From Polymer to Product: How Are Industrial Plastic Components Manufactured?

You have a brilliant design for a new product, but how do you turn that digital file into a million identical, high-quality plastic parts? The path is filled with technical choices that can make or break your project's budget and timeline.

Industrial plastic parts are primarily made using injection molding. This process involves melting plastic pellets and injecting the molten material at high pressure into a custom-made metal mold, where it cools and solidifies into the final part shape.

At Prime Metals, while our name speaks to our deep roots in metalworking, our clients rely on us for complete assemblies. This means we've spent decades mastering the art and science of producing high-precision plastic parts. I've learned that the journey from a simple polymer pellet to a finished product is a game of precision engineering. One small misstep at the start can lead to major failures down the line. Let me walk you through how it's done right.

How Do You Turn a Design into a Manufacturable Part?

You have a perfect 3D model, but will it actually work in a real-world manufacturing process? A design that looks great on screen can be incredibly expensive or even impossible to produce.

The critical first step is a Design for Manufacturability (DFM) analysis. This is an engineering review that optimizes the part's design for the specific manufacturing process, preventing defects, reducing costs, and speeding up production before any steel is cut.

Wall Thickness Consistency

The most fundamental rule in plastic part design is maintaining a uniform wall thickness. If one area is much thicker than another, it will cool slower. This differential cooling causes the part to shrink unevenly, leading to ugly cosmetic defects like "sink marks," or internal stresses that can cause the part to warp and fail. We analyze the model to identify and correct these potential problem areas.

The Importance of Draft Angles

Imagine trying to pull a perfectly straight-sided cup out of a mold; the friction would make it stick. A "draft angle" is a tiny taper, typically 1-3 degrees, applied to the walls of the part parallel to the direction of mold separation. This small angle prevents the part from scraping against the mold as it's ejected, ensuring a clean release and a smooth surface finish. Forgetting draft is one of the most common and costly design mistakes.

Using Radii to Manage Stress

Sharp internal corners are weak points. They create "stress concentrations" where forces are focused, making the part prone to cracking under load. Adding a smooth, rounded corner (a "radius" or "fillet") distributes these stresses over a wider area, dramatically increasing the part's strength and durability. This also helps the molten plastic flow more easily into the mold. A good DFM process, like the one we detail in our PPAP reports, reviews every corner.

How Do You Choose the Right Plastic for the Job?

Your part needs to be strong, heat-resistant, and cost-effective. With thousands of available plastics, picking the wrong one means your product could melt, crack, or fade in its intended environment.

Choosing the right plastic requires balancing three key factors: the mechanical requirements (strength, flexibility), the operational environment (heat, UV, chemical exposure), and the target piece price. This decision is a collaborative effort between the client and the manufacturer.

Commodity vs. Engineering Plastics

Plastics are broadly grouped into two tiers. Commodity Plastics (like Polypropylene, Polyethylene) are inexpensive and easy to process, making them ideal for everyday items like containers and packaging. Engineering Plastics (like ABS, Polycarbonate, Nylon, PEEK) offer superior mechanical and thermal properties. They are stronger, more rigid, and can withstand higher temperatures, which is why we use them for industrial components like gears, housings, and structural parts. As explained by sources like Wikipedia, the performance justifies the higher cost.

The Role of Additives and Fillers

You can customize a plastic's properties with additives. Need more strength and stiffness? We can use a "glass-filled" nylon, where tiny glass fibers reinforce the polymer matrix. Does the part need to survive outdoors? A UV inhibitor additive will prevent it from becoming brittle in the sun. We can also add colorants, flame retardants, and other modifiers to meet your exact specifications.

Matching Material to Your Application

| Plastic Type | Key Characteristics | Common Industrial Uses | Cost Tier |

|---|---|---|---|

| ABS | Good impact strength, easy to process, rigid | Electronic enclosures, protective covers, pipe fittings | Low |

| Polycarbonate (PC) | Excellent impact strength, transparent, rigid | Safety shields, lenses, machine guards, medical devices | Medium |

| Nylon (PA66) | High wear resistance, strong, good chemical resistance | Gears, bearings, bushings, automotive components | Medium |

| PEEK | Extreme heat and chemical resistance, very strong | Aerospace parts, medical implants, pump components | Very High |

What Goes into Creating the Mold for Injection Molding?

You've approved the design and selected the material. Now comes the most critical and expensive upfront investment: creating the tool that will form your parts.

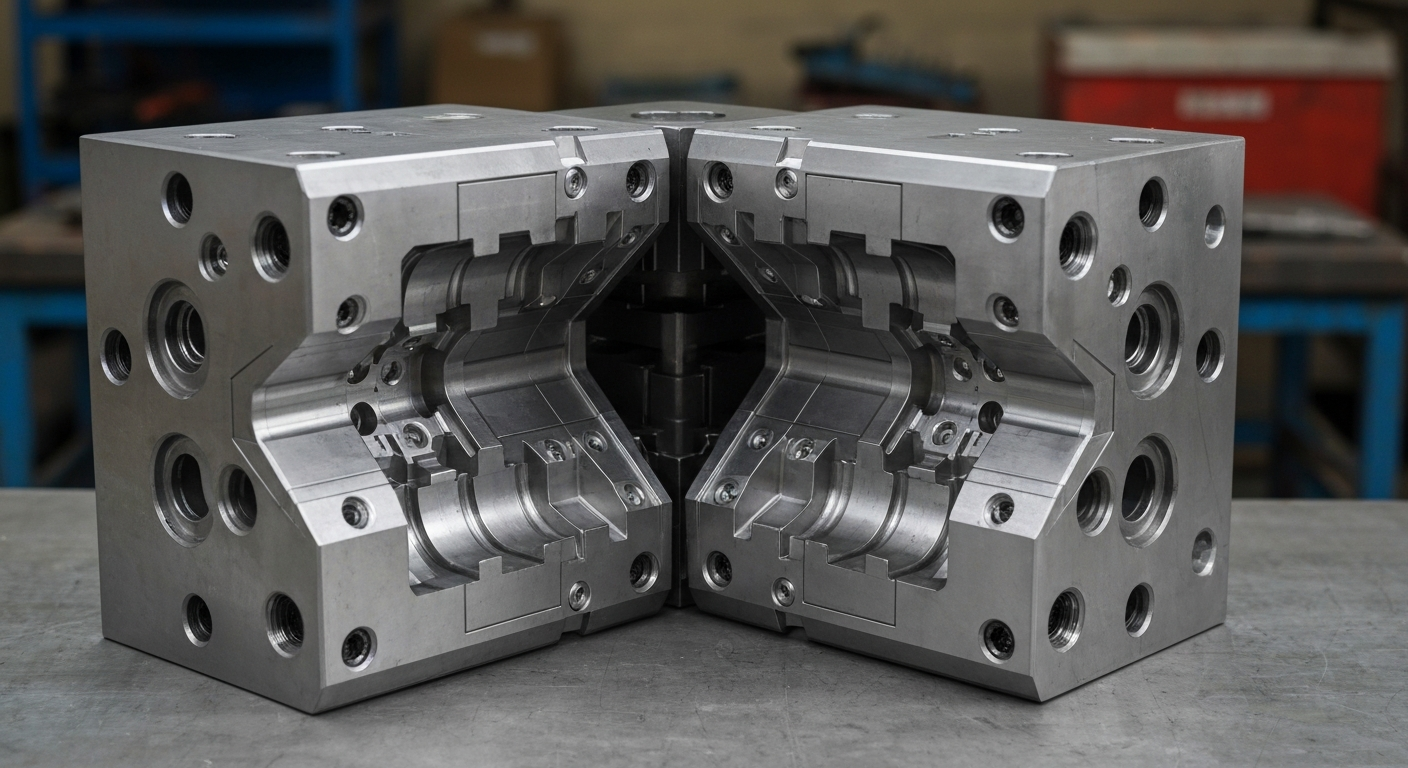

An injection mold is a high-precision tool, machined from hardened steel, that forms the cavity into which molten plastic is injected. Its complexity and durability directly impact the quality and consistency of the final parts.

The Core and Cavity

At its simplest, a mold has two halves. The cavity is the "female" half that typically forms the outer, cosmetic surface of the part. The core is the "male" half that forms the inner features. When these two halves are clamped together under immense pressure, the space between them creates the exact shape of the part. Making these with precision is where our expertise in [CNC Machining](https://www.mastercam.com/news/blog/everything-you-need-to-know-about-cnc-machining-for-injection-mold-making/) is essential.

Mold Material: P20 vs. H13 Steel

The choice of steel depends on the required production volume. For prototypes or lower volume runs (under 100,000 parts), a pre-hardened tool steel like P20 is a cost-effective choice. For high-volume, million-part production runs, we use a much harder, more durable through-hardened steel like H13. H13 steel costs more and is harder to machine, but its longevity ensures part consistency over the entire project life.

Gates, Runners, and Ejection Systems

Getting plastic into the mold and the part back out is a science. The runner is a channel that carries molten plastic from the machine's nozzle to the part cavity. The gate is the small opening where the plastic enters the cavity. The gate's location and size are critical for controlling flow and minimizing cosmetic blemishes. Once the part is cooled, a system of ejector pins pushes the finished part out of the mold.

What Are the Main Methods for Mass-Producing Plastic Parts?

While injection molding is the king of plastic manufacturing, it's not the only option. The geometry of your part and the required volume will determine the most efficient process.

Injection molding is the standard for high-volume, complex 3D parts. For continuous 2D shapes like pipes or window frames, extrusion is used. And for hollow objects like bottles or tanks, the method of choice is blow molding.

Injection Molding: The Workhorse

This process is dominant for a reason: it's incredibly fast, repeatable, and can produce parts with amazing complexity.

| Step | Action |

|---|---|

| 1. Clamping | The two halves of the steel mold are clamped shut with hundreds of tons of force. |

| 2. Injection | Molten plastic is injected at high speed and pressure into the mold cavity. |

| 3. Cooling | The plastic is held in the mold under pressure while it cools and solidifies into the part shape. |

| 4. Ejection | The mold opens, and the ejector pins push the finished part out. |

Extrusion: For Continuous Profiles

Think of extrusion like squeezing toothpaste from a tube. Plastic pellets are melted and forced through a shaped die to create a continuous profile with a fixed cross-section. This process is used to make things like pipes, tubing, weather stripping, and window frames.

CNC Machining of Plastics

For very low quantities, prototypes, or parts with extremely tight tolerances that are impossible to mold, we can machine parts directly from a solid block or sheet of plastic. This is a "subtractive" process, just like with metals. It's slower and more expensive per-part for high volumes but offers great precision and avoids the high upfront cost of a mold.

How Do You Ensure Every Plastic Part Meets Specification?

Your reputation depends on shipping a perfect product every time. A single bad batch of parts can cause field failures and recalls. How do you guarantee consistency from the first part to the millionth?

A rigorous quality management system, like the ISO 9001 standard, is the key. It combines incoming material checks, First Article Inspections (FAI), in-process monitoring, and final inspection to ensure every part meets the required specifications.

First Article Inspection (FAI)

Before we begin mass production, we produce a small batch of "first article" parts. We then conduct a full dimensional layout, measuring every feature on the part drawing and comparing it to the actual part. This FAI report, a key part of our PPAP process, is sent to the client for approval. This guarantees that the mold is correct before we run thousands of parts.

In-Process Checks

Quality isn't just checked at the end; it's built into the process. Our machine operators and quality technicians perform regular checks throughout the production run. They pull parts from the line at set intervals (e.g., every hour or every 500 shots) to check critical dimensions and look for any cosmetic defects. This allows us to catch any small deviations before they become big problems.

Secondary Operations and Assembly

Our role often goes beyond just molding. Many parts require secondary operations, such as ultrasonic welding to join two pieces, pad printing to add a logo, or installing threaded inserts. As a one-stop hardware supplier, we can also assemble these plastic parts with our screws, fasteners, and other metal components to deliver a finished, ready-to-use sub-assembly.

About the Author

My name is Kevin. After years of sourcing industrial components in the US, I founded Prime Metals in 1993 with a simple goal: build things right. While our core is metal, our growth has been driven by providing complete hardware solutions. That's why we've invested heavily in our plastics division, running it with the same rigorous ISO 9001 quality standards and engineering-first approach that has defined our success for over 30 years.

Frequently Asked Questions (FAQs)

What's the difference between plastic injection molding and 3D printing?

Injection molding is a mass-production technique that is very fast and cheap per-part, but has a high upfront mold cost. 3D printing is an additive process that builds parts layer-by-layer directly from a digital file. It's much slower and more expensive per-part, but has no tooling cost, making it ideal for prototypes and very low-volume production.

How much does a plastic injection mold cost?

The cost varies dramatically based on the part's size, complexity, and the type of steel used. A simple, single-cavity mold from P20 steel might cost a few thousand dollars, while a large, complex, multi-cavity mold from hardened H13 steel for a high-volume automotive part could cost over $100,000.

What are common defects in plastic parts?

Common defects include "sink marks" (surface depressions), "warp" (distortion from the intended shape), "flash" (excess plastic leaking from the mold), "short shots" (incomplete parts), and "burn marks" from overheated material. A good DFM process and process control can prevent these.

From Engineering Challenge to Production Reality

The manufacturing of industrial plastic components is a precise, multi-stage process where success is determined long before the first part is ever made. It requires a deep understanding of design, materials science, and process engineering.

Ready to turn your design into a high-quality physical product? Partner with a team that has the experience to guide you through every step.

2 Responses

Thanks for your helpful post. Through the years, I have been able to understand that the actual symptoms of mesothelioma cancer are caused by a build up connected fluid between your lining of your lung and the upper body cavity. The illness may start inside chest spot and propagate to other areas of the body. Other symptoms of pleural mesothelioma cancer include losing weight, severe inhaling trouble, fever, difficulty eating, and puffiness of the neck and face areas. It should be noted that some people existing with the disease will not experience every serious signs or symptoms at all.

Hi there, thanks for leaving a comment.

Our website mainly focuses on industrial manufacturing topics such as plastic components, CNC machining and custom metal parts. Your message seems to relate to a medical topic, which is outside the scope of our content.

If you have any questions regarding industrial processes or material selection, feel free to share—we’re always glad to help.