How Do You Choose a Reliable MIG Welding Machine for Industrial Fabrication?

Your production line has ground to a halt. The reason? A cheap welding machine has failed under the pressure of a full-shift workload, and now you're facing costly downtime and project delays.

To choose a reliable industrial MIG welder, you must look past the price tag and focus on its duty cycle, amperage range, and build quality. An industrial machine is defined by its ability to deliver consistent power all day long without overheating.

At our factory, our welding and assembly services are fundamental to delivering complete products to our clients. We join stamped components, fabricate custom frames, and build complex assemblies every single day. Over the past 30 years, I've bought dozens of welding machines. I've learned the hard way that a reliable welder isn't an expense; it's an investment in uptime and quality. Let me share what I've learned, so you can make the right choice for your shop.

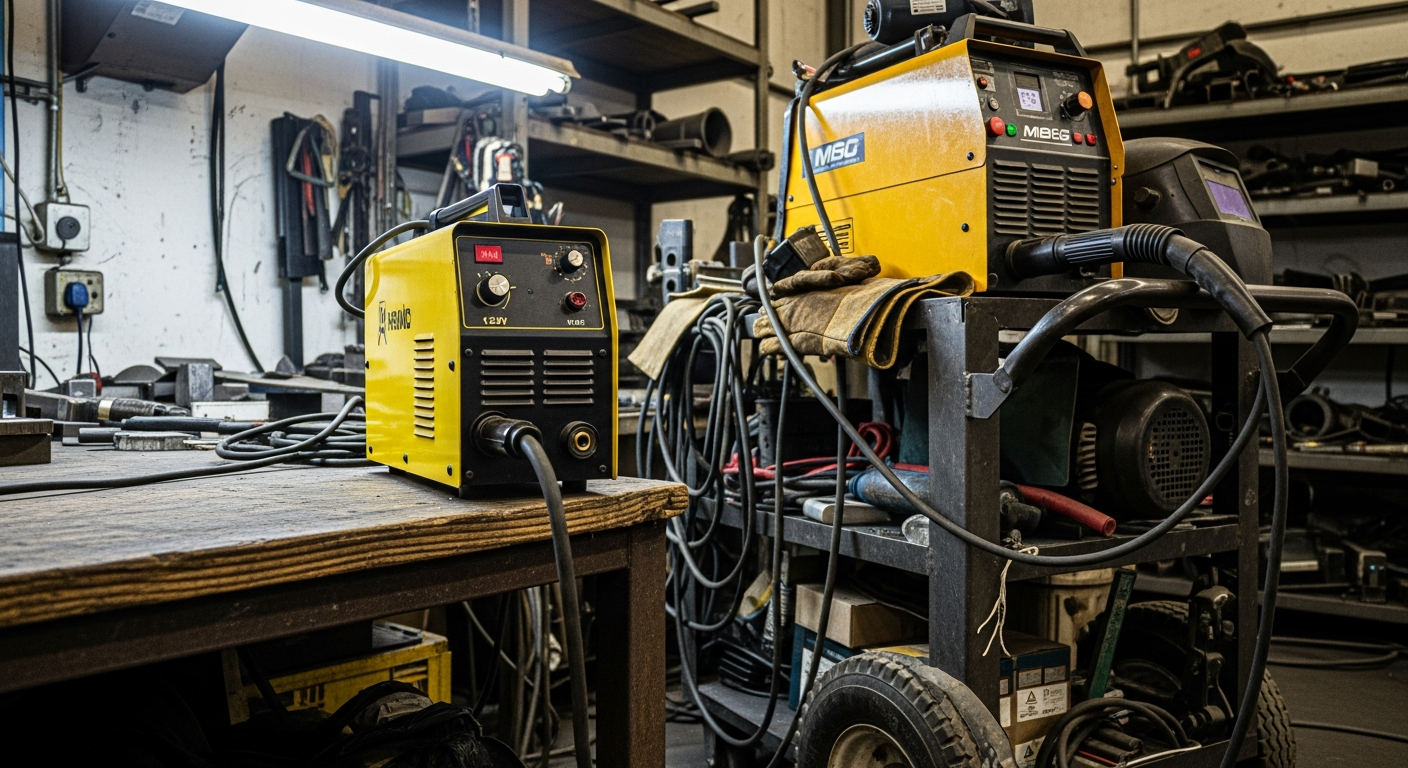

What's the Real Difference Between a Hobby Welder and an Industrial Machine?

You see two MIG welders online. One costs $800, the other $4,000. They both claim to weld steel, so why the huge price gap? It's a trap that many new buyers fall into.

The single most important difference is the duty cycle. This rating tells you how long a machine can weld continuously in a 10-minute period before it needs to cool down. Industrial machines are built for long, demanding weld times.

Duty Cycle: The Ultimate Test

Duty cycle is expressed as a percentage at a specific amperage. For example, a hobby machine might be rated at "20% at 90 amps." This means it can only weld for 2 minutes out of every 10 before it must cool down for 8 minutes. An industrial machine might be rated at "60% at 250 amps," allowing it to run for 6 straight minutes at high power. For production work, a high duty cyclee](https://www.weldclass.com.au/blog/43-welding-machines-what-is-duty-cycle-how-is-it-calculated) is non-negotiable.

Internal Build Quality

What's inside the box matters. Industrial machines use heavy-duty components designed for longevity.

| Component | Industrial Machine Standard | Hobby Machine Standard |

|---|---|---|

| Wire Drive | Cast aluminum or steel 4-roll drive | Plastic or 2-roll drive |

| Transformer | Copper-wound, large, heavy | Aluminum-wound, smaller, lighter |

| Power Cables | Thick, heavy-gauge copper | Thinner, less durable cables |

| Chassis | Heavy-gauge steel | Thin sheet metal and plastic |

Input Power Requirements

Most hobby machines run on standard 120V or 240V single-phase power. True industrial machines almost always require a 208/240V or 480V three-phase power supply, which is common in commercial and industrial buildings. This allows them to deliver more power, more efficiently and consistently.

How Do You Match Amperage to Your Material Thickness?

You've bought a powerful machine, but your welds on thick plate are weak and just sitting on the surface. Conversely, your welds on thin sheet metal are burning right through. This is a classic mismatch of power to material.

The key is to select a machine with an amperage range that covers your most common work. A good rule of thumb for steel is to use one amp of power for every 0.001 inch (or "thou") of material thickness.

The "One Amp Per Thousandth" Rule

This simple guideline is the perfect starting point for setting up a machine for mild steel.

- 1/16" Steel: 0.0625 inches → Requires ~60-70 amps.

- 1/8" Steel: 0.125 inches → Requires ~120-130 amps.

- 1/4" Steel: 0.250 inches → Requires ~250 amps. This is why a 140-amp machine is fine for sheet metal but completely inadequate for fabricating a 1/4" steel frame.

Amperage for Different Metals

Not all metals are the same. Aluminum, for example, is an excellent thermal conductor, which means heat dissipates from the weld zone very quickly. Because of this, it requires significantly more amperage and faster travel speeds than steel of the same thickness. Stainless steel requires slightly less amperage than mild steel.

A Practical Power Guide

| Common Task | Material Thickness | Required Amperage (Approx.) | Machine Class Needed |

|---|---|---|---|

| Sheet Metal Fabrication | 16-22 gauge (0.06"-0.03") | 40A - 90A | 140A - 180A |

| General Fabrication & Repair | 1/8" - 3/16" steel | 120A - 180A | 200A - 250A |

| Structural Steel & Heavy Plate | 1/4" and up | 250A+ | 250A - 500A+ |

What Optional Features Actually Improve Industrial Performance?

Spec sheets are filled with marketing terms like "synergic control," "pulse welding," and "inverter technology." It's hard to know which features are genuinely useful and which are just gimmicks.

For industrial use, the most valuable features are those that improve consistency and reduce operator error. A four-roll wire drive system, clear digital displays, and synergic controls are far more important than a dozen obscure weld modes.

The Wire Drive System: 2-Roll vs. 4-Roll

The wire feeder pushes the welding wire through the gun to the workpiece. A cheap 2-roll drive system can struggle to push wire smoothly, especially over long distances, leading to an erratic arc and poor welds. A 4-roll drive system grips the wire from two points, providing a powerful, consistent feed that is essential for professional work, especially with softer wires like aluminum.

Synergic vs. Manual Controls

On a traditional welder, you set the voltage and wire feed speed independently. Synergic control simplifies this. You select the material type and thickness, and the machine automatically sets the optimal parameters. This is fantastic for consistency, especially in shops where multiple operators with different skill levels use the same machine.

Inverter vs. Transformer Technology

Older machines use heavy transformers to convert power, while modern machines use lightweight inverter technology. According to the American Welding Society (AWS), inverters offer significant benefits. They are much lighter, more energy-efficient, and offer a smoother, more stable welding arc. Many inverters also enable advanced features like pulse welding, which is excellent for thin materials and aluminum.

How Is a MIG Welder Set Up for a Consistent, Quality Weld?

A top-of-the-line machine will produce terrible welds if it's not set up correctly. Porosity, spatter, and weak joints are almost always caused by an issue in the setup, not the machine itself.

A perfect weld requires the right balance of four things: the correct shielding gas, a clean workpiece, a solid ground connection, and the proper ratio of wire feed speed to voltage.

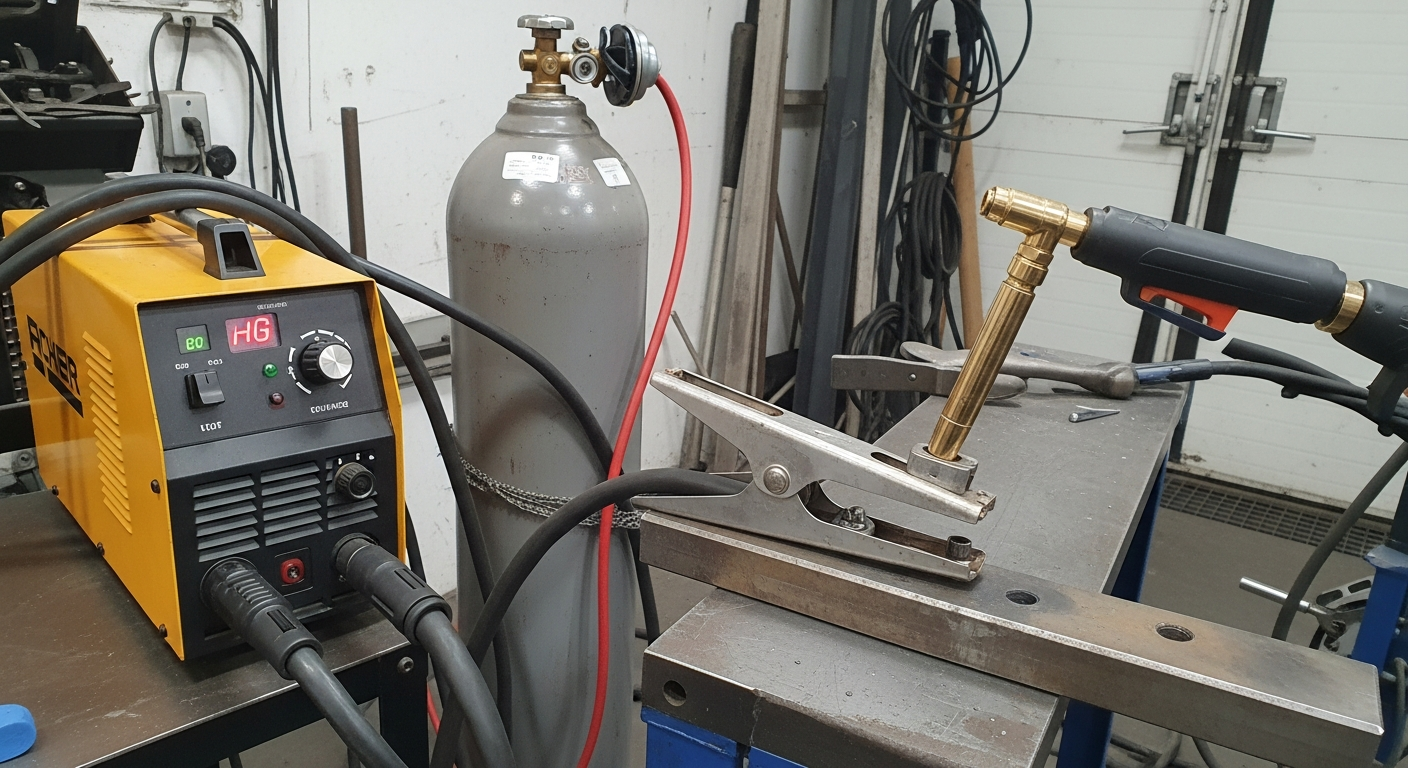

Choosing the Right Shielding Gas

The shielding gas protects the molten weld pool from contamination by oxygen and nitrogen in the air. Using the wrong gas is a recipe for disaster.

| Metal | Recommended Shielding Gas |

|---|---|

| Mild Steel | 75% Argon / 25% CO2 (C25) is the industry standard. |

| Stainless Steel | A "tri-mix" of Helium/Argon/CO2 is often used. |

| Aluminum | 100% Argon. |

Workpiece Preparation and Grounding

You cannot create a good weld on a dirty surface. All rust, paint, oil, and mill scale must be removed from the weld area with a grinder or wire wheel. Just as important is the ground clamp. It must be attached to a clean, bare metal spot on the workpiece to ensure a stable electrical circuit. A weak ground is one of the most common causes of weld problems.

Dialing in the Settings

The relationship between wire feed speed (which controls amperage) and voltage (which controls arc length) is critical. If your settings are right, the welder should produce a steady, smooth "crackling" or "sizzling" sound. If it's making a loud hissing noise with lots of spatter, your voltage is likely too high. If it's stubbing into the workpiece with a clunky, rhythmic sound, your wire speed is too high.

How Does a Certified Factory Ensure Reliable Welded Assemblies?

As a buyer, how do you know your supplier's welding process is reliable? A fancy machine means nothing without a system to back it up.

A reliable welding operation is built on the foundation of a quality management system like ISO 9001. This system ensures that all welders are qualified, all machines are calibrated, and all jobs follow a documented, repeatable procedure.

Welding Procedure Specification (WPS)

For critical components, especially those made from our stamping parts or CNC parts, we don't just "start welding." We develop a WPS. This is a formal, written document that provides direction for making a specific production weld. It details the gas type, voltage, travel speed, and technique to be used. This ensures that the first weld and the ten-thousandth weld are identical.

Welder Qualification

A great machine is useless in untrained hands. Our welders are formally qualified to our WPS documents. This means they have proven through testing that they have the skill to produce a sound weld according to the specified procedure. This is how we guarantee the quality and strength of every joint.

Maintenance and Calibration

In our factory, every welding machine is on a strict preventative maintenance schedule. We regularly inspect the liners, drive rolls, and contact tips. Furthermore, the machine's output (amps and volts) is periodically calibrated to ensure that what the screen says is what the machine is actually delivering. Consistency is everything in production.

About the Author

My name is Kevin. I started Prime Metals in 1993 after years of sourcing industrial hardware in the United States. I built this company on an engineering-first philosophy. Our expertise isn't just in making a part; it's in understanding the processes, like welding, that turn those parts into functional, reliable products for our global customers. Our ISO 9001 certification isn't just a plaque on the wall—it's how we run our shop every day.

Frequently Asked Questions (FAQs)

What does MIG stand for?

MIG stands for Metal Inert Gas welding. It's a process that uses a continuously fed solid wire electrode and a shielding gas to join metals. It is sometimes also referred to as Gas Metal Arc Welding (GMAW).

Can you MIG weld without gas?

Yes, this process is called flux-cored arc welding (FCAW). It uses a special wire with a flux compound in the center that creates its own shielding gas as it burns. While useful for outdoor work in windy conditions, it typically produces more spatter and a less clean weld than standard MIG welding.

How often should you change the contact tip?

The contact tip is a consumable part that transfers the electrical current to the wire. It should be inspected daily and replaced when the hole becomes oval-shaped or clogged with spatter. A worn tip will cause an unstable arc and poor weld quality.

From Machine Selection to Production Partnership

Choosing the right welding machine is the first step. But building a truly reliable product requires a partner who understands how to build a reliable process. It's about combining the right equipment with proven quality systems and skilled operators.

If you are looking for a manufacturing partner who can deliver high-quality welded assemblies, we're ready to help.