TIG vs MIG Welding: Which Process Is Best for Industrial Fabrication?

You need a welded assembly, but the quotes you're getting vary wildly. One supplier uses MIG, another TIG. The choice seems technical, but it directly impacts your project's cost, timeline, and final quality.

For industrial fabrication, MIG welding is the best choice for speed, automation, and cost-efficiency on steel. TIG welding is superior for precision, high-purity welds, and visual appearance, especially on aluminum and stainless steel.

In our factory, the welding and assembly services department is where individual components become a final product. We see every day how choosing the right process is not just a technical detail—it's a critical business decision. I've seen projects go over budget because of a slow, overly precise process and others fail quality checks due to a fast but messy one. Let's break down the real-world differences so you can make an informed choice.

What’s the Fundamental Difference in How TIG and MIG Work?

To a buyer, a weld is a weld. But to an engineer, the processes are worlds apart. Using the wrong one is like using a sledgehammer for a task that needs a surgical scalpel.

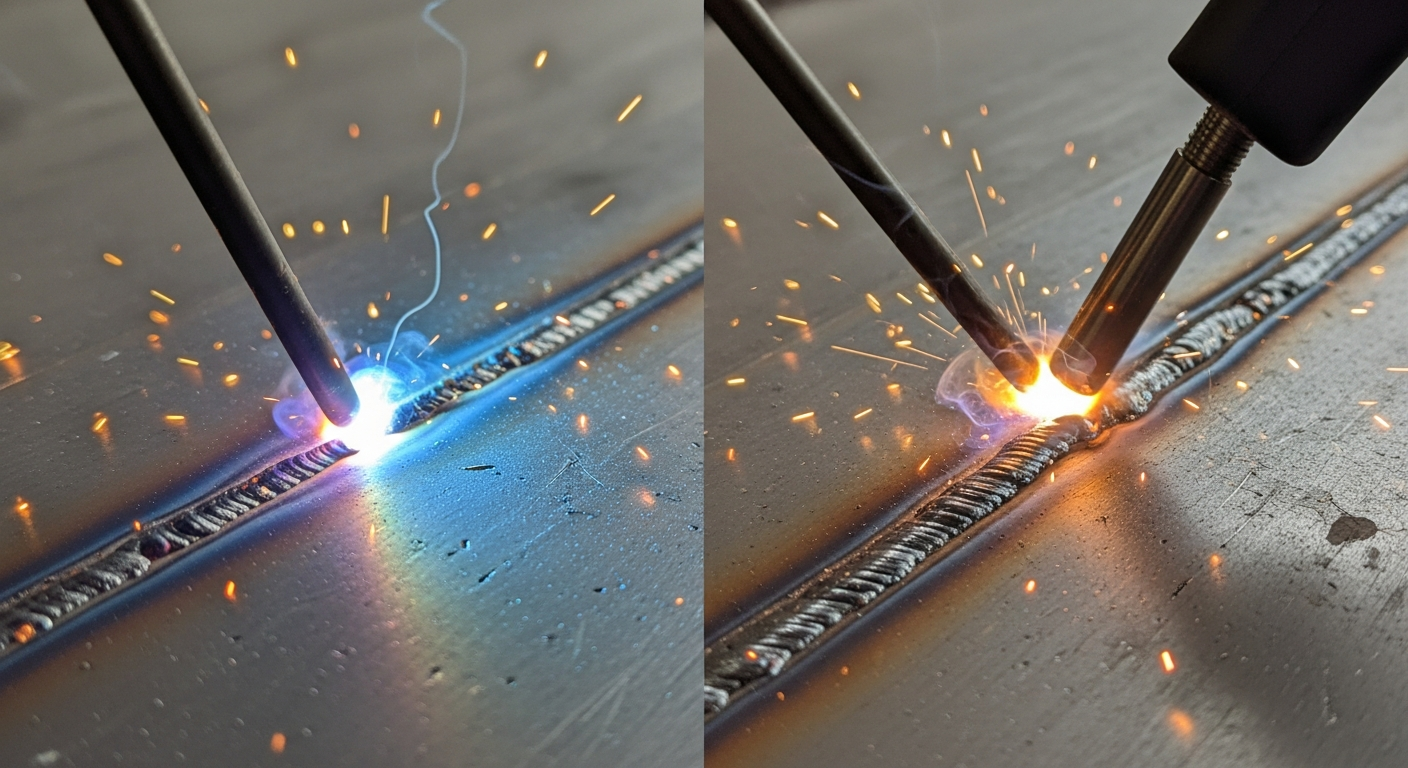

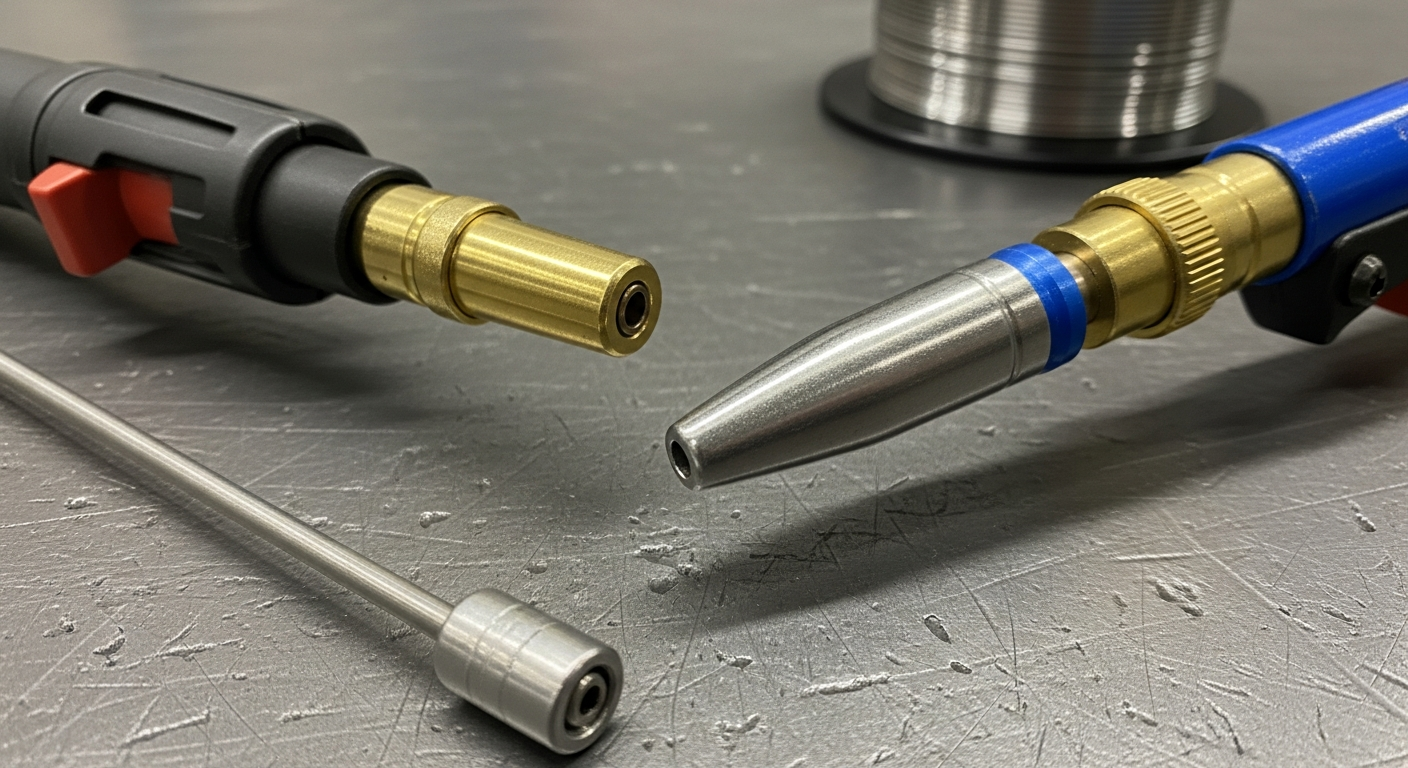

The core difference is the electrode. MIG (Metal Inert Gas) uses a continuously feeding wire that serves as both the electrode and the filler metal. TIG (Tungsten Inert Gas) uses a non-consumable tungsten electrode and a separate, hand-fed filler rod.

The TIG Process: The Surgeon's Scalpel

Think of TIG welding as a two-handed, highly controlled operation. One hand holds the TIG torch, which creates a very precise arc from the tungsten electrode. The other hand carefully dips a filler rod into the molten puddle. The welder often uses a foot pedal to finely control the amperage (heat), similar to a gas pedal. This meticulous process offers unparalleled control, resulting in extremely clean and precise welds.

The MIG Process: The Production Powerhouse

MIG welding is a much simpler, one-handed "point-and-shoot" process. The operator pulls a trigger, and the machine automatically feeds the wire electrode at a constant speed while shielding gas flows. It's designed for speed and simplicity. The operator focuses on maintaining the correct travel speed and gun angle, making it much easier to learn and far faster in production.

Core Process Comparison

| Feature | TIG (Gas Tungsten Arc Welding - GTAW) | MIG (Gas Metal Arc Welding - GMAW) |

|---|---|---|

| Electrode | Non-consumable tungsten | Consumable wire |

| Filler Metal | Separate, manually fed rod | Integrated into the electrode wire |

| Control | High (foot pedal for heat control) | Medium (set on the machine) |

| Complexity | High (two-handed coordination) | Low (one-handed "point and shoot") |

When Does Speed Matter More Than Precision?

Your project is behind schedule, and your fabrication partner is moving at a snail's pace. The beautiful welds they are producing don't matter if you miss your market window.

Speed matters most in high-volume production of structural parts where cost-per-unit and lead time are the primary drivers. MIG welding is a faster process, often reducing welding time by 50-75% compared to TIG for the same joint.

MIG Welding for Production Volume

MIG is the champion of deposition rate—the amount of metal it can lay down in a given time. This makes it the clear choice for our large-scale production runs, especially when we're joining multiple stamping parts to create industrial frames or enclosures. Longer, continuous welds on thicker steel are where MIG shines, turning hours of TIG work into minutes.

TIG Welding for Critical, High-Precision Joints

Sometimes, speed is the enemy of quality. For mission-critical components, like a custom fitting made from one of our CNC parts, the integrity of that one weld is paramount. The slow, deliberate nature of TIG welding allows the operator to ensure perfect fusion and penetration, which is why it's mandated in industries like aerospace, nuclear, and high-performance automotive.

The Cost Equation: Labor vs. Quality

The impact on your budget is direct. Time is money, and labor is the biggest cost in any welding job. A process that is four times faster, like MIG, directly translates to a lower labor cost per component. Your decision must balance the need for speed and cost-savings against the required level of precision and weld purity.

Which Process Produces a Stronger, Cleaner Weld?

You've received a batch of welded parts. They seem strong, but they are covered in little balls of metal spatter and the weld bead is inconsistent. This poor finish requires extra work and reflects badly on your product.

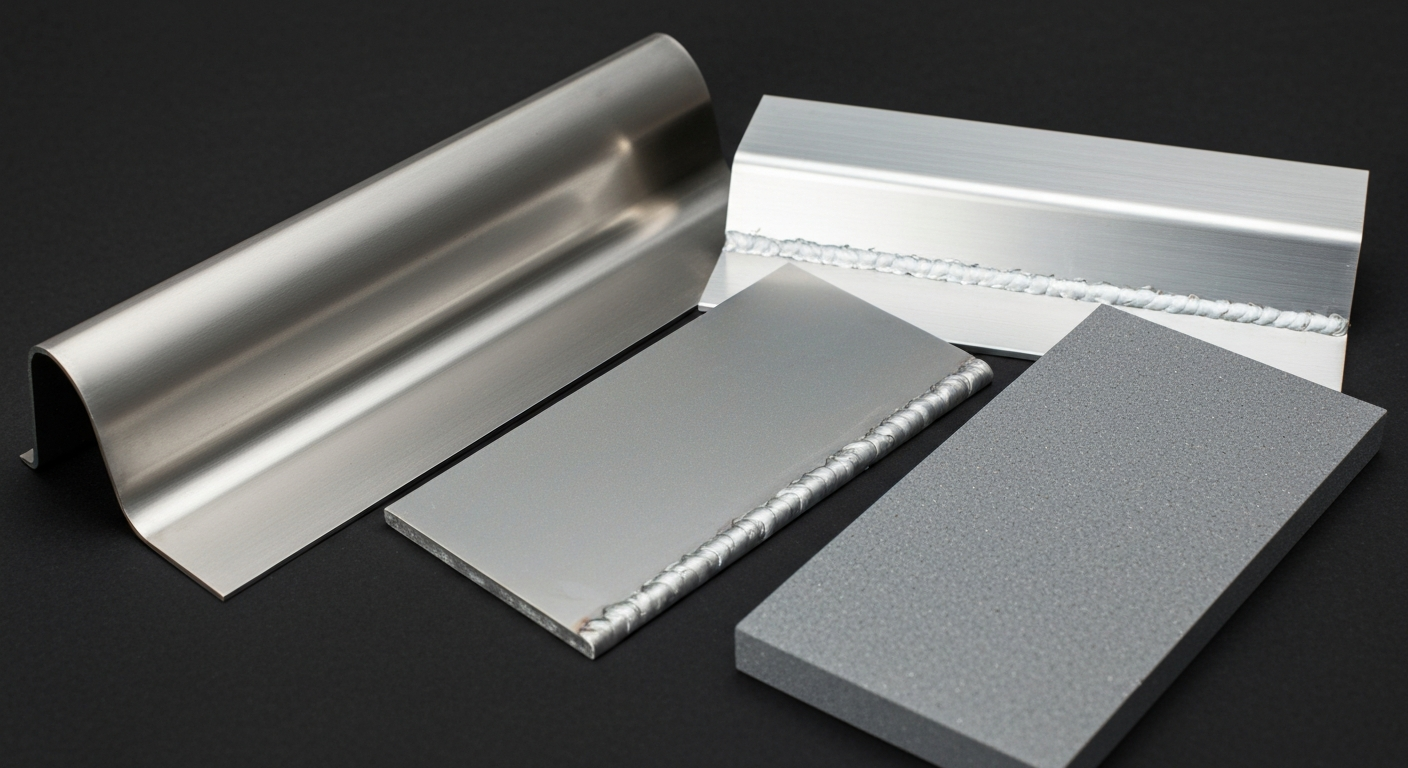

TIG welding produces the cleanest, most aesthetically pleasing welds with virtually no spatter. While a properly executed weld from either process is immensely strong, TIG's purity and control often result in a weld of higher metallurgical quality.

The Aesthetics and Purity of a TIG Weld

A TIG weld is the hallmark of craftsmanship. The characteristic "stack of dimes" look is not just for show; it indicates a clean, consistent, and pure weld pool. Because there is no spatter, TIG-welded parts require no post-weld grinding. This is essential for consumer-facing products, food-grade stainless steel, and parts that need a perfect surface for painting or plating.

Strength and Weld Integrity

According to the American Welding Society (AWS), a properly designed and executed weld from either MIG or TIG should result in a joint that is stronger than the base metal itself. The failure should happen next to the weld, not in it. However, the TIG process, with its clean arc and separate filler, significantly reduces the likelihood of contaminants or porosity being trapped in the weld, creating a purer joint.

The MIG Spatter Problem

MIG welding, especially using a cost-effective Argon/CO2 gas mix, inherently produces spatter. These small beads of molten metal stick to the workpiece and must be ground or scraped off. This adds an entire secondary operation to the fabrication process, increasing labor time and cost.

How Does Material Type Dictate Your Welding Choice?

You tried to use your standard steel welding setup for a new aluminum project, and the results are a disaster. The welds are weak, brittle, and full of soot.

MIG is the workhorse for carbon steel. TIG is the master of versatility, providing the control needed for challenging metals like aluminum, stainless steel, magnesium, and titanium. Using the right process for the material is non-negotiable.

TIG's Mastery Over Reactive Metals

Aluminum is a perfect example. It instantly forms a tough, high-melting-point oxide layer on its surface. A specialized TIG machine with an AC (Alternating Current) setting creates a "cleaning action" that blasts away this oxide layer before depositing the filler metal, which is essential for a sound weld. TIG's precise heat control is also critical for stainless steel to prevent overheating, which can ruin its corrosion-resistant properties.

MIG's Strength in Steel Fabrication

For mild and carbon steel, MIG welding is the undisputed king of efficiency. The process is robust, fast, and highly tolerant of slight variations in fit-up. While specialized MIG processes exist for aluminum (known as "spool gun" MIG), they are typically used for thicker sections where speed is more important than the pristine appearance provided by TIG.

Process Selection Guide by Material

| Material Application | Recommended Process | Key Reason |

|---|---|---|

| Thick Steel Structures | MIG | Speed, high deposition rate, and cost-effectiveness. |

| Thin-Gauge Stainless Steel | TIG | Precision heat control to prevent warping and discoloration. |

| Aluminum Fabrication | TIG (AC) | Oxide layer cleaning and superior bead appearance. |

| Custom Screws & Fasteners | N/A (Formed) | Welding is not typically used for fastener production. |

What Are the True Costs and Skill Requirements for Each Process?

You've budgeted for a welding project, but the final invoice is much higher. The hidden costs of operator skill, setup time, and consumables were never considered.

MIG welding has a lower barrier to entry: the equipment is less expensive, and the learning curve is much faster. TIG welding is a true craft, requiring more expensive machinery and highly skilled—and therefore highly paid—welders.

The Operator Skill Gap

This is the single biggest cost factor. We can train a new employee to lay down a structurally sound MIG weld in a matter of hours. Becoming a proficient TIG welder, capable of passing an x-ray quality test, can take years of dedicated practice. This vast difference in skill level is directly reflected in labor costs.

Equipment and Consumable Costs

A basic industrial MIG setup is significantly cheaper than a professional AC/DC TIG welder with all the necessary features. While MIG consumables (wire, tips, gas) are used up faster, the sheer speed of the process usually results in a lower cost per inch of weld. You can find more detail on the process in this Wikipedia article on Gas metal arc welding.

How We Leverage Both at Prime Metals

In adherence with our ISO 9001 certified quality system, we use the right tool for every job. Our production lines use semi-automated MIG welders for structural assemblies to ensure speed and consistency. In our custom fabrication cell, our most experienced artisans use TIG to create flawless assemblies for high-end industrial and medical clients.

About the Author

My name is Kevin. I established Prime Metals in 1993, bringing my decades of experience as a buyer in the US to the manufacturing floor. I built this company to be a partner, not just a supplier. We believe that understanding the "why" behind every process, from welding to finishing, is the key to delivering products that are not just made to spec, but made for success.

Frequently Asked Questions (FAQs)

Is a TIG weld stronger than a MIG weld?

No. When performed correctly according to a qualified procedure, both TIG and MIG can produce welds that are stronger than the base materials being joined. TIG is often considered higher quality due to its purity, but strength is comparable.

Can you TIG weld without a filler rod?

Yes. This is called an "autogenous" weld. It is used to fuse two tightly fitting pieces of metal together using only the heat of the arc to melt and join the parent materials. This is common on thin-gauge stainless steel tubing.

For a beginner, is MIG or TIG easier to learn?

MIG is overwhelmingly easier to learn. The one-handed operation and automated wire feed allow a beginner to create a functional weld very quickly. TIG requires coordinating two hands and a foot, a much more difficult skill to master.

The Right Process for the Right Product

The TIG vs. MIG debate isn't about which is "better"—it's about which is right for your application. The decision hinges on a balance of speed, cost, material, and the required level of quality and precision.

Partner with an expert who knows the difference. We can review your design and help you select the most effective and efficient welding process to ensure your project's success.