CNC Plastic Parts Tolerances: Your Complete Engineer’s Guide (Charts Included)

Your design for a new ABS enclosure is perfect. The CAD model shows every snap-fit and mounting boss aligning precisely. But when the first machined prototypes arrive, nothing fits.

Achieving tight tolerances in CNC plastic parts requires understanding that plastics are not stable like metals. Factors like thermal expansion, moisture absorption, and internal material stress fundamentally change how a part must be designed, toleranced, and inspected.

I've seen millions of dollars wasted over the years because of a single, flawed assumption: that a tolerance that works for aluminum will work for Delrin®. A few years back, a client sent us a drawing for a medical device component made from polycarbonate. They had specified a ridiculously tight tolerance of ±0.0005 inches (about ±0.013 mm) on a long, thin feature. I called the engineer immediately. I explained that while we could hit that number in our temperature-controlled QC lab right after machining, the part would be out of spec by the time it reached his desk in a different climate due to thermal expansion alone. We worked together to relax the tolerance to a more realistic ±0.002 inches (±0.05 mm), which was more than sufficient for the part's function. This saved them over 60% on the part cost and eliminated a future assembly-line headache.

I've seen millions of dollars wasted over the years because of a single, flawed assumption: that a tolerance that works for aluminum will work for Delrin®. A few years back, a client sent us a drawing for a medical device component made from polycarbonate. They had specified a ridiculously tight tolerance of ±0.0005 inches (about ±0.013 mm) on a long, thin feature. I called the engineer immediately. I explained that while we could hit that number in our temperature-controlled QC lab right after machining, the part would be out of spec by the time it reached his desk in a different climate due to thermal expansion alone. We worked together to relax the tolerance to a more realistic ±0.002 inches (±0.05 mm), which was more than sufficient for the part's function. This saved them over 60% on the part cost and eliminated a future assembly-line headache.

¿Por qué las tolerancias para plásticos son diferentes a las de los metales?

Engineers who spend their careers with steel and aluminum are often surprised when their first plastic parts fail inspection. Why can't you hold the same +/- 0.025 mm tolerance on a nylon part that you can on a steel one?

Plastics are fundamentally "alive" compared to metals. Their dimensions actively change with temperature and humidity, and they contain internal stresses from their manufacturing process that can cause warping after machining.

El Coeficiente de Expansión Térmica (CTE)

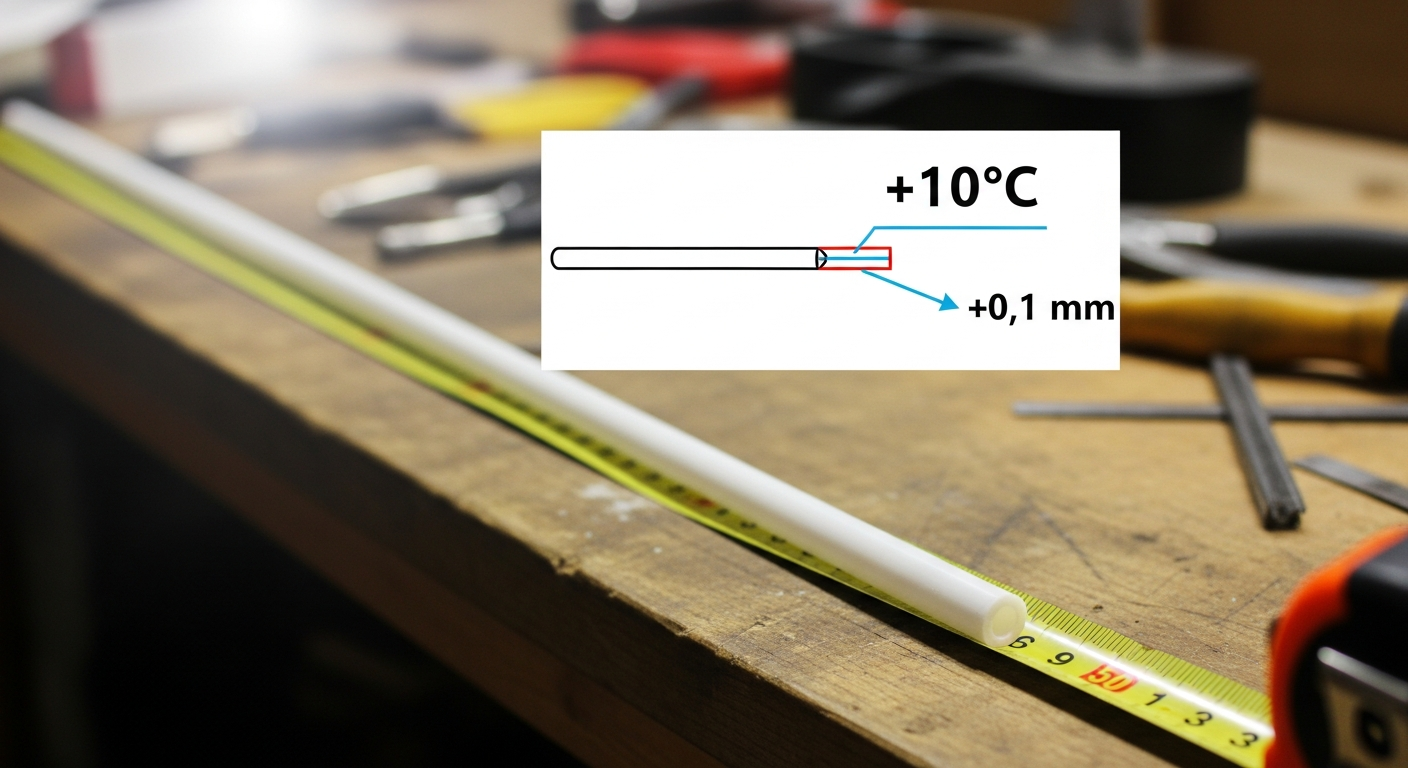

This is the number one reason for tolerance issues. Plastics expand and contract with temperature changes at a rate 5 to 10 times greater than metals. A part that is perfectly in-spec in our 20°C workshop could be significantly larger or smaller in your 30°C facility.

| Material | Thermal Expansion Coefficient (μm/m·°C) | Relative Expansion vs. Steel |

|---|---|---|

| Steel | ~12 | 1x (Baseline) |

| Aluminum | ~23 | ~2x |

| Acetal (Delrin®) | ~85 | ~7x |

| Nylon 6/6 | ~90 | ~7.5x |

| ABS | ~100 | ~8.3x |

La Absorción de Humedad y la Estabilidad Dimensional

Many common plastics, especially Nylons and polyamides, are hygroscopic – they absorb water from the air. This absorption causes the material to swell, changing its dimensions. A Nylon part machined in a dry environment can grow significantly and go out of tolerance if it's later used in a humid location.

Las Tensiones Internas del Material

The process of extruding plastic into rods and sheets leaves internal stresses locked within the material. When we start machining away the surface, we can release these stresses unevenly, causing the part to warp, bow, or twist. This is especially true for parts with a lot of material removal or with thin walls.

Comment le choix du matériau plastique affecte-t-il les tolérances?

You know you need a plastic part, but the catalogue lists dozens of options: ABS, Polycarbonate, PEEK, Ultem®. Does it matter which one you choose for your tolerance needs?

Absolutely. The inherent properties of each plastic—its hardness, stability, and whether it's filled with additives like glass—directly dictate the level of precision and the tightest achievable tolerance for your component.

Plastiques tendres vs. Plastiques durs

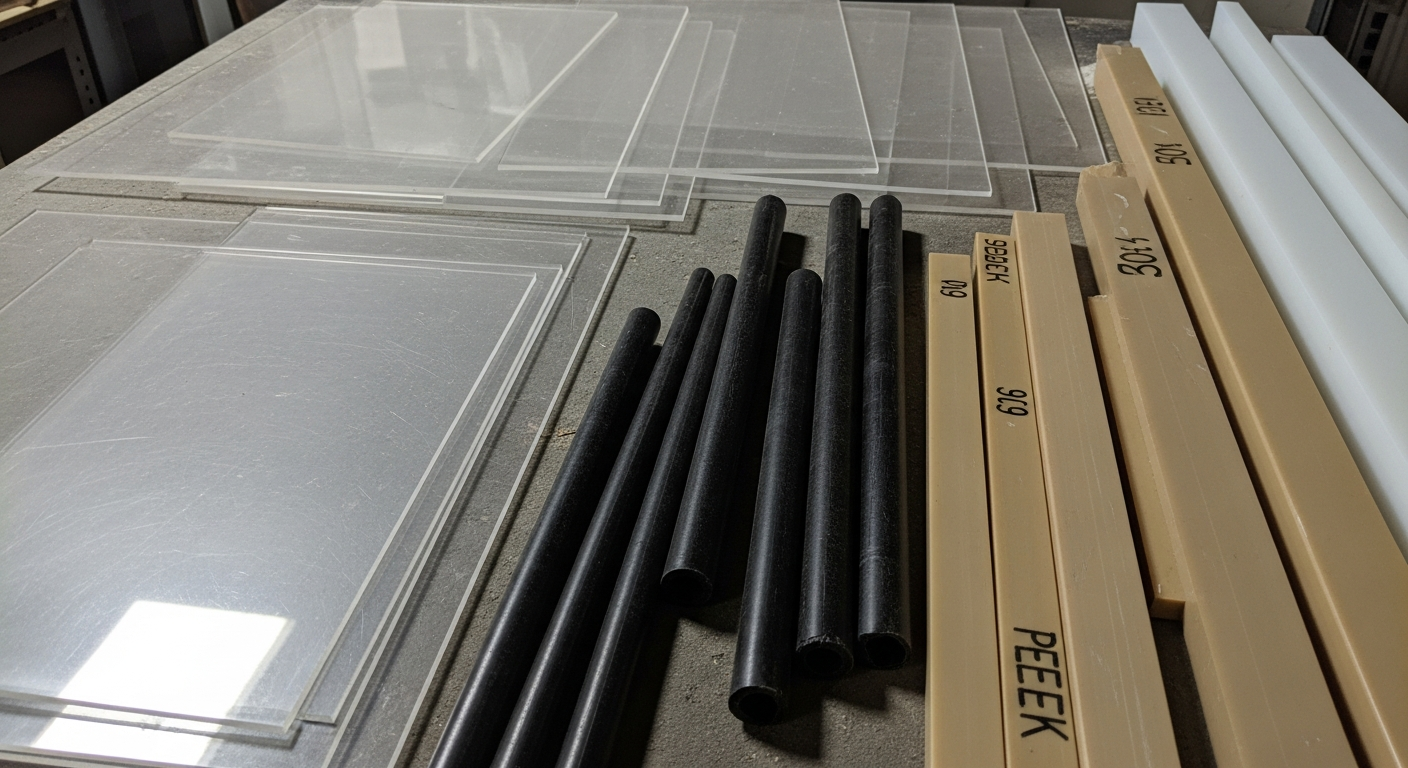

Softer, more flexible plastics like Polypropylene (PP) or LDPE are notoriously difficult to machine to a high precision. The material can deflect away from the cutting tool, and it's prone to creating a poor surface finish. Hard, rigid, and stable plastics like PEEK or Acetal (Delrin®) behave more like metal during machining, allowing for much tighter tolerances. We create many of our high-precision [custom CNC parts](https://www.hrscrew.com/precision-machining-news-corner/the-advantages-of-custom-cnc-machined-parts) from these engineering-grade plastics.

Plastiques chargés vs. Non chargés

"Filled" or "reinforced" plastics have additives mixed in, most commonly glass fibers (GF). Adding 30% glass fiber to Nylon (Nylon 6/6 30% GF) dramatically increases its strength, stiffness, and dimensional stability. This makes it less prone to moving from temperature or moisture changes, allowing for tighter tolerances than its unfilled counterpart. However, glass-filled materials are very abrasive and require special tooling to machine.

Tableau de comparaison pratique des matériaux

Here's a quick guide from my factory floor experience on what to expect. For an in-depth look, a great resource is the online material database from a supplier like Curbell Plastics.

| Plastic Material | Machinability & Stability | General Achievable Tolerance | Cost Index |

|---|---|---|---|

| ABS | Good / Fair Stability | ±0.1 mm (Commercial) | $ |

| Acetal (Delrin®) | Excellent / Good Stability | ±0.05 mm (Precision) | $$ |

| Nylon 6/6 | Good / Poor Stability (Moisture) | ±0.15 mm (Needs care) | $$ |

| Polycarbonate | Very Good / Good Stability | ±0.075 mm (Precision) | $$$ |

| PEEK | Excellent / Excellent Stability | ±0.025 mm (High Precision) | $$$$$ |

Quais são as tolerâncias de usinagem CNC padrão para plásticos?

When you don't specify a tolerance on a feature, what should you expect to receive? Is there a universal standard that all machine shops follow?

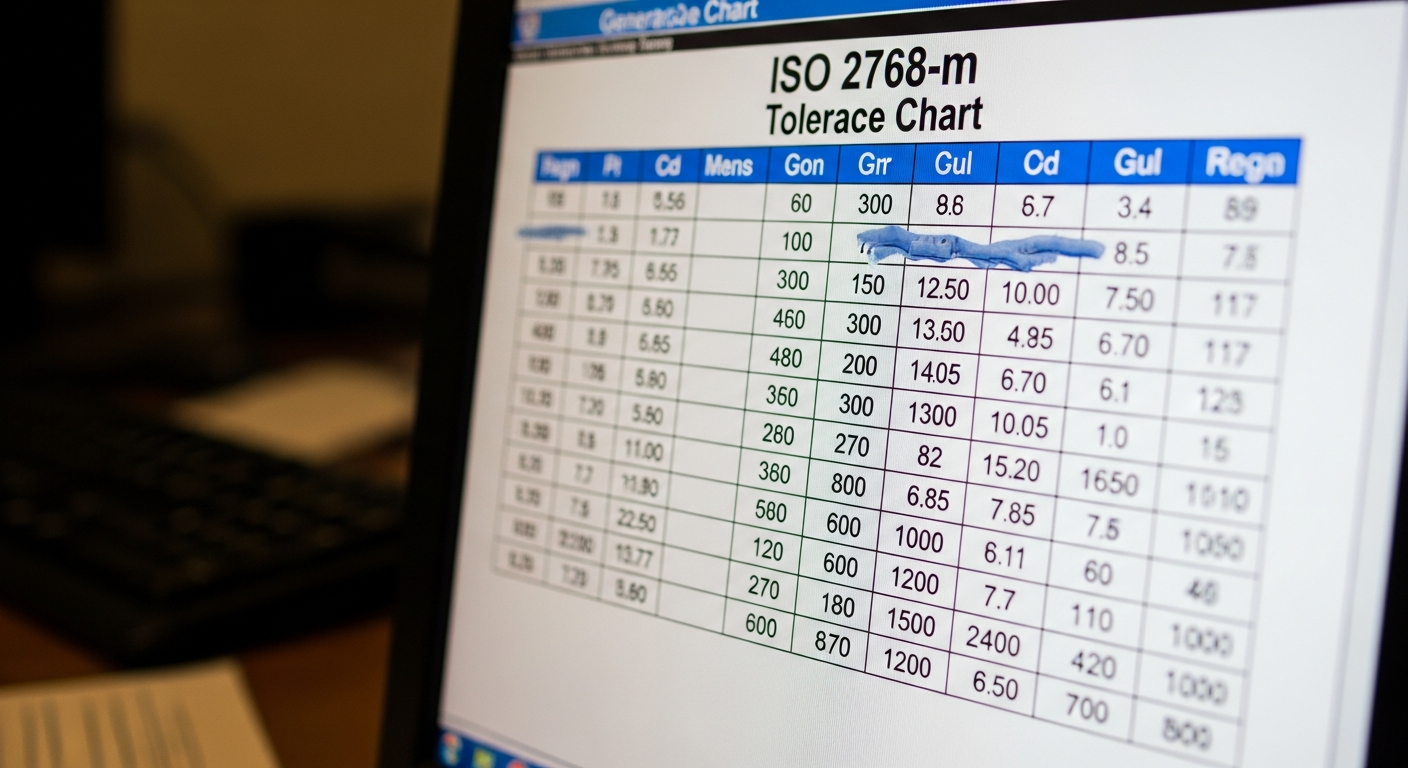

While there's no single universal standard just for plastics, many shops, including ours, use the general machining standard ISO 2768 as a starting point. However, this must be applied with engineering judgment based on the material and part geometry.

Normas de tolerância geral como a ISO 2768

ISO 2768 provides different tolerance classes: fine (f), medium (m), coarse (c), and very coarse (v). For most non-critical features on plastic parts, we default to ISO 2768-m (medium). This provides a good balance of precision and cost-effectiveness. Specifying "fine" for everything is a common mistake that dramatically increases the cost for no functional benefit.

Tolerâncias comerciais vs. Tolerâncias de precisão

As a buyer, it's useful to think in these two buckets:

- Commercial Tolerance (e.g., ±0.1 mm to ±0.25 mm): This is the standard for most features. It can be achieved with standard setups and tooling, keeping costs low. Most general-purpose plastic parts fall into this category.

- Precision Tolerance (e.g., < ±0.1 mm): This is for critical features like bearing bores, press-fit diameters, or mating surfaces. Achieving this requires more careful setups, slower machining speeds, special tooling, and more intensive post-machining inspection, which all add to the cost.

Uma tabela de referência de tolerâncias

This is a simplified table we use to guide our customers. It's not a substitute for a proper engineering drawing, but it's a good starting point for a conversation.

| Dimension Range (mm) | Commercial Tolerance (±mm) | Precision Tolerance (±mm) |

|---|---|---|

| 0.5 - 6 | 0.10 | 0.05 |

| 6 - 30 | 0.15 | 0.06 |

| 30 - 120 | 0.20 | 0.08 |

| 120 - 400 | 0.30 | 0.10 |

كيف يؤثر تصميم الجزء على التفاوتات الممكنة؟

You've chosen the right material and specified realistic tolerances. Can you still run into problems? Yes, if the part is not designed for manufacturability.

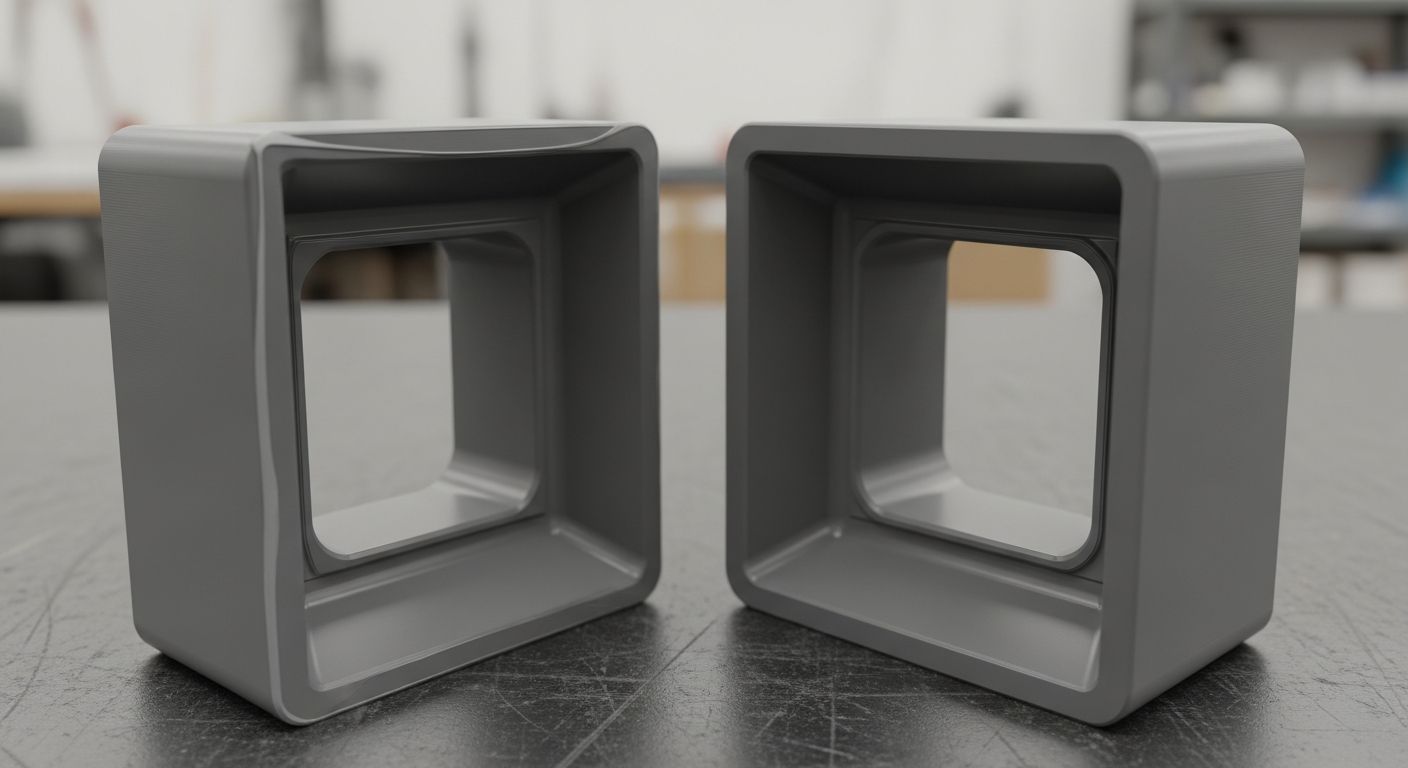

Poor design features are a primary cause of tolerance failures in plastic parts. Inconsistent wall thicknesses create warping, and sharp internal corners create stress points that are impossible to machine accurately.

أهمية سماكة الجدار المتسقة

This is the golden rule of plastic part design. When you have a thick section next to a thin section, the part cools and shrinks unevenly after machining, causing internal stresses that lead to warping. Keep a uniform wall thickness throughout your part wherever possible.

تجنب الزوايا الداخلية الحادة

A CNC machine uses a round cutting tool. It cannot create a perfectly sharp internal corner. Attempting to do so requires very small tools or secondary operations like EDM, which adds enormous cost. Always design your internal corners with a radius, ideally one that is larger than 1/3 of the wall thickness. This not only makes the part easier and cheaper to machine but also makes it much stronger, as sharp corners are natural stress concentrators.

موقع الميزات وتأثيره على الدقة

The location of features matters. A hole in the middle of a large, stable block of plastic is easy to position accurately. The same hole on the end of a long, thin, cantilevered feature is very difficult to hold a tight positional tolerance on, as the feature itself may flex during machining.

About the Author

My name is Kevin. I founded Prime Metals in 1993 after a long career as a buyer for large industrial companies in the US. I know the frustrations of dealing with suppliers who don't understand the materials they work with. I built this company to be different—to be a true technical partner who helps you make the right decisions from the very start.

Frequently Asked Questions (FAQs)

What is the tightest possible tolerance for a CNC machined plastic part?

Under ideal conditions (stable material like PEEK, small part, temperature-controlled environment), it's possible to achieve tolerances as tight as ±0.001 inches (±0.025 mm). However, this is extremely expensive and should only be specified when absolutely necessary.

How does temperature in the final application affect my plastic part?

You must account for it in your design. If a 100 mm Delrin rod will operate at 50°C (a 30°C rise from room temp), it can be expected to grow by: 100 mm 85 µm/m·°C 30°C = ~0.25 mm. Your design tolerances must accommodate this change. The Wikipedia page for Acetal resin lists many of these key physical properties.

Does the color of the plastic affect its machinability or tolerances?

Generally, no. The base pigments used for coloring do not significantly alter the mechanical or thermal properties of the plastic. However, some additives for special properties (like UV resistance or conductivity) can sometimes have a minor effect on machinability.

From Drawing to Reality

Specifying tolerances for plastic parts is a dialogue between design intent and manufacturing reality. Over-tolerancing drives up cost, while under-tolerancing leads to functional failures. The key is to work with a manufacturing partner who understands the nuances of these unique materials.

Let our team review your design and help you define tolerances that are both functional and cost-effective.