Glass Cloth Explained: A Complete Guide for Industrial, Electrical, and Composite Applications?

Picking the wrong reinforcement for your composite part can be a disaster. It leads to weak products, unexpected failures in the field, and costly rework. Let's make sure that doesn't happen.

Glass cloth is a woven fabric made from extremely fine glass filaments. It is the backbone of many composite materials, providing essential strength, stiffness, heat resistance, and dimensional stability for everything from printed circuit boards (PCBs) to industrial structural components.

Over my 30 years in manufacturing, I've seen many projects delayed because of a simple material misunderstanding. Glass cloth isn't just one material; it's a whole family of products. A client might specify "glass cloth" without realizing that the fiber type, weave style, and finish are critical details that determine if their final part will succeed or fail. Let's break down what you, as a buyer or engineer, really need to know to make the right choice.

What Are the Different Types of Glass Fibers Used in Cloth?

Staring at specs for E-glass vs. S-glass and not sure what it means for your budget? Choosing by name alone can lead to over-engineering and high costs or, worse, under-performance and failure.

The most common types are E-glass (Electrical-grade), the industry standard for its good performance and low cost, and S-glass (Strength-grade), which offers superior mechanical strength for high-performance applications. Other specialty types like C-glass (Chemical-resistant) also exist for specific environments.

E-Glass (Electrical Grade)

E-glass is the workhorse of the composite industry. It was originally developed for electrical applications because of its low alkali content, which makes it a great electrical insulator. Today, it represents the vast majority of all glass fiber produced. It provides an excellent balance of strength, stiffness, and cost. When you see a standard printed circuit board (PCB) or a general-purpose fiberglass part, it’s almost certainly made with E-glass. For most industrial and electrical applications, E-glass is the starting point and often the final choice.

S-Glass (Strength Grade)

When you need a significant step up in performance, you look at S-glass. It has a much higher tensile strength and modulus of elasticity than E-glass—we're talking about 30-40% stronger. This makes it the material of choice for demanding applications where failure is not an option, such as in aerospace components, ballistic armor, and high-performance sporting goods. Of course, this increase in performance comes with a higher price tag. We only specify S-glass when the application's mechanical load requirements truly demand it.

Other Specialty Glasses

While E-glass and S-glass cover most needs, you should be aware of other types. C-glass, for example, is formulated for superior resistance to chemical corrosion, making it ideal for storage tanks and piping in chemical plants. There is also A-glass (Alkali-glass), an older formulation that is less common now but can be found in applications where strength and durability are not primary concerns. The key is to match the glass type to the part’s operating environment. For more information on composites, the American Composites Manufacturers Association (ACMA) is an excellent resource.

| Property | E-Glass | S-Glass | Key Advantage |

|---|---|---|---|

| Main Use | General Purpose, PCBs | High-Performance, Aerospace | Varies |

| Tensile Strength | Good | Excellent (higher) | S-Glass is stronger |

| Stiffness (Modulus) | Good | Excellent (higher) | S-Glass is stiffer |

| Cost | Low | High | E-Glass is more economical |

| Electrical Insulation | Excellent | Good | E-Glass is standard |

How Do Weave Styles Affect Fabric Properties?

Struggling to form a fabric over a complex shape without wrinkles? The weave pattern is more than just a cosmetic detail; it dictates how the fabric will behave during manufacturing.

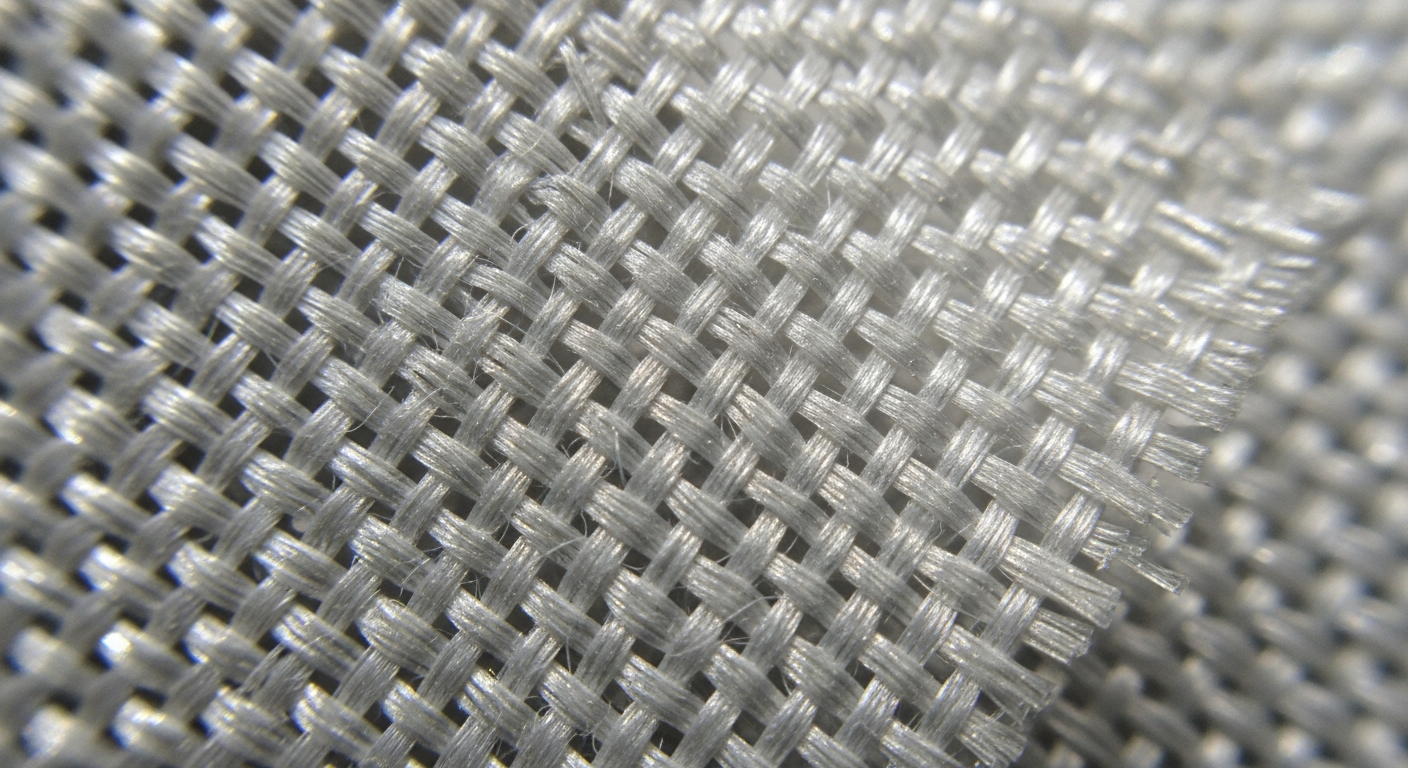

The weave style determines the fabric's stability, its ability to drape over curved surfaces, and the final surface finish. A plain weave is very stable but stiff, while a satin weave is highly flexible but can fray easily. A twill weave offers a popular balance between the two.

Plain Weave

This is the simplest and most common weave style, with each yarn passing over one yarn and then under the next. This creates a tight, stable fabric that resists stretching in the fiber directions. It’s like a simple checkerboard pattern. The downside is that all the tight crimps (bends) in the fibers make it very stiff. It doesn't drape well over complex, curved surfaces and can be difficult to work with. It's best suited for flat panels or simple shapes.

Twill Weave

You'd recognize a twill weave from your denim jeans. It has a characteristic diagonal rib pattern. In this style, a yarn floats over two or more yarns before passing under one. This reduces the number of crimps, making the fabric more pliable and conformable than a plain weave. It offers a great compromise between the stability of a plain weave and the flexibility of a satin weave, which is why it's a very popular choice for parts with compound curves.

Satin Weave

Satin weaves have even fewer interruptions, with yarns floating over several other yarns (e.g., 4, 5, or 8) before passing under one. This creates an extremely smooth, low-profile fabric that is highly drapable and perfect for forming over very complex shapes with a "Class A" surface finish. However, this loose structure makes the fabric less stable. It can be prone to distortion and fraying at the edges, requiring more careful handling during the layup process.

| Weave Style | Drapability (Flexibility) | Stability | Surface Finish | Best For |

|---|---|---|---|---|

| Plain | Low | High | Textured | Flat panels, simple shapes |

| Twill | Medium | Medium | Moderate | Compound curves |

| Satin | High | Low | Smooth | Complex shapes, cosmetic surfaces |

What Do Fabric Weight and Sizing Mean for My Application?

Is a heavier fabric always better? Choosing a fabric based on weight alone without understanding its finish can lead to a part that is overweight, brittle, or delaminates under stress.

Fabric weight, given in oz/yd² or g/m², determines the thickness and strength per layer. Sizing is a critical chemical coating applied to the fibers that enables the resin to bond securely to the glass. Without the correct sizing, your composite part will fail.

Fabric Weight (Areal Weight)

This number simply tells you how much the fabric weighs over a given area. A lightweight fabric (e.g., 2 oz/yd²) is thin and flexible, perfect for surface layers to provide a smooth finish or for making very thin laminates. A heavyweight fabric (e.g., 18 oz/yd²) will build thickness and strength much faster, but it also soaks up more resin and is less flexible. Sometimes, building a desired thickness with multiple layers of a lighter fabric can result in a stronger part than using a single layer of a very heavy fabric, as it distributes stress more effectively.

The Importance of Sizing (Finish)

This is a detail that buyers often overlook, but it's fundamentally important. Glass fibers themselves are very slick and do not bond chemically with resins. Sizing is a microscopic chemical finish applied to the fibers during their production. This coating acts as a coupling agent, creating a strong chemical bridge between the glass surface and the resin matrix (like epoxy, polyester, or vinyl ester). I once worked with a client whose parts were failing our peel tests. The issue wasn't the glass or the resin; it was that the glass cloth had a sizing meant for polyester resin, but they were using an epoxy system. The bond was purely mechanical and extremely weak.

Choosing the Right Combination

The perfect glass cloth for your project is a combination of the right fiber, weave, weight, and, critically, a sizing that is chemically compatible with your chosen resin system. When you send us an RFQ for a composite part on our contact page, we always ask about the part's intended use and operating environment. This allows our engineers to recommend the optimal combination of materials to meet your performance and cost targets.

How is Glass Cloth Used in PCBs and Electrical Insulation?

Wondering what makes the inside of your electronics rigid and reliable? Using the wrong internal substrate in a PCB can cause signal loss, overheating, and complete circuit failure.

Glass cloth is the primary reinforcement material in FR-4 laminates, the universal standard for Printed Circuit Boards (PCBs). It provides the mechanical structure and dimensional stability, while its excellent dielectric properties are crucial for ensuring signal integrity in circuits.

The Structure of FR-4

FR-4 is not a single material but a composite. It's made by impregnating several layers of E-glass cloth with a flame-retardant (FR) epoxy resin. This stack is then pressed under high heat and pressure to create a rigid, flat laminate. A thin layer of copper foil is bonded to one or both sides. This becomes the base material that is later etched to create the conductive traces of the circuit. The glass cloth provides the backbone, preventing the board from warping or breaking.

Dielectric Properties for Signal Integrity

In electronics, the insulating material can't just be an insulator; its electrical properties actively affect the circuit's performance. The glass cloth and resin system together determine the laminate's dielectric constant (Dk) and dissipation factor (Df). For high-speed digital circuits or high-frequency radio applications, a low and stable Dk/Df is essential to prevent signal loss and maintain clear communication. Different weave styles and lower-loss glass types are used for the most demanding RF applications.

Thermal Management and Reliability

Electronic components generate heat, and the PCB must be able to handle it. The glass cloth reinforcement has a very low coefficient of thermal expansion (CTE). This ensures the board remains dimensionally stable during the high temperatures of the soldering process and throughout its operational life. This stability is critical for preventing stress on solder joints, which is a common point of failure in poorly made electronics. Our rigorous quality control ensures all laminates we use meet these strict thermal requirements.

What Are the Key Quality Checks for Industrial Glass Cloth?

Have you ever received a roll of material with flaws that force you to scrap parts? Unchecked raw materials can bring your production to a halt and ruin your profit margins.

For quality assurance, your supplier must verify the fabric's weight and thickness, perform a thorough visual inspection for defects like broken fibers or stains, and provide a Certificate of Analysis (COA) that confirms the material specifications and correct sizing.

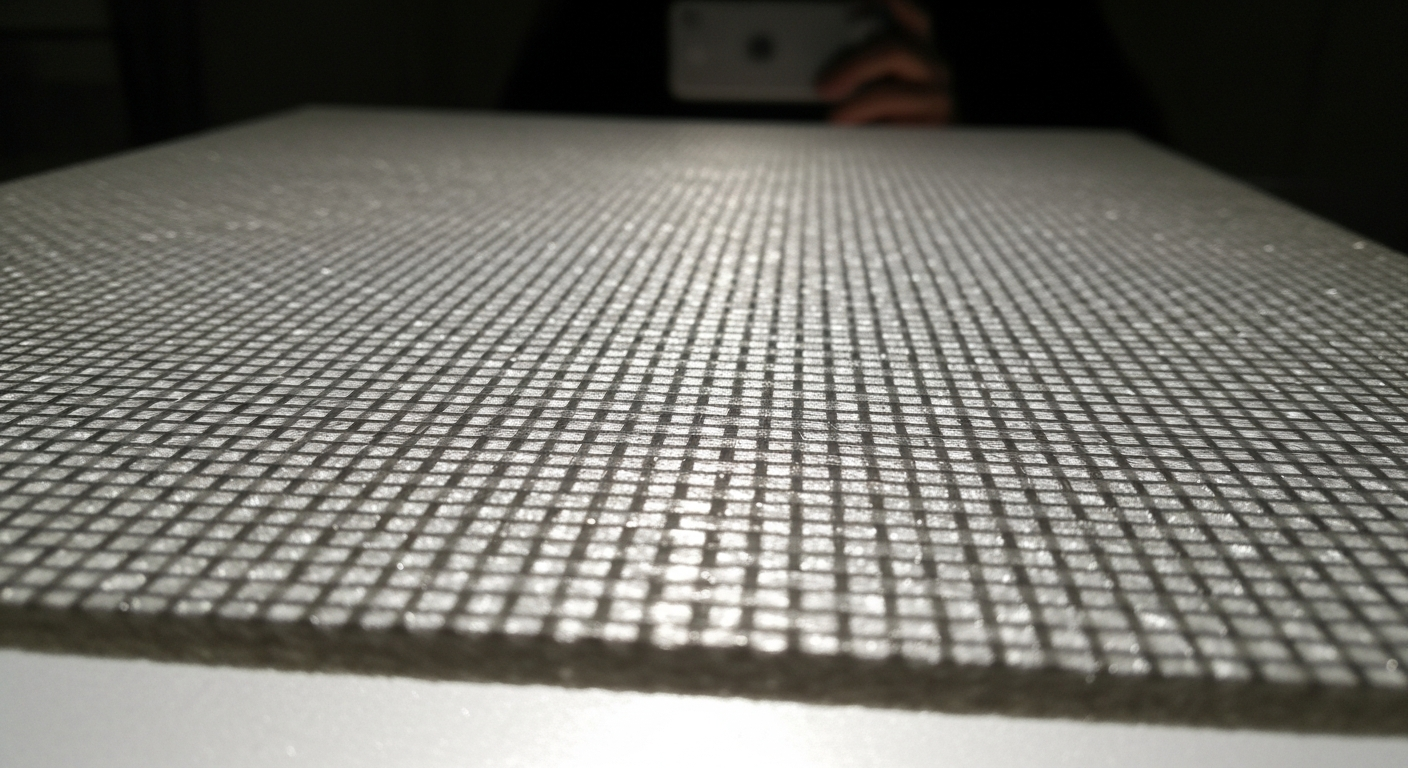

Visual Inspection and Defect Identification

The first line of defense is a simple but effective visual check. We unroll a sample of every incoming batch of glass cloth over a large light table. The backlighting makes it easy to spot any inconsistencies in the weave, broken filaments, large slubs (thicker sections of yarn), or contamination like oil spots or dirt. Any of these defects could create a weak point or a cosmetic flaw in the final composite part, so we identify and quarantine any non-conforming material immediately.

Verification of Specifications

Trust, but verify. Every shipment of glass cloth should come with a Certificate of Analysis (COA) from the manufacturer. Our quality team verifies this document against our purchase order specifications. We then take physical measurements from the roll to confirm properties like areal weight (g/m²) and fabric thickness. This ensures that what we ordered is what we received. This documented verification is a core requirement of our ISO 9001:2015 certified quality management system.

Traceability and Process Control

Knowing your material is good is one thing; proving it is another. Every roll of fabric that enters our factory is assigned a unique lot number. This number is logged in our system and follows the material all the way through the manufacturing process to the finished part. If any issue were to arise, we can instantly trace the final component back to the exact batch of raw material it came from. This level of traceability is essential for accountability and is something we provide for all our manufacturing services.

About the Author

I'm the general manager at Prime. With over three decades in the manufacturing sector, I've helped countless global companies navigate the complexities of sourcing industrial components. Our factory isn't just a collection of machines; it's a team of dedicated engineers and technicians committed to quality, precision, and partnership. My goal is to demystify manufacturing and be a trusted resource for your business.

Frequently Asked Questions (FAQs)

1. What is the difference between fiberglass mat and cloth? Fiberglass mat (like Chopped Strand Mat) consists of short, randomly oriented fibers bonded together. It's inexpensive and builds thickness quickly but isn't as strong as cloth. Glass cloth is a woven fabric with continuous fibers, providing much higher directional strength and a better surface finish.

2. Is glass cloth waterproof? The glass fibers themselves are impervious to water. However, a composite part's waterproofness depends entirely on the resin matrix. A properly fabricated part with a void-free resin like epoxy or vinyl ester will be completely waterproof.

3. How do you cut glass cloth? Glass cloth should be cut with very sharp, dedicated tools. Industrial-grade shears or a rotary cutter (like a pizza cutter) on a cutting mat work best. Be aware that glass will dull steel blades very quickly.

4. What is FR-4 material? FR-4 is the most common grade for printed circuit boards. It's a rigid composite laminate made from layers of woven E-glass cloth impregnated with a flame-retardant epoxy resin.

5. Can you use glass cloth with polyester resin? Yes, absolutely. Polyester resin is one of the most common resin systems used with glass cloth. However, you must ensure that the sizing (finish) on the glass cloth is specifically designed to be compatible with polyester resin to achieve a strong bond.

Conclusion

Selecting the right glass cloth is a critical decision. Success hinges on understanding how fiber type, weave style, weight, and chemical finish work together to meet the demands of your specific application.

<br>

Ready to build your next composite component with a partner who understands the details?