNC parts?

- Can they support both high-mix/low-volume orders and large-scale production runs?

- What is the size of their machine fleet, and how is production scheduled across shifts?

- Do they have the capacity to accelerate throughput for sudden order increases?

- On average, what is the cycle time from purchase order to shipment?

5.Clear Communication and Technical Support

6.Distribution, Packaging & Site Location

- How responsive are they to quotation requests and engineering documentation?

- Is a dedicated technical engineer or account manager assigned to your project?

- Do they offer design-for-manufacturability (DFM) reviews or engineering consultation services?

- Is protective packaging engineered to safeguard parts from abrasion, impact, or distortion in transit?

- Does the supplier manage export compliance, including documentation, HS codes, and shipment labeling?

- Are multiple logistics channels available, including expedited air freight and consolidated sea freight?

PRIME ensures compliance and performance above standard requirements. Leveraging 30+ years of machining expertise, ISO-accredited production systems, and 10 state-of-the-art CNC lines, we remain a reliable supplier for global engineering teams..

Ninth:Applying DFM to CNC Machining Processes

Improve precision, optimize cost efficiency, and speed up production with tailored DFM expertise for CNC parts.

Buyer's pain:“The part has strict dimensional tolerances and complex geometries. I’m worried this will lead to extended cycle times, wasted material, and expensive corrections. How can I make sure it’s CNC-efficient?”

“Working as part of your engineering team, PRIME provides DFM expertise to make sure CNC parts are both high-performing and optimized for accuracy, repeatability, and cost-effective manufacturing.”

1.Design Validation & Feasibility Evaluation

We review your fastener designs to confirm that key features like threads, heads, and shafts are ideal for cold heading and rolling. We also recommend simplifying shapes to extend tool life and ensure smoother production.

2.Choosing the Right Material & Managing Costs

Picking the Right Metal: We help you choose the best material—like carbon steel, stainless, brass, or titanium—based on your needs for rust resistance, strength, and cost.

Smarter Shank Sizing: We calculate the perfect starting diameter for the shank to use less material during thread rolling and minimize wasted machining.

Plan Ahead for Strength: We define the required strength level from the start to prevent heat treatment problems like cracking or brittleness later on.

3.Streamlined Geometry & Efficient Production

Checking for Rolled Threads: We verify that the thread’s specifications are designed to be made by rolling, ensuring a high-quality, strong result.

Crack-Free Forming: The geometry is designed so metal can flow smoothly into the head and shank without splitting or developing flaws.

Optimizing Head Shape: We advise on the best angles, grooves, and widths for the fastener head to extend tool life and ensure torque is applied effectively.

4. Balancing Precision with Machinability

Precision Fit: We select the exact tolerance grade for your fastener to ensure it fits your mating part perfectly, preventing damage from being forced in.

Accounting for Coating: We slightly undersize parts before coating so that after zinc, phosphate, or Dacromet is applied, they still fit perfectly and don’t get stuck.

Ensuring a Secure Connection: We analyze the fit between mating threads to make sure you can achieve the proper tightness

Tenth:Choosing Between CNC Machining and Metal Stamping for Your Parts

In metal component sourcing, the choice between stamping and CNC machining depends on factors such as part geometry, tolerance requirements, production volume, and material yield. Since PRIME operates both stamping presses and CNC machining lines, we can provide unbiased process selection to optimize performance and cost.

At PRIME, we don't believe in a one-size-fits-all solution. We custom-manufacture fasteners to your exact needs, including material, strength, thread type, and precision tolerances

Through dies and high-tonnage presses, metal stamping transforms flat metal sheets into complex parts, making it an ideal method for high-volume manufacturing.

- Scalable cost efficiency: Tooling amortization makes stamping highly cost-effective for long production runs.

- High cycle speed: Progressive dies enable parts to be produced in just seconds per stroke.

- Superior material yield: Cold forming minimizes waste relative to machining processes.

- Dimensional repeatability: Hard tooling guarantees precision and stability batch after batch.

- Optimized for sheet profiles: Ideal for components with flat geometries, piercings, and bends.

As a subtractive method, CNC machining mills, drills, and turns solid materials into final components with micron-level precision.

- Micron-level accuracy: Supports intricate 3D features and close tolerances unattainable by stamping.

- Broad material compatibility: Capable of machining hardened steels, alloys, plastics, and heavy stock.

- Prototype and low-volume friendly: Eliminates the need for costly die or tool fabrication.

- CAD/CAM-driven adaptability: Design revisions are implemented digitally without retooling.

- Superior finishing capability: Achieves refined surface quality, minimizing polishing or grinding.

At PRIME, we go beyond single-process manufacturing. With expertise in both CNC machining and precision metal stamping, we analyze your project requirements and advise the most efficient, cost-effective solution. Share your part specifications with us, and our engineers will recommend the optimal production method.

Eleventh:Worldwide Supply Chain Solutions: Consistent and Efficient Delivery

Manufacturers and distributors, reliable delivery is just as critical as precision fasteners. With 30+ years of international expertise, PRIME guarantees secure packaging, on-time fulfillment, and complete supply chain visibility – wherever your operations span

Buyer Concern“What steps can I take to guarantee on-time delivery from overseas suppliers, avoiding customs issues and hidden charges?”

“The part has strict dimensional tolerances and complex geometries. I’m worried this will lead to extended cycle times, wasted material, and expensive corrections. How can I make sure it’s CNC-efficient?”

1.Trade Compliance & Export Expertise

- Thread Rolling and Lathe Turning: Manufacture of accurate internal and external threads

- Precision Slotting & Grooving: Machining keyways, circlip grooves, and custom profiles.

- Micron-Level Tolerancing: Finishing to exacting standards for critical use.

2. Real-Time Freight Visibility

See your shipment’s journey: packing photos, vessel/truck IDs, and constantly refreshed arrival times

3. Industrial-Grade Fastener Protection

- Heavy-Duty Stackable Containers – Reinforced Corner Design.

- Advanced Corrosion Prevention – VCI Bags, Desiccants & Protective Coatings.

- Guaranteed Damage-Free Transit: Custom foam inserts and dividers for mixed fastener shipments

4.Custom-Tailored Shipping Options

- Express Air: Ideal for prototypes or emergency replenishment

- FCL/LCL Ocean Freight: High-volume delivery at lowest landed cost

- Hybrid Routes: Strategic blend of rail, road and sea transport for major project shipments

PRIME’s Edge in Precision Logistics

Work with Prime for managed global fastener logistics that minimize delays, ensure reliable delivery, and guarantee high-quality packaging.

PRIME’s Edge in Precision Logistics

Twelfth:Better Metal Casting Through Advanced Research and Development

Buyer Concern“I don’t just need machined parts — I also need treatment, coating, assembly, and delivery. Can one partner handle everything?”

“Prime goes further than production. We simplify logistics, cut sourcing hassles, and keep you competitive with on-time delivery worldwide.”

1.The Evolution of Metal Casting

Our R&D focuses on next-generation materials to enhance our casting services. We develop lightweight, high-strength solutions for aerospace and automotive industries, plus specialized alloys for extreme environments. By partnering with top institutions, we ensure precise and reliable casting of advanced materials.

2. Enhancing Processes

Smart Mold Development: Embedding sensors for real-time monitoring to maximize mold lifespan and minimize unplanned downtime.

Robotics & AI Integration: Automating handling, transfer, and quality checks to enhance precision and optimize labor efficiency.

Simulation & Predictive Analysis: Leveraging FEA and CFD software to identify and resolve potential defects digitally, before physical production begins.v

3. Environmentally Conscious Production

Lower Operational Costs & Footprint: Our investments in modern, energy-efficient equipment and optimized workflows significantly reduce energy use and costs.

Towards a Zero-Waste Future: We maximize material utilization through rigorous scrap recycling and process refinement, diverting waste from landfills.

Safer for People & Planet: Our commitment to R&D in green chemistry is replacing traditional coatings with safer, low-emission alternatives that protect both worker health and the environment.

4. Custom Metal Casting Services

Leveraging our robust R&D infrastructure, we architect customized casting systems for applications with exceptional demands. We engage with projects involving pioneering techniques, advanced material science, and exacting precision requirements. Our engineering group provides integrative support from initial concept through to full-scale production, effectively translating ambitious designs into manufacturable realities.

PRIME’s Fastener Innovation Edge:

Prime transforms fastener potential through advanced materials, smart manufacturing, and collaborative engineering – delivering tomorrow’s solutions today.

Thirteenth:Vertical Integration: Streamlining Your Supply Chain with Added-Value Services

Simplifying your supply chain by consolidating vendors leads to significant cost savings and greater efficiency for B2B purchasers. At PRIME, we provide a full range of services that transform your casting requirements into a complete, single-source solution. This reduces administrative overhead and supplies parts that are prepared for immediate integration.

Buyer Concern:“Since my parts need heat treatment, coating, and assembly in addition to machining, can one supplier provide an all-in-one solution with speed and reliability?”

“Alongside our CNC machining, PRIME provides tailored finishing, packaging, and subassembly services. With vertical integration and ISO compliance, we deliver components that are consistent, reliable, and production-ready.”

1. Value-Added Machining

- CNC Machining: Unlock design freedom and precision. We use CNC machining to create complex geometries, perfect threads, and hold tolerances that casting cannot, ensuring your part functions exactly as intended.

- Tapping & Reaming: Guarantee perfect fits. Our precision tapping and reaming services ensure that every hole and thread is accurately sized and positioned for reliable assembly and optimal performance in critical applications.

- Grinding: Achieve flawless, high-tolerance surfaces. Our grinding processes provide the superior flatness and precise thickness control required for sealing, bearing, and other high-performance applications.

2. Parts Assembly and Subassembly

- Mechanical Assembly: We build complete, functional units by expertly combining your castings with all necessary components—from springs to seals—saving you time and ensuring perfect compatibility.

- Welding: We create strong, reliable, and permanent joints using the optimal welding process (MIG, TIG, or Spot) for your application, ensuring structural integrity and long-term performance.

- Fastener Insertion: We embed strong, precise threads directly into your castings, providing durable attachment points that are ready for fast assembly and disassembly in the field.

3.Multi-Component Packaging and Customization

- Kitting: Simplify and accelerate your production line. We deliver all parts for an assembly together in one kit, reducing handling and preventing errors.

- Custom Packaging: Reduce damage and shipping costs. Our packaging is engineered to protect your investment during transit and minimize wasted space.

- Labeling & Barcoding: Gain instant traceability and control. Our labeling solutions ensure every part is easily identified and can be seamlessly scanned into your inventory system.

4.Heat Treatment

- Annealing: We soften and stress-relieve parts to make them easier to machine and less likely to warp or crack during fabrication.

- Hardening & Tempering: We make critical components harder, stronger, and more resistant to wear, ensuring they last longer in demanding applications.

5. Contaminant Removal and Edge Conditioning

Ultra-Clean Surfaces for Perfect Results: We guarantee contaminant-free parts to eliminate adhesion failures in painting or coating, ensuring your product’s quality and durability.

Smoother, Safer, High-Performance Parts: Beyond just removing sharp edges, our deburring techniques create uniform radii for reduced wear, improved fluid flow, and a professional, safe-to-handle product.

Fourteenth:Processing technology

Parts for CNC milling

Features

- Machining is performed by rotating the workpiece with fixed cutting tools

- Ideal for producing round parts, shafts, holes, and similar geometries

- Fast processing speed, suitable for mass production

Applications

- Engine parts, shafts, and gears in automotive manufacturing

- Aircraft engine components and landing gear parts

- Bearings, gears, and power transmission parts in machinery

CNC grinding of parts

Features

- Achieves very high surface finish and dimensional accuracy using high-speed rotating abrasive tools

- Suitable for parts with high hardness and complex shapes

- Primarily used for surface finishing to significantly improve part quality

Applications

- High-precision tools such as molds, cutting tools, and bearings

- Automotive engine parts and brake system components

- Surface processing of precision electronic components

- High-accuracy parts in the aerospace industry

CNC turning parts

Features

- Machining is performed by rotating the workpiece while using fixed cutting tools

- Ideal for processing circular parts, shafts, holes, and similar geometries

- High processing speed, well-suited for mass production

- Delivers high precision and excellent surface finish

Applications

- Engine components, shafts, and gears in automotive manufacturing

- Aircraft engine parts and landing gear components

- Bearings, gears, and transmission parts in machinery

- Electronic connectors, housings, and enclosures

CNC Electrical discharge machining (EDM) parts

Features

- Uses electrodes to process materials with high hardness or complex shapes

- Suitable for precision detail machining, though the processing speed is relatively slow

Applications

- Complex molds and cooling channels

- Precision hole machining for aero-engine components

- Automotive gears, cams, and other intricate parts

CNC water jet cutter cutting parts

Features

- Uses high-pressure water, with or without abrasive, to cut various materials including metal, plastic, stone, and glass

- No heat-affected zone, suitable for cutting materials of varying thickness

Applications

- Body cutting and precision part processing in automotive manufacturing

- Stone and tile cutting in the construction industry

- Fine cutting for sculpture and decorative applications

CNC laser marking parts

Features

- Uses a high-intensity laser beam to heat material surfaces to a molten state and removes molten metal with high-speed airflow

- Ideal for cutting sheet metal with smooth edges that require no further processing

- High machining accuracy, suitable for complex shapes and detailed features

Applications

- Automotive shells and interior components

- Steel structures and architectural decorative elements

- Electronic housings and metal components

CNC laser cutting parts

Features

- Marks the surface of materials using a laser beam, including text, patterns, and QR codes

- No consumables required; markings are clear, durable, and suitable for metal, plastic, glass, and more

Applications

- Product identification and QR codes on phones, computers, and electronics

- Marking for medical equipment and surgical tools

- Serial numbers and tracking codes for automotive parts

Fifteenth:Workflow Overview

To guarantee that every metal fastener meets precise customer specifications, we follow a rigorous nine-step quality assurance process, spanning from initial technical review to post-delivery validation

Procedure 1: Conceptual Design and CAD Modeling

Before production begins, our engineering team collaborates closely with customers to ensure every part is designed to meet their exact requirements. Using advanced CAD software, we create precise 3D models and conduct thorough analysis and optimization to guarantee functionality and manufacturability.

Procedure 2:Material Selection

We offer a wide selection of metal materials, including aluminum alloys, stainless steel, copper, and more. Based on the specific requirements of each part, we select the most suitable material to ensure optimal performance, strength, and long-term durability.

Procedure 3: CNC Programming

After selecting the appropriate material, we develop a detailed CNC machining program. With computer numerical control technology, we precisely control the cutting path and depth of each tool to ensure the dimensional accuracy and consistency of every part.

Procedure 4:Processing

Our CNC machine tools execute automated precision machining based on digital programming instructions, performing exact cutting and shaping operations to form complete components. This computer-controlled process ensures consistent dimensional accuracy and detail reproduction without manual intervention, guaranteeing part-to-part uniformity.

Procedure 5:Quality Control

All machined parts undergo stringent quality inspections using precision measuring equipment to thoroughly verify dimensions, tolerances, and surface finishes, ensuring complete compliance with design specifications.

Procedure 6:Post-Processing and Surface Finishing

To meet specific application needs, we offer comprehensive post-processing options including mechanical polishing, powder coating, anodization, and other specialized surface treatments. These finishing processes simultaneously enhance both aesthetic qualities and functional performance – significantly improving corrosion protection and wear characteristics while achieving the desired visual appearance.

Procedure 7: Final Inspection and Packaging

Upon successful quality verification, all CNC-machined components undergo protective packaging using industrial-grade materials tailored to part specifications and shipping requirements

Procedure 8: Delivery of finished product

After completing all inspections and post-processing, the castings are finished and ready for delivery to customers or assembly into final products.

Sixteenth:What Our Clients Said

Maximilian

Product Manager, PM

“Die Zusammenarbeit mit Prime hat unseren Fertigungsprozess erheblich rationalisiert. Ihre Präzision und schnellen Durchlaufzeiten waren ein Schlüsselfaktor für unseren Produktionserfolg.”

Kenta Sato

Purchasing manager,UACJ

“プライムとの協力により、製造工程が大幅に合理化されました。彼らの精度と迅速な納期は、私たちの生産成功の重要な要因となっています”

Elias Söderberg

Production Supervisor,Sandvik AB

“Att arbeta med Prime har avsevärt effektiviserat vår tillverkningsprocess. Deras precision och snabba handläggningstider har varit en nyckelfaktor för vår produktionsframgång.”

Seventeenth:Manufacturing & Packing at A Glance

Eighteenth:In Summary

Selecting the right custom cylinder component supplier goes far beyond comparing unit prices. This guide has covered key considerations in engineering, machining, and finishing of precision parts like threaded lock rings, welded neck collars, and lightweight aluminum retaining rings. Long-term success depends on choosing a partner who supports your innovation and production goals.service life.

Essential Insights for Procurement

- Manufacturing Expertise: Ensure your supplier masters cold heading, thread rolling, and CNC finishing for strength and precision.

- Reliable Quality Systems: ISO-certified processes, full dimensional inspection, and material traceability help reduce risk and defects.

- More Than Unit Price: Evaluate tool life, assembly-readiness, delivery time, and engineering service — not just per-piece cost.

- Collaborative Engineering: Suppliers who provide early design support and DFM insight help avoid future failure points.

- Scalable Global Service: Partners with worldwide reach and local responsiveness prevent customs delays and support stable growth.

PRIME’s Competitive Edge

With over 30 years of experience, PRIME supplies custom fasteners for sectors including automotive, energy, construction, and machinery. From complex bolts to high-performance screws, our advanced facilities and certified quality systems ensure consistent, compliant output.

We go beyond manufacturing — providing design review, material selection, custom coatings, and full packaging support. From prototype to mass production, PRIME is your fastener sourcing partner.

Borderless Logistics, Grounded Trust

With optimized export packaging, streamlined customs documentation, and a proactive sales team, we guarantee timely deliveries and smooth international transactions.

From single-product orders to full-scale global deployments, PRIME provides tailored fastener solutions backed by flexible, scalable support—wherever your operations take you.

Receive a competitive quote within 24 hours

With Prime, you’ll receive a competitive quote within 24 hours — helping you save valuable time in sourcing decisions. Rapid response means you can compare costs, plan budgets, and accelerate your project schedule with confidence.

Simply Customize Metals

Finding top-quality custom metal parts doesn’t have to be complicated. At Prime, we guide you through it in three easy steps:

Three Decades of Trusted Production Experience, Delivered from Our Own Facilities

Custom-Designed Components Engineered for Your Specific Applications

Worldwide Delivery Network with End-to-End Logistics Services

Fast and Transparent Quotes with No Hidden Conditions

Your Designs and Information Stay Fully Confidential — Guaranteed

After you confirm the design and pricing, we’ll start production and manage the shipping—making sure everything arrives on time.

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.