Lost Wax Casting Process: How Does Investment Casting Ensure Such High Precision?

You have a complex metal part design, but the quotes for CNC machining are astronomical. Sand casting can't deliver the fine details or smooth finish you need. How do you manufacture this part affordably?

The lost wax casting process, or investment casting, ensures precision by creating a single-use ceramic mold around a disposable wax pattern. This process eliminates parting lines and mold shifts, allowing for intricate details and excellent surface finishes directly from the casting.

In my 30+ years in this business, I've seen countless projects get stuck at this exact crossroads. Back in my buying days, I had a project for a series of small, intricate valve bodies for Siemens. Machining them from solid stock was a non-starter on cost. We turned to investment casting. The initial tooling cost was a factor, but the per-piece price was a fraction of machining, and the quality was superb. This process is one of the oldest metal-forming techniques, yet it remains one of the best for complex, high-precision components. Let's walk through why.

What Are the Key Steps in the Lost Wax Process?

The process seems complex, almost like magic. A model made of wax becomes a high-strength steel part. How does this transformation actually happen on the factory floor?

The process is a precise, multi-stage journey. It starts with creating a wax replica of your part, coating it in ceramic to build a mold, melting the wax out, and then pouring molten metal into the hollow cavity.

The Journey from Wax to Metal

At our factory, the casting parts division follows this meticulous process for every production run, ensuring consistency and quality. It is a true blend of modern technology and careful craftsmanship. Each step builds upon the last, and a mistake anywhere in the chain can compromise the final part. This is why strict process control, as mandated by our ISO 9001 certification, is so critical.

The 7 Core Process Steps

Here is the step-by-step breakdown we use every day:

| Step # | Process Name | Description |

|---|---|---|

| 1 | Wax Pattern Injection | Molten wax is injected into a polished aluminum mold to create an exact replica. |

| 2 | Pattern Assembly | Multiple wax patterns are attached to a central wax spine, creating a "tree." |

| 3 | Shell Building | The tree is dipped repeatedly into a ceramic slurry and sand stucco to build a shell. |

| 4 | Dewaxing (Lost Wax) | The tree is placed in a high-temperature autoclave to melt and drain the wax out. |

| 5 | Casting | The now-hollow ceramic shell is pre-heated and filled with molten metal. |

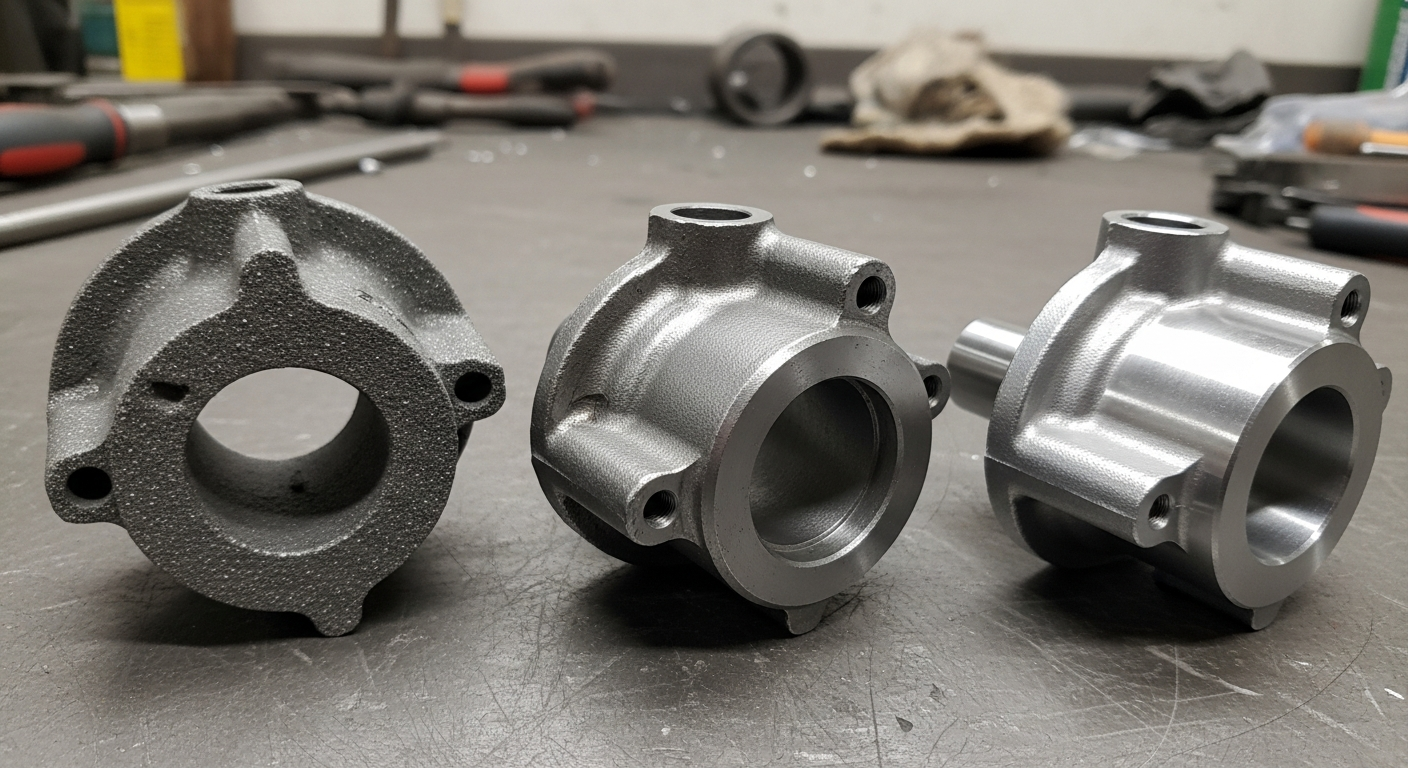

| 6 | Knockout & Finishing | Once cool, the ceramic shell is broken away. Parts are cut from the tree. |

| 7 | Heat Treatment & QC | Parts are heat-treated for strength and inspected for dimensional accuracy. |

Why Choose Investment Casting Over Other Methods?

You have options for making metal parts. Sand casting is cheap, and CNC machining is precise. Why would you select investment casting, which seems to fall in the middle?

Choose investment casting when your part's geometry is too complex for sand casting but the volume is too high to make CNC machining cost-effective. It offers the best balance of design freedom and repeatable precision.

Complexity and Design Freedom

Investment casting's greatest strength is its ability to produce "net-shape" or "near-net-shape" parts. This means the cast part is very close to the final required dimensions. You can design internal passages, undercuts, thin walls, and complex features that would be impossible or incredibly expensive to machine from a solid block. This often allows you to combine several simpler parts into a single, stronger casting, reducing assembly costs.

Surface Finish and Tolerances

The surface of the wax pattern is very smooth, and the ceramic slurry is made of extremely fine particles. This translates to a vastly superior surface finish compared to the grainy texture of sand casting. This often eliminates the need for secondary machining operations, saving both time and money. While not as tight as a high-end CNC part, the tolerances are excellent for most industrial applications.

Method Comparison at a Glance

| Feature | Sand Casting | Investment Casting | CNC Machining |

|---|---|---|---|

| Complexity | Low | High (undercuts, internal features) | Very High (but can be limited by tool access) |

| Surface Finish | Rough (12.5 - 25 µm Ra) | Excellent (1.6 - 3.2 µm Ra) | Excellent to Perfect (can be controlled) |

| Tooling Cost | Low | Medium - High | None (programming and setup time) |

| Per-Piece Cost | Very Low | Medium | High (especially for complex parts) |

| Best For | Large, simple parts (engine blocks, pipes) | Complex, medium-sized parts (valve bodies) | Prototypes, very high-precision parts, low volume |

Which Materials Are Best Suited for Precision Investment Casting?

Your application requires high strength, corrosion resistance, or performance at high temperatures. Can the lost wax process handle the advanced alloys you need?

Investment casting is incredibly versatile, compatible with a vast range of ferrous and non-ferrous metals. It excels with stainless steels, carbon steels, and superalloys that are often difficult to machine.

Stainless and Carbon Steels

This is the heartland of industrial investment casting. We cast everything from 304 and 316 stainless steel for food-grade and marine applications to various carbon and alloy steels for structural components. The process allows us to create strong, corrosion-resistant parts for pumps, valves, and machinery without the waste of machining from expensive stainless bar stock.

Superalloys and Exotic Metals

For aerospace and high-performance applications, investment casting is the preferred method for working with nickel-based and cobalt-based superalloys. These materials are chosen for their incredible strength at extreme temperatures but are notoriously difficult and expensive to machine. Casting them to near-net shape is far more efficient.

Non-Ferrous Alloys

While less common for our industrial focus, the process is also perfect for aluminum, bronze, and copper alloys, especially in the art and jewelry world. The principle is the same, just with lower melting temperatures. As the Investment Casting Institute notes, the process's versatility is one of its key advantages.

How Does Tooling Impact the Cost and Quality of My Cast Parts?

You received a quote for investment casting. The part price is great, but the one-time tooling cost seems high. What are you actually paying for, and is it worth it?

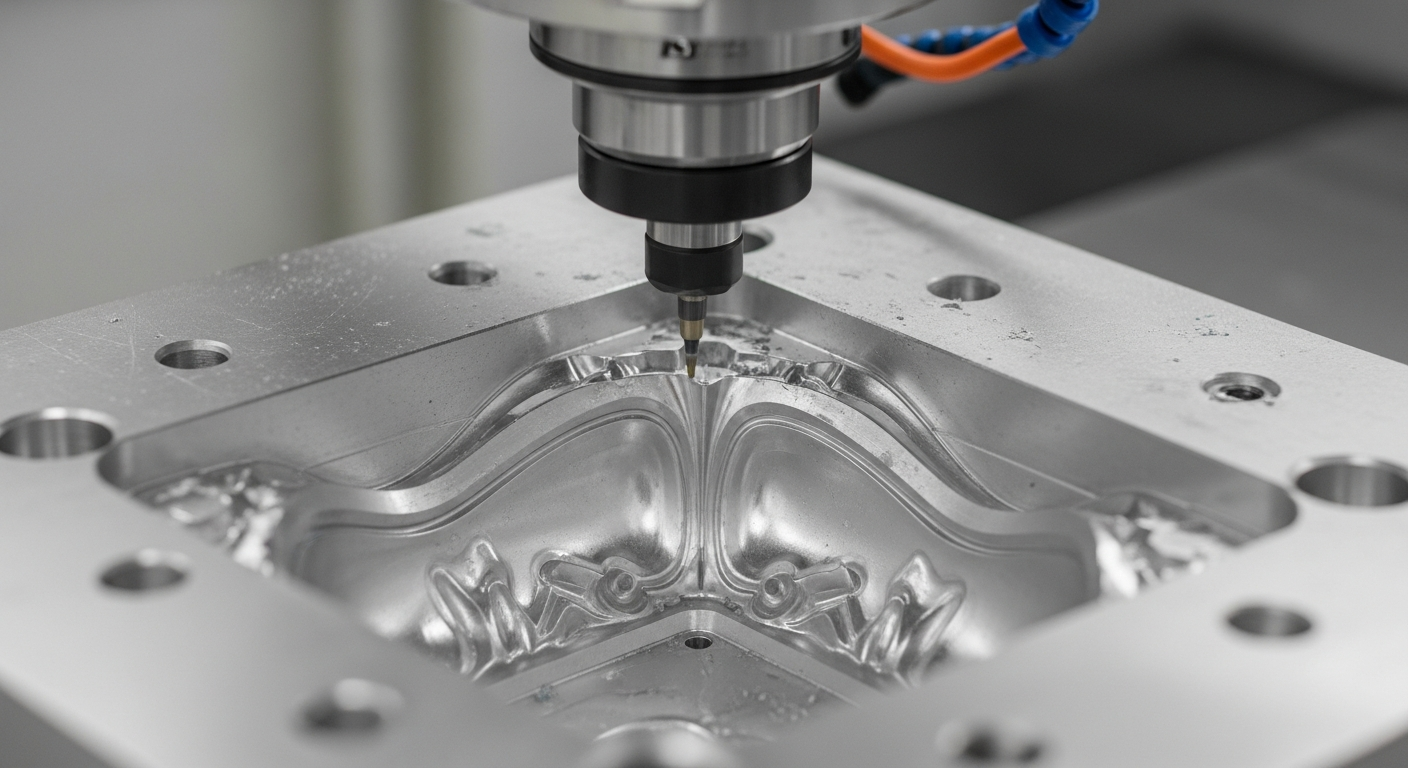

The "tool" is the high-precision aluminum mold used to create the wax patterns. Its cost is a one-time investment, and its quality directly determines the accuracy, consistency, and surface finish of every single part you produce.

What Makes a Good Tool?

A high-quality tool is a piece of precision engineering in itself. It's typically machined from a solid block of aluminum. We must account for the shrinkage of both the wax and the final metal, which are different for every alloy. The parting lines of the tool must meet perfectly to avoid creating a visible seam on the wax pattern. The surface inside the tool must be polished to a mirror finish, as any scratch will be replicated on every wax pattern and, ultimately, on every metal part.

The Cost vs. Longevity Equation

The upfront tooling cost can range from a few thousand to tens of thousands of dollars, depending on the part's complexity. However, this tool can produce tens of thousands, or even hundreds of thousands, of identical wax patterns. When you spread that initial investment across a large production run, the contribution to the final piece price becomes very small. This is why investment casting is ideal for medium-to-high volume production.

Design for Manufacturability (DFM)

Before we ever cut metal for a tool, our engineers perform a DFM analysis. We look for ways to optimize your design for the casting process—adjusting wall thicknesses, adding fillets, and planning the gating (where the metal enters the mold) to ensure a sound, defect-free part. This collaborative step is crucial for avoiding problems down the line.

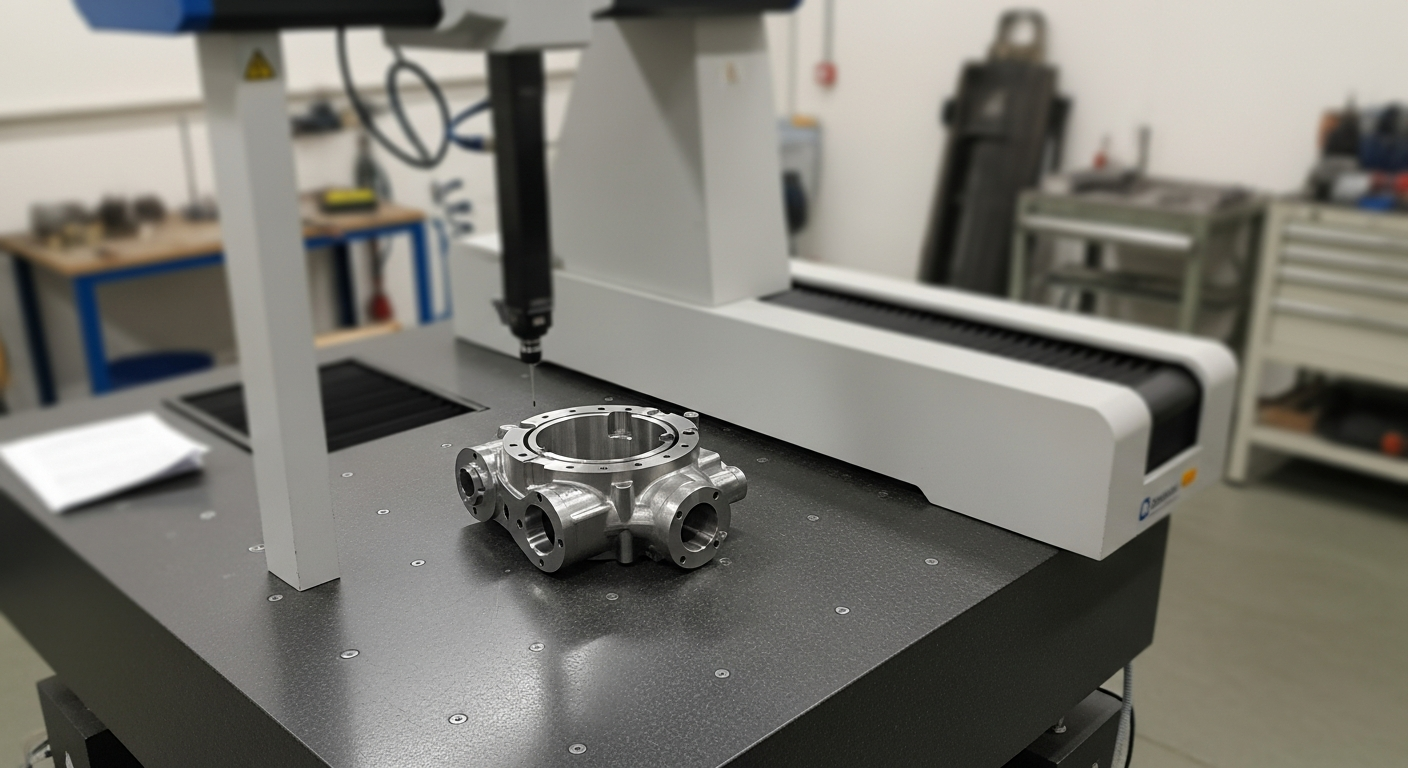

What Are the Critical Quality Control Checks for Investment Cast Components?

You've approved production. How can you be sure that the ten-thousandth part you receive is identical in quality and strength to the first one you approved?

Quality is not an accident; it's a system. For investment casting, it involves rigorous checks at every stage, from inspecting the initial wax patterns to final material analysis and dimensional verification of the metal parts.

In-Process Inspections

We don't wait until the end to check for quality. Our operators perform visual inspections on every wax pattern, looking for bubbles or flaws. We constantly monitor the temperature and viscosity of the ceramic slurry. The temperature of the molten metal is checked with a probe right before pouring. This in-process control, detailed in our ISO 9001:2015 procedures, prevents defects before they happen.

Final Part Verification

Once the parts are finished, they go to our dedicated QA lab.

- Dimensional Inspection: We use calipers, gauges, and a Coordinate Measuring Machine (CMM) to verify that all critical dimensions are within the specified tolerances.

- Material Analysis: We use a spectrometer to analyze the chemical composition of a sample from each batch, ensuring the correct alloy was used and meets international standards.

- Mechanical Testing: If required, we can perform tensile tests, hardness tests, and non-destructive testing like X-ray or magnetic particle inspection to check for internal integrity.

This complete documentation is part of the PPAP (Production Part Approval Process) package we provide to give you complete confidence in our parts before they ever ship.

About the Author

My name is Kevin. I founded Prime Metals in 1993 after years of working as a buyer in the United States. I built this company on the principle of being a true partner, not just another supplier on a list. We believe that understanding the "why" behind every manufacturing process is the key to delivering components that are not just made to spec, but built for performance and success.

Frequently Asked Questions (FAQs)

What is the typical tolerance for investment casting?

A general tolerance for investment casting is around +/- 0.1 mm for the first 25 mm, with an additional +/- 0.02 mm for each subsequent centimeter. However, this can vary greatly depending on the part size, geometry, and material.

Is investment casting more expensive than die casting?

The tooling for investment casting is generally less expensive than for high-pressure die casting. However, the process cycle is slower, making the per-piece price higher. Investment casting is used for steel and high-temp alloys, while die casting is limited to lower-temp alloys like aluminum and zinc.

What is the main advantage of lost wax casting?

The main advantage is its ability to produce complex, intricate shapes with a high-quality surface finish and good dimensional accuracy, reducing or eliminating the need for secondary machining.

The Smart Choice for Complex Metal Parts

The lost wax process is a powerful manufacturing tool. It bridges the gap between the cost-effectiveness of casting and the precision of machining. For the right part, it delivers unbeatable value.

Let our team of experts help you determine if investment casting is the right solution for your project.