PEEK vs POM: Which High-Performance Plastic Is Right for Your Application?

Your new design requires a high-strength plastic gear. POM (Acetal) is a reliable workhorse, but the operating temperature is pushing its limits. Is it time to make the massive cost jump to PEEK?

The choice between PEEK and POM is a clear engineering trade-off. POM is the go-to for high-performance mechanical parts at a reasonable cost, while PEEK is reserved for "extreme" applications where failure is not an option, justifying its significantly higher price.

¿Cuándo se justifica el costo de PEEK sobre POM?

POM is an excellent material, so when does it make financial and engineering sense to specify a polymer that can be 10, 20, or even 30 times more expensive?

The staggering cost of PEEK is justified only when the application involves extreme temperatures, harsh chemical exposure, or a combination of demanding factors where POM would physically degrade and fail.

El factor del rendimiento térmico

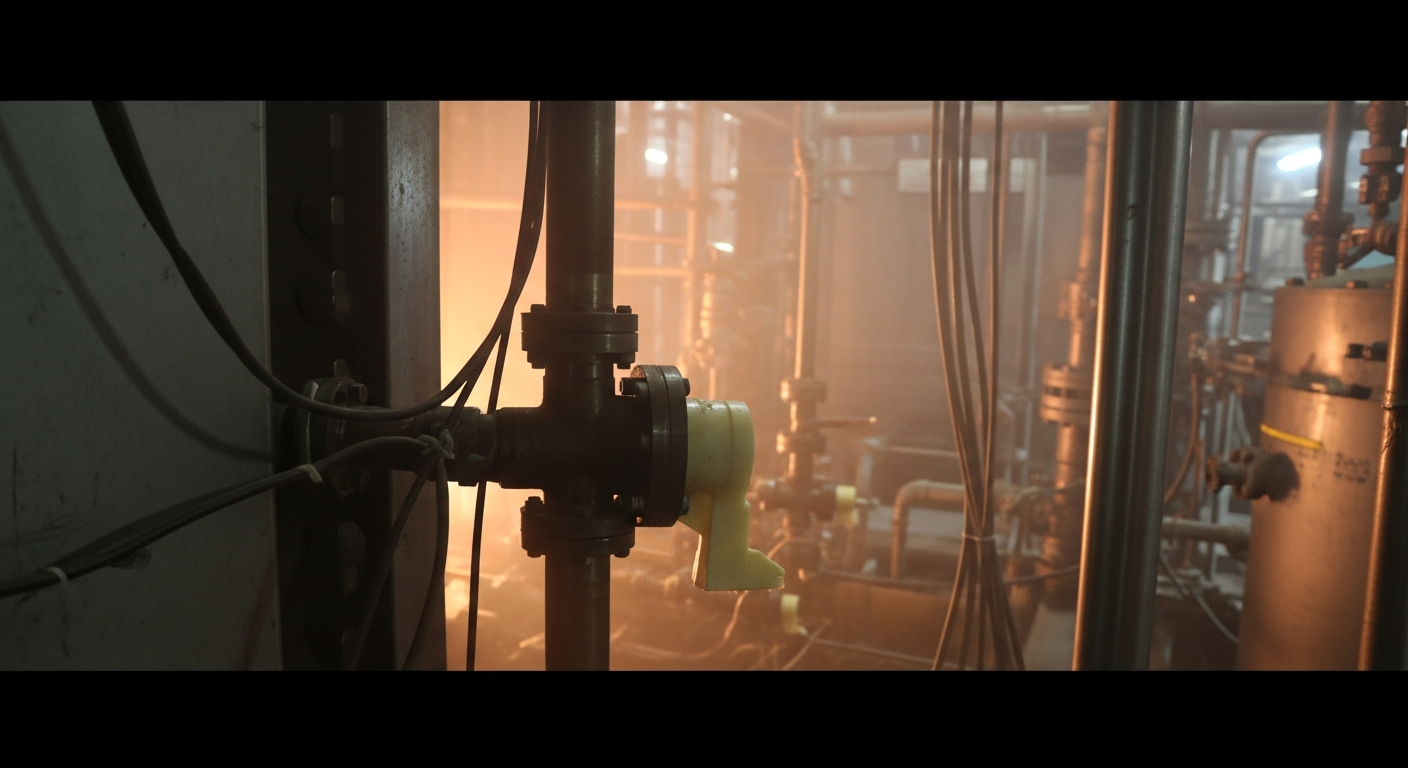

This is the single biggest differentiator. POM has a continuous service temperature of around 100°C (212°F). Above that, it starts to lose its mechanical properties rapidly. PEEK, on the other hand, can operate continuously at 250°C (482°F) and withstand short-term excursions even higher. If your part will see steam, autoclaves, or high-temperature engines, PEEK is your only option.

Resistencia química: El campo de batalla

POM has good resistance to many solvents and hydrocarbons. However, it is susceptible to attack by strong acids and bases. PEEK is virtually inert, with near-universal chemical resistance, comparable to that of PTFE but with far greater mechanical strength. For parts in chemical processing, oil and gas, or medical device sterilization, PEEK is the safer choice.

Análisis de costo-beneficio a largo plazo

Never evaluate material cost in a vacuum. A failed $50 POM part that shuts down a production line for a day can cost tens of thousands of dollars in lost revenue. A $500 PEEK part that runs flawlessly for years is, in that context, the far cheaper option. Your analysis must include the cost of failure.

| Feature | POM (Acetal / Delrin®) | PEEK (Polyetheretherketone) |

|---|---|---|

| Cost Index | $$ | $$$$$ |

| Continuous Temp. | ~100°C | ~250°C |

| Chemical Resistance | Good | Excellent (Near-universal) |

| Best For | General mechanical parts | Extreme environment parts |

Quelles sont les principales différences de performance mécanique?

Beyond heat and chemicals, how do these two materials stack up when it comes to strength, stiffness, and wear resistance?

While both are considered strong and rigid plastics, PEEK operates in a higher class of mechanical performance, especially in its glass-filled and carbon-filled grades, maintaining its properties at temperatures where POM would have already failed.

Résistance à la traction et rigidité

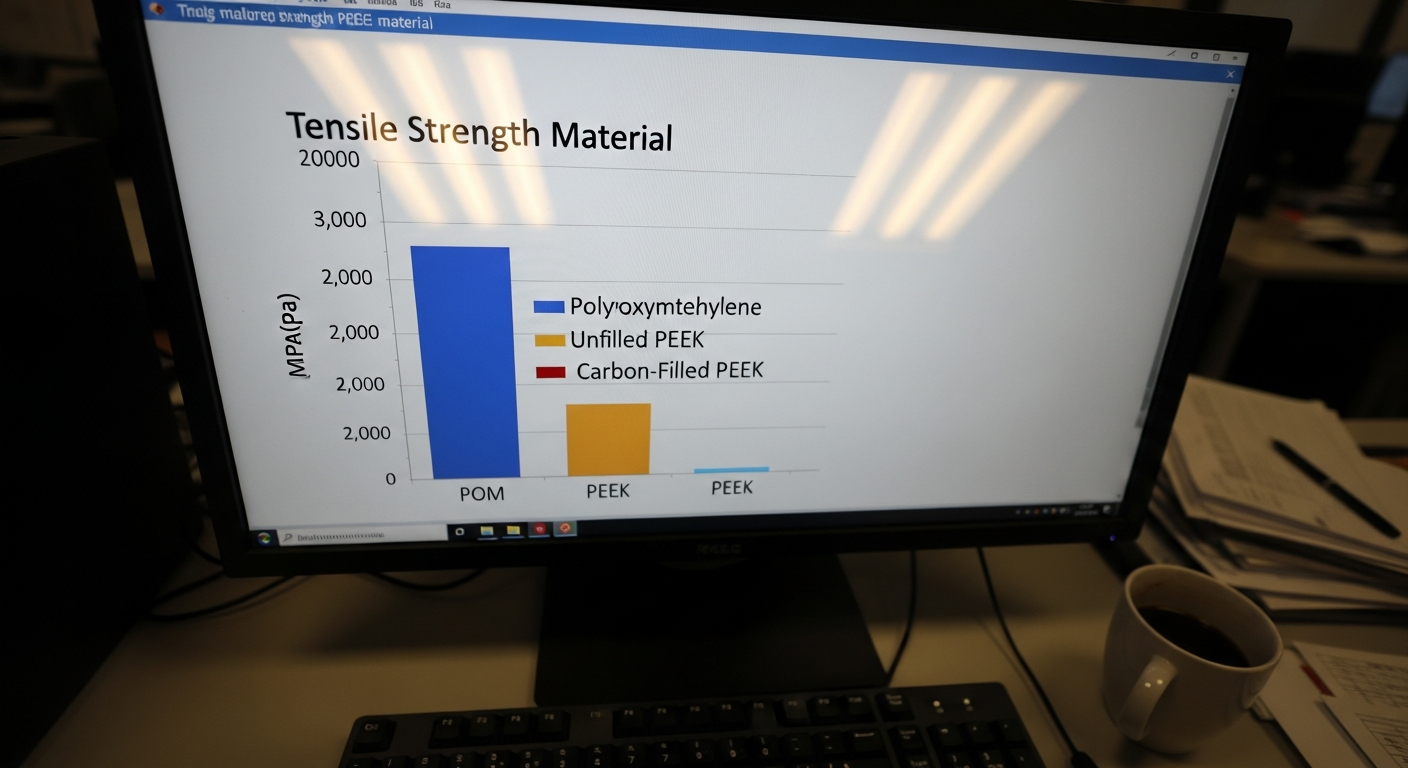

Standard POM (copolymer) has a tensile strength of around 65 MPa. The homopolymer version, DuPont™ Delrin®, is slightly stronger at around 70 MPa. Unfilled PEEK starts significantly higher at about 100 MPa. When you move to reinforced grades like 30% carbon-filled PEEK, the tensile strength can exceed 200 MPa, putting it in the territory of some aluminum alloys. For more data, major suppliers like Solvay Specialty Polymers offer extensive datasheets.

Performance en matière de fatigue et d'usure

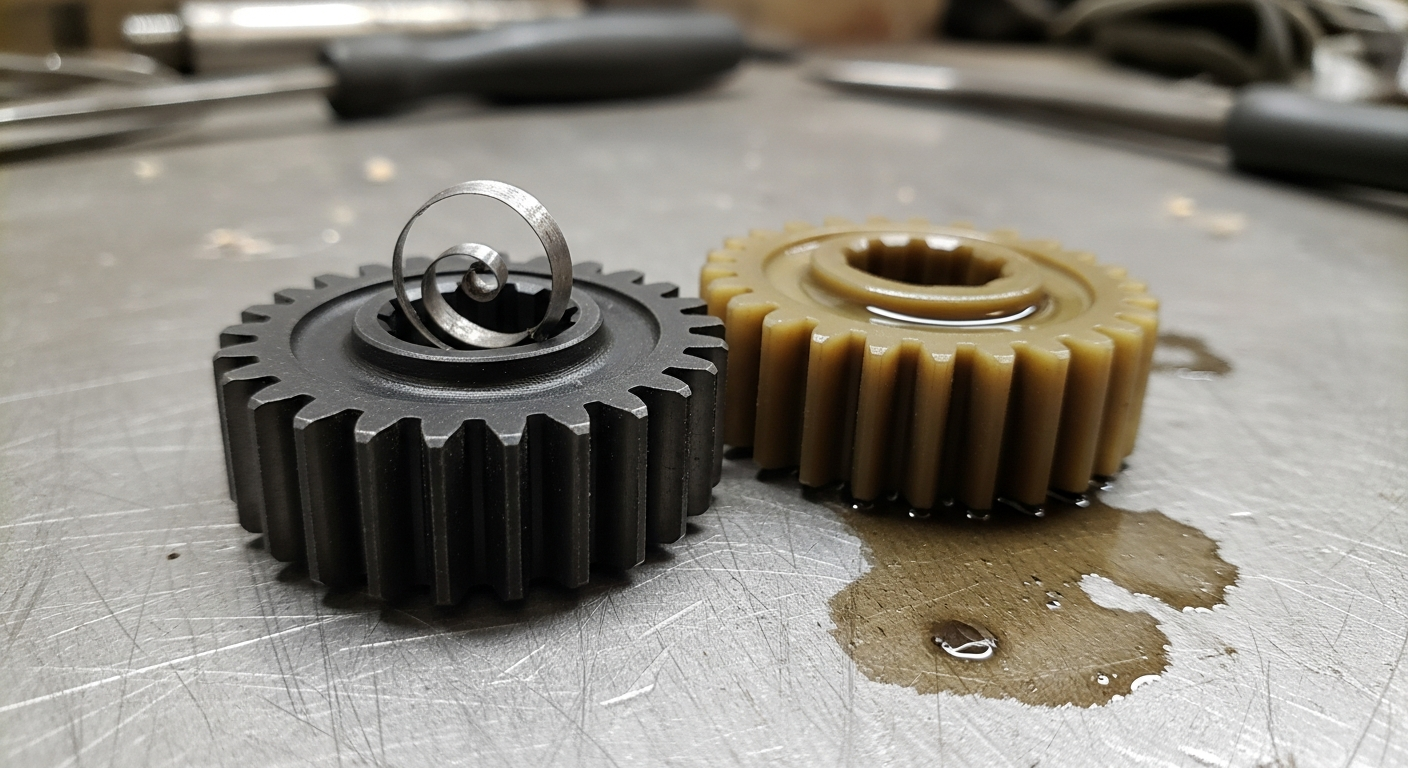

This is where the comparison gets interesting. POM, especially Delrin®, has an exceptionally low coefficient of friction and excellent natural lubricity. This makes it one of the best materials available for wear applications like gears and bushings, offering incredible performance for its cost. Bearing-grade PEEK (with carbon fiber and other fillers) is also a top-tier wear material, but its key advantage is performing in high-temperature wear applications where POM could not survive. For room-temperature wear parts, POM often provides the best value.

Stabilité dimensionnelle et absorption d'humidité

Both materials are known for excellent dimensional stability. They have very low moisture absorption compared to materials like Nylon. This means parts made from PEEK or POM will not swell or change size in humid environments, making them ideal for high-precision components. This is a critical factor for