Industrial Metal Grates: How Do You Select the Right Grating for Heavy-Duty Applications?

You've specified a metal grate for a walkway, but after six months in service, it's starting to bend and corrode. A failing grate isn't just a replacement cost; it's a serious safety hazard.

To select the right industrial metal grate, you must first define the required load capacity, then choose a construction type (welded, press-locked), a material (steel, aluminum), and a finish (galvanized, painted) that matches the project's specific environmental and safety demands.

What Are the Main Types of Metal Grating Construction?

From a distance, all grating looks the same. But up close, the way it's held together is the single biggest factor in its strength, appearance, and cost.

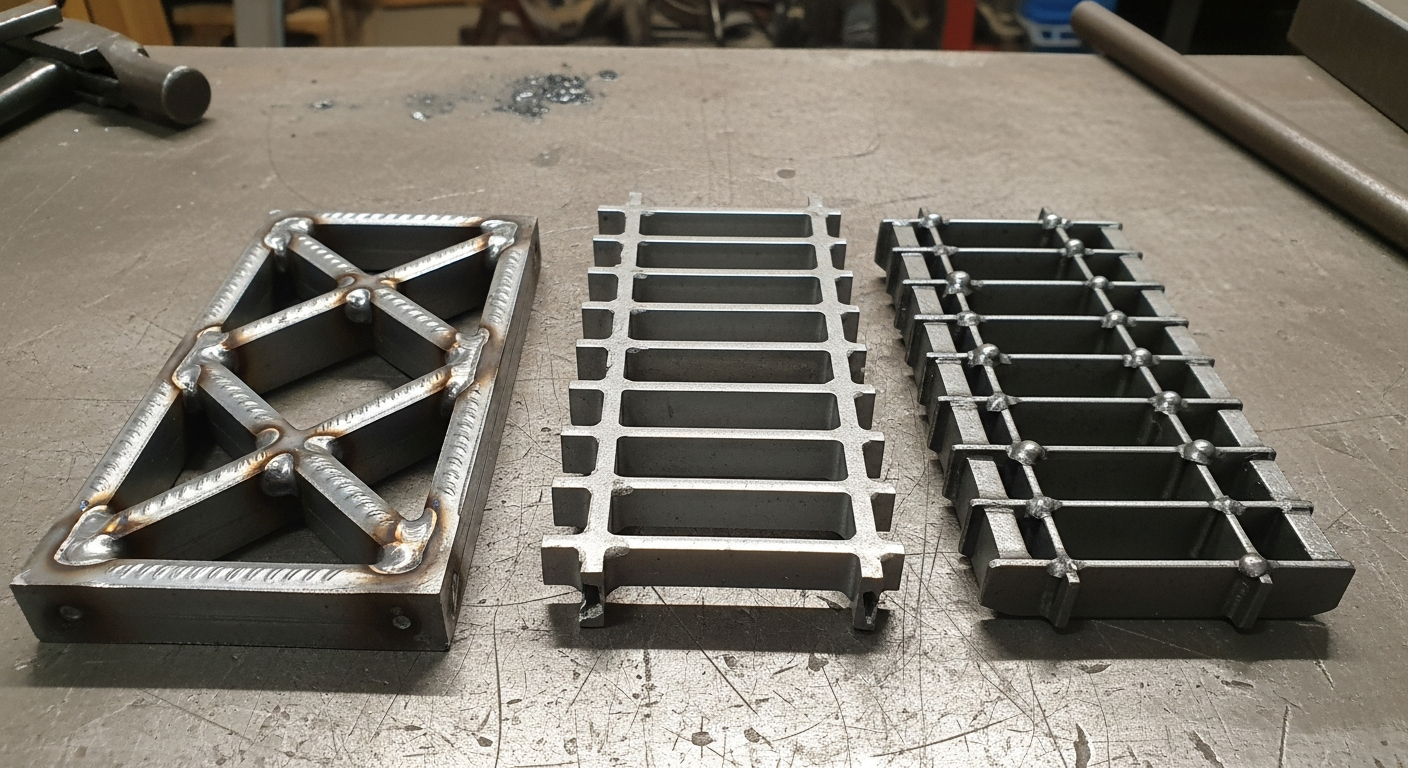

The three primary construction methods are welded, press-locked, and riveted. Welded bar grating is the most common and cost-effective for industrial use due to its strength and durability.

Welded Bar Grating: The Industry Standard

This is the workhorse of industrial grating. It's made by placing round cross rods into punched holes in the main bearing bars. The two are then permanently fused together using a high-pressure forge welding process. This creates a deep, strong bond at every intersection, making it incredibly robust and resistant to twisting. In our welding and assembly services department, we often fabricate custom frames and supports specifically for this type of grating.

Press-Locked Grating: The Architectural Choice

Instead of welding, press-locked grating is assembled like a puzzle. Both the bearing bars and the cross bars are notched. They are then pressed together under immense hydraulic pressure, locking them into a tight, rigid grid. This method produces a very clean, crisp appearance with smooth sightlines, making it a favorite for architectural applications, sunscreens, and shelving where aesthetics are important.

Riveted Grating: The High-Impact Solution

Though less common now due to its higher cost, riveted grating is still the champion in environments with extreme rolling loads or constant vibration. It’s made with bearing bars and a unique crimped bar that are joined by rivets at their intersection points. This construction provides excellent resistance to buckling and can handle the repetitive impact of heavy traffic better than other types.

How Do You Determine the Correct Load Capacity?

This is the most critical question. An under-specified grate is a catastrophic failure waiting to happen. How do you translate "a forklift will drive over it" into a technical specification?

Load capacity is determined by the bearing bar's height and thickness, the spacing between the bars, and, most importantly, the unsupported span. You must consult manufacturer load tables to make a safe selection.

Bearing Bar Size and Spacing

The bearing bars are the main load-carrying members that run parallel to the direction of the span. A taller and thicker bar is a stronger bar—it’s that simple. Increasing the bar height from 1” to 1-1/4” can dramatically increase its load capacity. Similarly, placing the bearing bars closer together (e.g., 1-3/16” on center vs. 1-1/8”) distributes the load across more bars, increasing strength. This, of course, also increases the weight and cost of the panel.

The Critical Role of Span

This is the single most common point of failure. The "span" is the distance between the supports holding the grating up. A grate that can support 1,000 lbs on a 2-foot span might only support 200 lbs on a 4-foot span. Doubling the span reduces the capacity by much more than half. You must know the exact distance between your supports before you can even begin to select the right grating profile.

Reading Load Tables

Every reputable grating manufacturer provides load tables that comply with standards from organizations like the National Association of Architectural Metal Manufacturers (NAAMM). These tables show two types of loads: "U" for uniformly distributed load (like snow or stored materials) and "C" for concentrated load (like a single wheel or post). You must select a grating that exceeds the maximum anticipated load for your known span.

Which Material and Finish Is Best for Your Environment?

You specified standard steel grating for a chemical processing plant, and now it's a rusty mess. The environment is just as punishing as the load.

Bare carbon steel is the most affordable but requires a protective finish. Hot-dip galvanizing is the standard for corrosion resistance in most industrial settings. Stainless steel or aluminum are used for more severe environments.

Carbon Steel: The Strong and Affordable Core

Most industrial grating starts as low-carbon steel (like ASTM A36). It offers excellent strength and is easily weldable, making it perfect for custom fabrication. However, left unprotected, it will rust quickly. It is almost always supplied with a finish. A simple coat of shop paint offers minimal, short-term protection, primarily for indoor, dry environments.

Hot-Dip Galvanizing: The Gold Standard Finish

This is the most durable and common protective finish for carbon steel grating. The entire fabricated panel is submerged in a bath of molten zinc. This process creates a thick, metallurgically bonded layer of zinc that provides multi-layered corrosion protection. You can learn more about the process on this informative Wikipedia article. It's the go-to choice for almost any outdoor or moisture-prone application.

Stainless Steel and Aluminum

When even galvanizing isn't enough, you step up to premium materials.

- Stainless Steel (304 or 316): Used in food processing, pharmaceutical, and chemical plants where chemical corrosion resistance and hygiene are paramount.

- Aluminum: Offers excellent corrosion resistance, especially in marine environments, and is significantly lighter than steel. Its lower strength means it requires deeper bearing bars for the same load, but it's ideal when weight is a primary concern.

What Surface Options Are Available for Safety and Accessibility?

A standard grating walkway is fine on a dry day. But what about in an oily machine shop or on an icy outdoor platform? Surface texture becomes a critical safety feature.

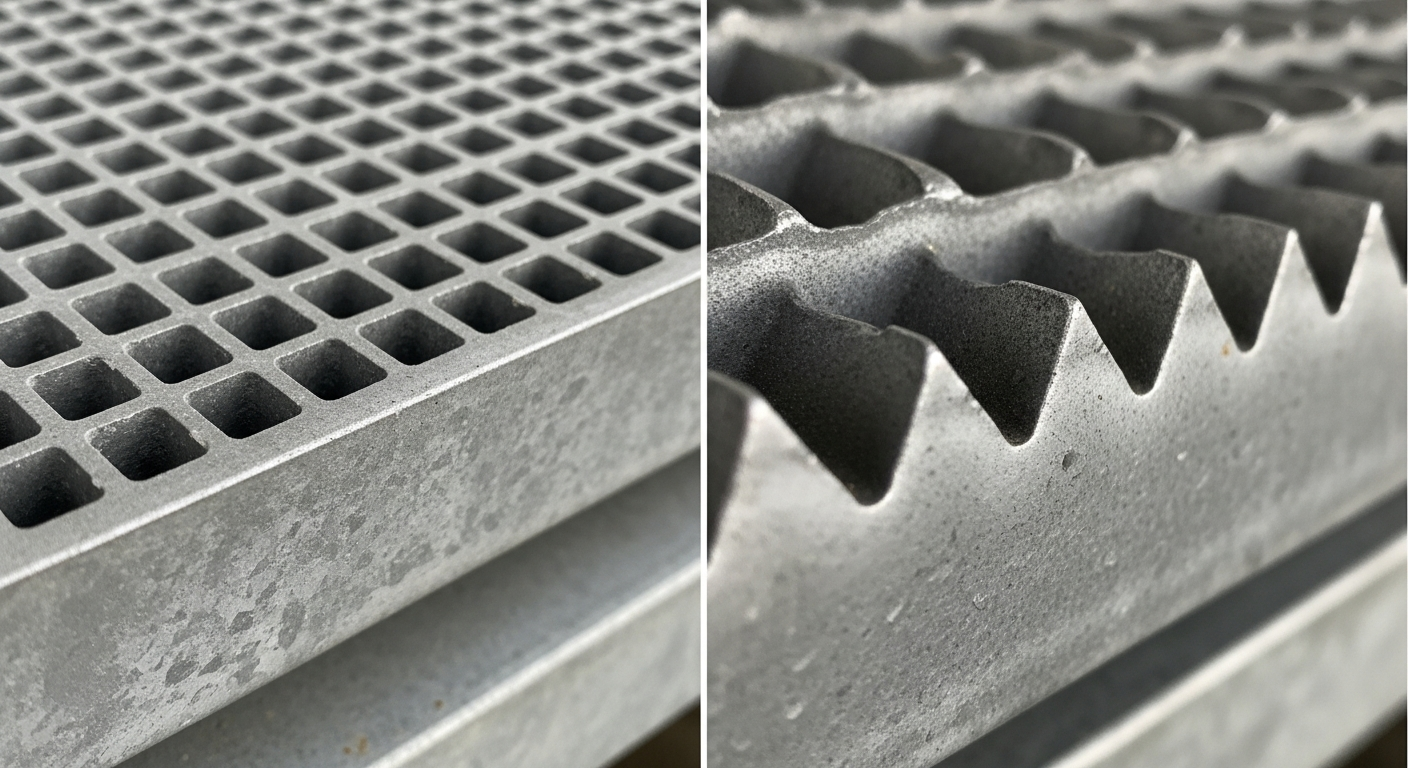

A plain surface is standard, but a serrated surface, with notches cut into the bearing bars, should be specified for any area where slips are a concern. Spacing can also be adjusted for ADA compliance.

Plain vs. Serrated Surfaces

The choice is simple: prioritize safety. A plain surface is smooth and sufficient for many standard applications. A serrated surface has small, sharp notches cut into the top edge of the bearing bars. This creates an aggressive, slip-resistant surface that provides superior grip for boots, even when the grating is wet, oily, or icy. The small additional cost for serration is negligible compared to the cost of a slip-and-fall accident.

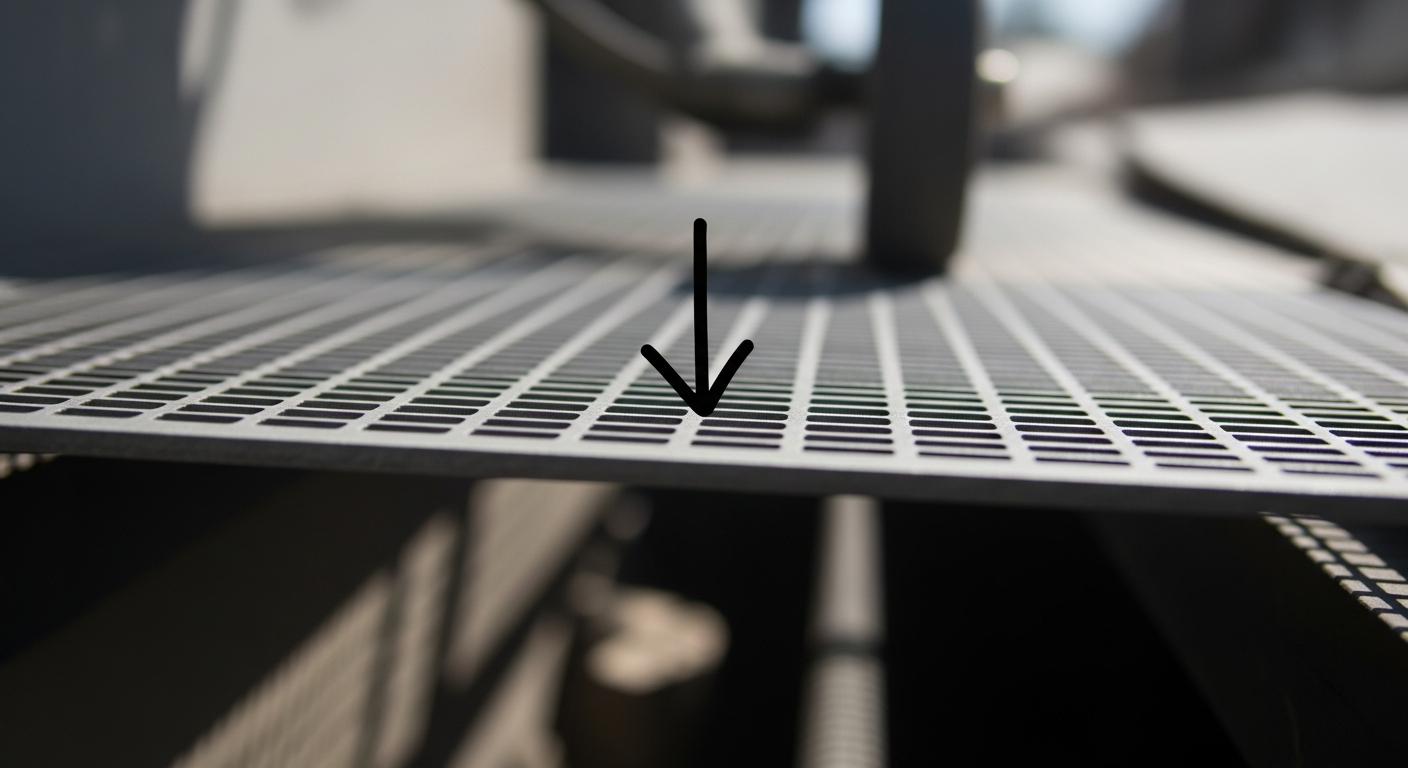

ADA Compliance and Close-Mesh Grating

For public walkways and areas accessible to the general public, grating must often be compliant with the Americans with Disabilities Act (ADA). This typically requires that the openings in the grating be no more than 1/2" wide in one direction to prevent mobility device wheels, canes, or high heels from getting stuck. This is achieved by using "close-mesh" grating with tighter bar spacing.

Custom Fabrications: Banding, Toe Plates, and Cutouts

Grating is rarely just a simple rectangle. It needs to fit around pipes, columns, and equipment. We provide custom-fabricated panels with cutouts made to your drawings. Open ends are typically banded (welded with a flat bar) for a finished look and to transfer load. For elevated walkways, toe plates (or kick plates) are welded around the edges to prevent tools or small items from being kicked off and falling on people below.

How Do You Verify the Quality and Integrity of Your Grating?

The grating arrives on site. It looks right, but how do you really know it meets the specifications you paid for? Is the steel the right grade? Are the welds strong?

Quality is verified through a certified manufacturing process. Partner with an ISO 9001 certified supplier who provides material traceability and can prove weld integrity, ensuring every panel meets published load ratings.

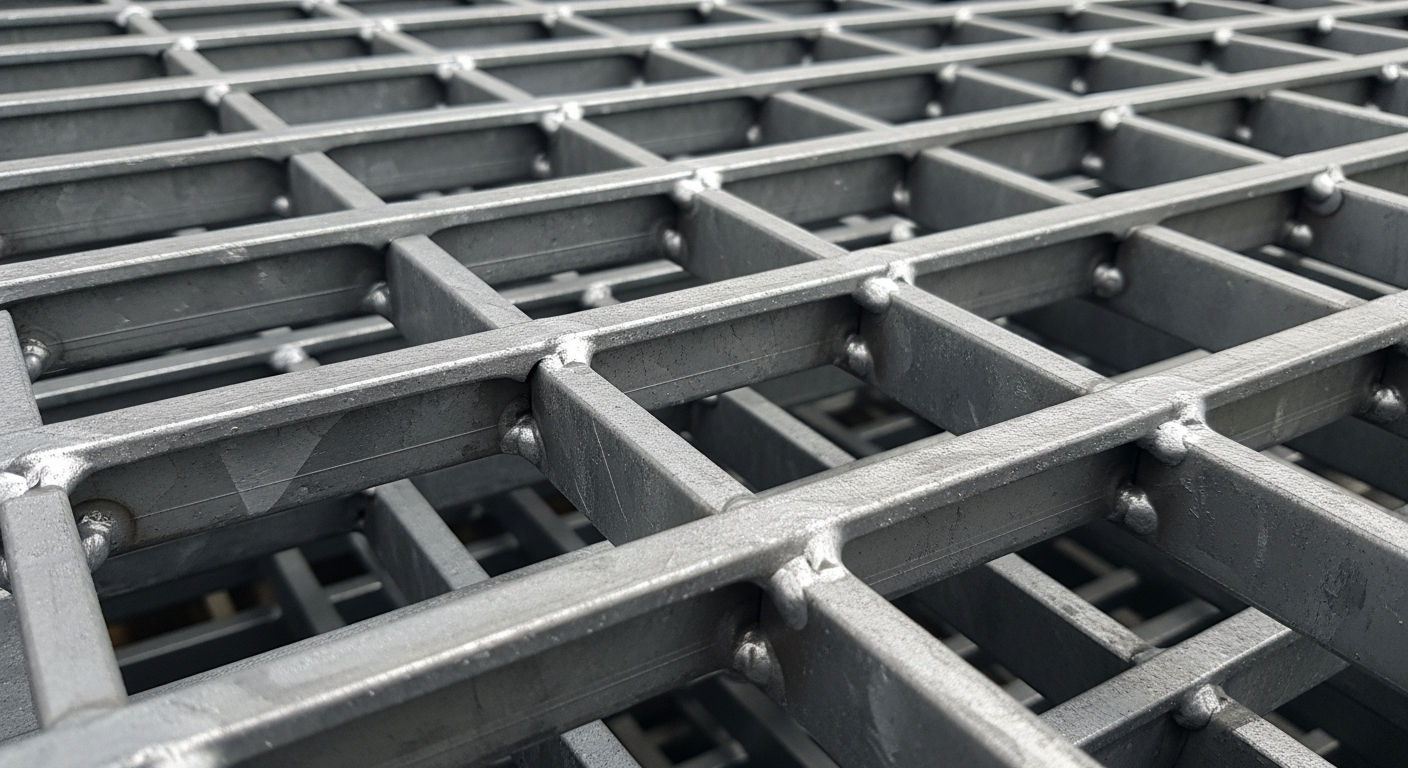

The Importance of Weld Integrity

The forge weld is the heart of welded bar grating's strength. A proper weld shows deep penetration and fusion between the cross rod and the bearing bar. A poor-quality weld is weak, inconsistent, and can pop under load, compromising the entire panel's integrity. Our quality system includes regular destructive testing, where we physically break sample welds to ensure they meet strength requirements.

Material Traceability and MTRs

How do you know the steel is ASTM A36 as specified? You ask for a Material Test Report (MTR). As part of our PPAP process, we maintain full traceability. We can track the finished grating panel you receive all the way back to the specific heat of steel it was made from at the mill. This guarantees that the material's chemical and mechanical properties are exactly what they should be.