Why Is a Plastic's Melting Point So Critical for Injection Molding?

You've approved a design for a new plastic enclosure. Six weeks later, the first samples arrive, but they're warped, brittle, and have ugly surface marks. What went wrong?

A plastic's melting point is the master variable in injection molding. It dictates the exact processing temperature, which in turn controls the material's flow, the final part's strength, its dimensional stability, and its ability to perform in its end-use environment.

I've been dealing with metal and plastic parts for over thirty years, and I can tell you that most plastic part failures begin with a misunderstanding of this single property. A client once specified a polycarbonate for a housing that sat near a small motor. They looked at the melting point and thought it was high enough. What they failed to consider was the Heat Deflection Temperature, and their parts began to sag and deform in the field. Understanding the nuances isn't just academic; it prevents costly failures and recalls.

What Does "Melting Point" Actually Mean for Plastics?

Unlike an ice cube that melts at a precise temperature, the term "melting point" for plastics is more complex. Is it the point it turns to liquid? The point it gets soft?

For plastics, there isn't one single melting point. Instead, there's a "processing window." The exact nature of this window depends on whether the plastic is crystalline or amorphous, which are two fundamentally different molecular structures.

Crystalline vs. Amorphous: A Critical Distinction

This is the most important concept to grasp.

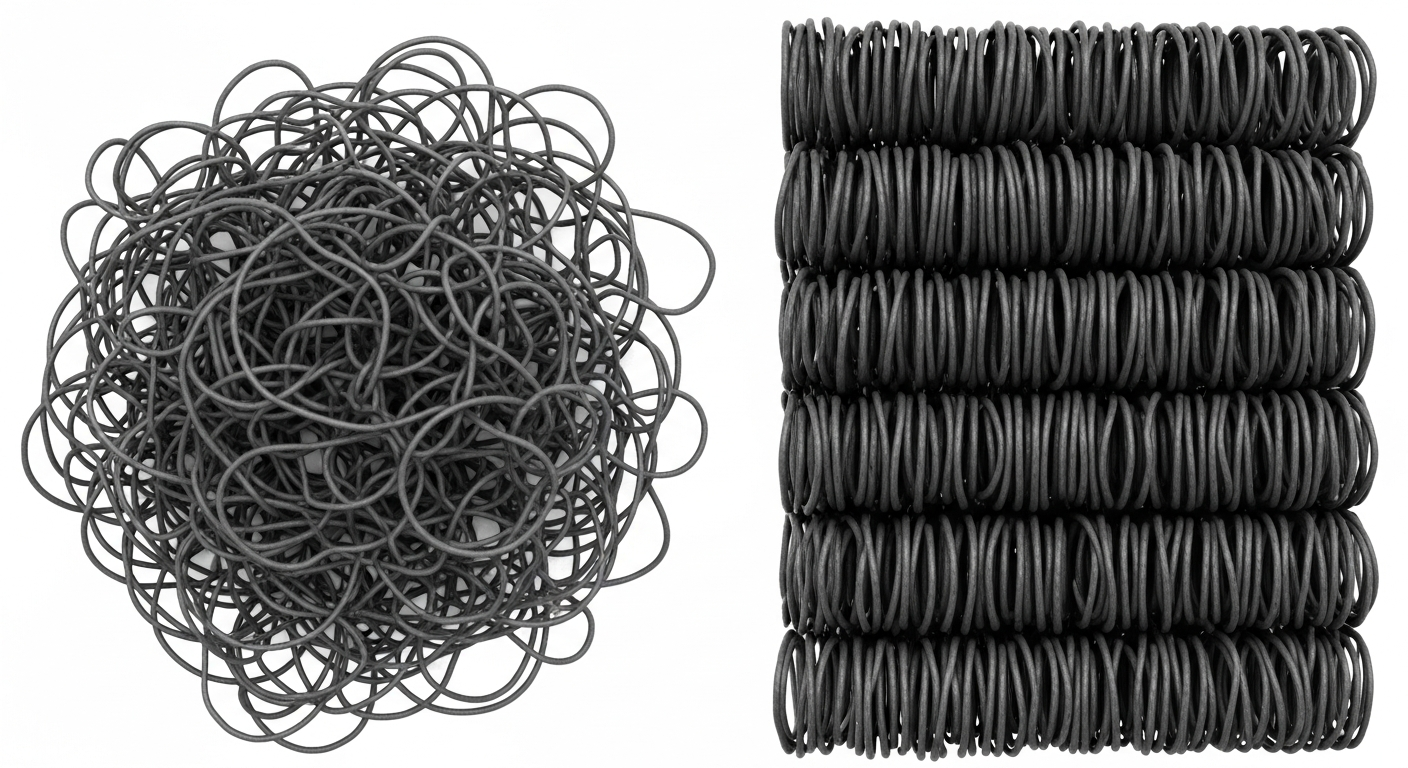

- Crystalline Plastics (like Nylon, Polypropylene) have an ordered, packed molecular structure. They have a sharp, well-defined melting point (Tm) where the solid structure breaks down into a low-viscosity liquid.

- Amorphous Plastics (like ABS, Polycarbonate) have a random, tangled molecular structure. They don't have a true melting point. Instead, they have a Glass Transition Temperature (Tg) where they go from a rigid, glassy state to a soft, rubbery one, gradually becoming more liquid as heat increases. You can learn more about this concept on the Wikipedia page for Glass Transition.

The "Processing Window"

This is the temperature range where the plastic is molten enough to be injected but not so hot that it begins to degrade or burn. For crystalline plastics, this window can be quite narrow. For amorphous plastics, it's generally wider. Operating outside this window, even by a few degrees, is the primary cause of cosmetic and structural defects.

Beyond Melting: Heat Deflection Temperature (HDT)

The HDT is often more important for product designers than the melting point. It's the temperature at which a plastic sample deforms under a specific load. This simulates how your product will behave in the real world when it gets hot while still carrying weight or being under tension. A high melting point does not always guarantee a high HDT.

How Does Melting Point Guide the Injection Molding Process?

The material datasheet provides the melting range, but how do we translate that into a successful manufacturing run on the factory floor?

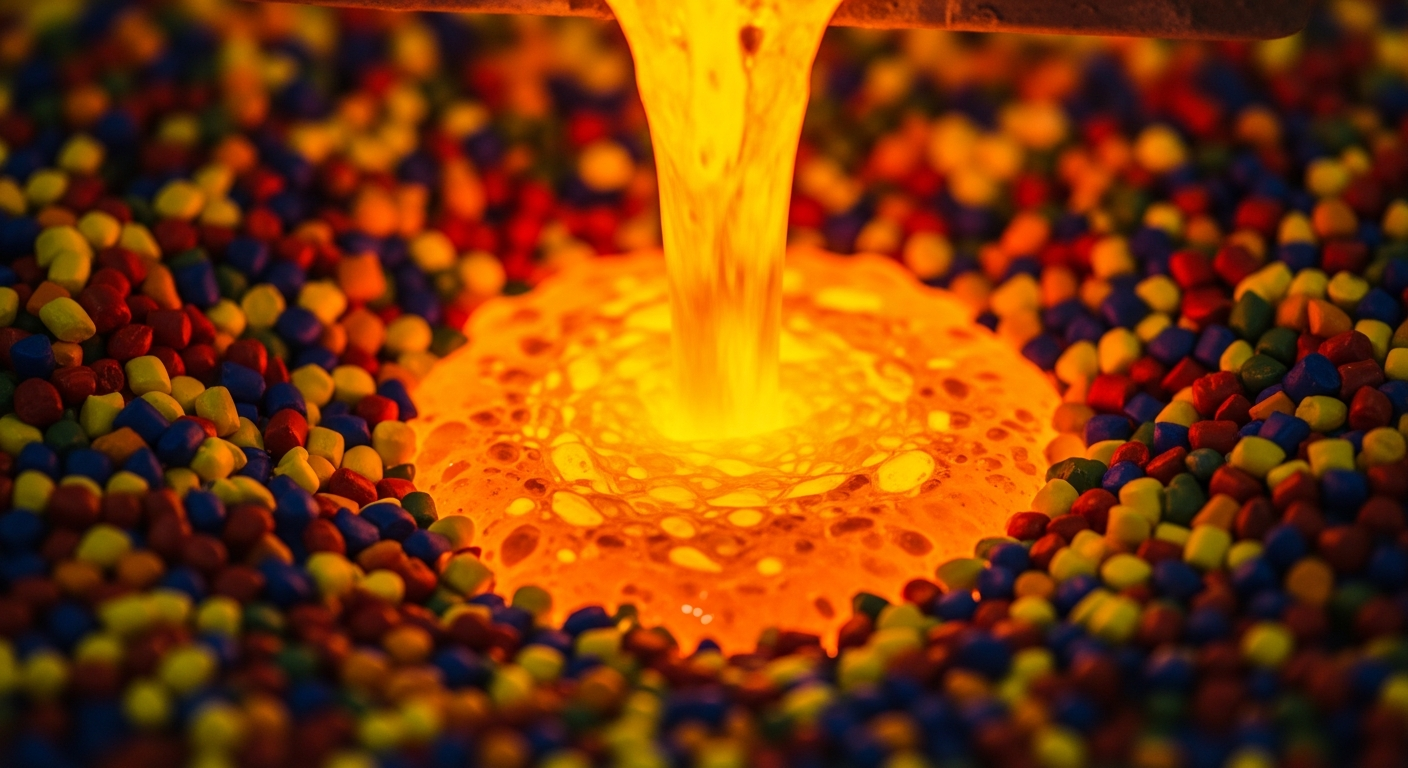

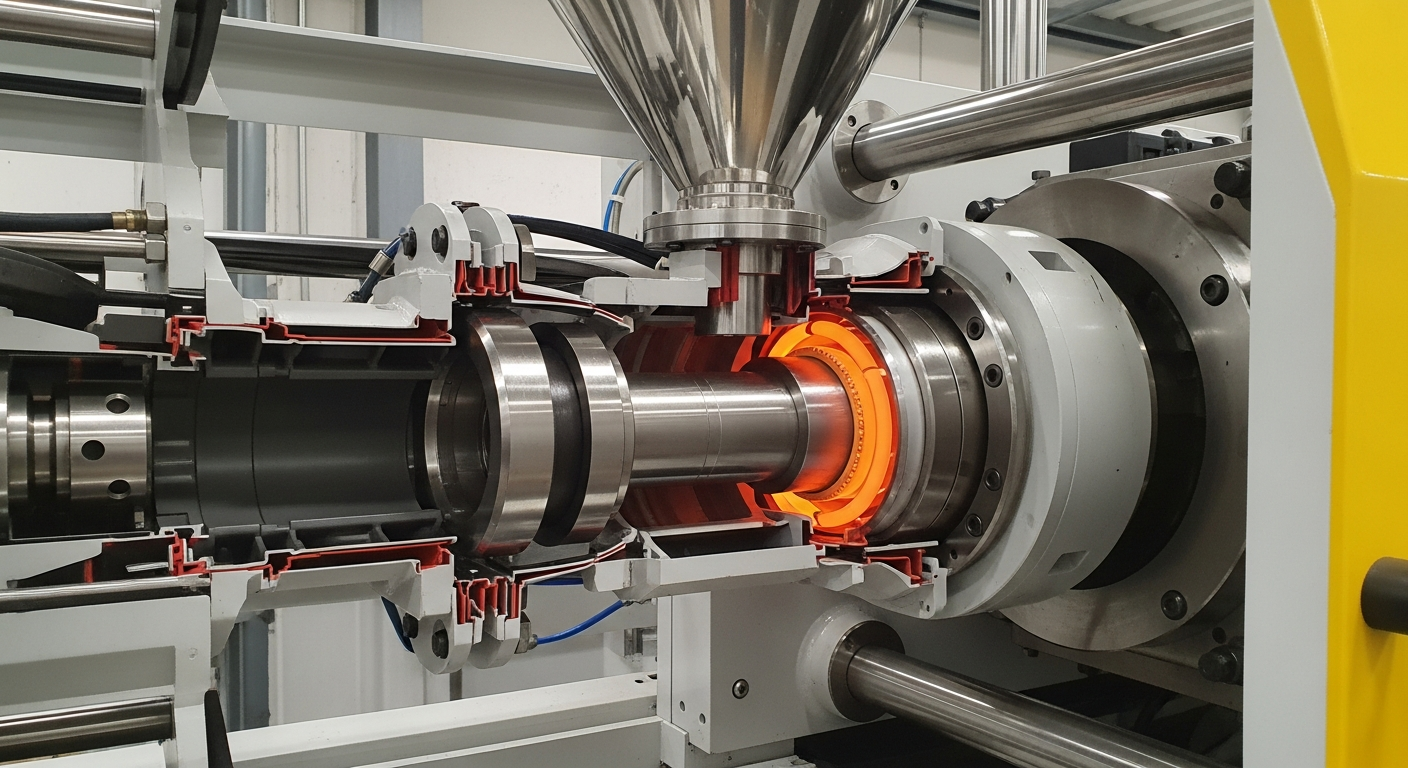

The plastic's melting point is the roadmap for setting up the entire injection molding machine. It directly dictates the barrel temperature profile, influences injection speed and pressure, and determines the required mold temperature and cooling time.

Setting Barrel Temperatures

An injection molding machine doesn't have one temperature; it has a series of heating zones along its barrel. We set these zones in a specific profile, starting cooler at the back where the pellets enter and getting progressively hotter toward the nozzle. This gradual heating ensures the plastic is melted uniformly and consistently, without being burned. A high-melt-point plastic like PEEK requires much higher barrel temperatures than a commodity plastic like Polypropylene.

Controlling Flow Rate and Pressure

The temperature of the molten plastic directly affects its viscosity (its thickness or resistance to flow). A hotter melt flows more easily, allowing us to fill complex, thin-walled parts of a mold with lower injection pressure. This is a delicate balance. Too hot, and the material can flash (leak out of the mold seams); too cold, and it won't fill the mold completely, resulting in a "short shot."

Mold Temperature and Cycle Time

The mold is also heated or cooled to a specific temperature. High-temperature plastics often require a very hot mold to prevent the molten plastic from freezing too quickly, which can cause internal stresses and weak points. However, a hotter mold means a longer cooling time is needed before the part can be ejected. This directly increases the cycle time and the cost-per-part, a critical factor for any buyer to consider.

What Are the Melting Points of Common Industrial Plastics?

When you're choosing a material, knowing the general hierarchy of thermal performance is essential. You don't need to memorize exact numbers, but you should know the difference between a commodity, engineering, and high-performance polymer.

Plastics can be grouped into tiers based on their melting points and thermal performance. Commodity plastics like Polypropylene have low melting points, while high-performance plastics like PEEK can require processing temperatures hotter than some metals.

Plastic Melting and Processing Temperature Chart

This chart provides a general guide. Always consult the specific manufacturer's datasheet for the exact grade you are using.

| Plastic Type | Name & Abbreviation | Typical Melting Point (Tm or Tg) | Typical Processing Temp. | Key Characteristics |

|---|---|---|---|---|

| Commodity | Polypropylene (PP) | 160 °C (320 °F) | 200-250 °C (392-482 °F) | Low cost, chemical resistance, flexible. |

| Commodity | Polyethylene (HDPE) | 130 °C (266 °F) | 180-240 °C (356-464 °F) | Very low cost, tough, excellent chemical resistance. |

| Engineering | ABS | 105 °C (221 °F) (Tg) | 210-240 °C (410-464 °F) | Good impact strength, easy to process, great finish. |

| Engineering | Nylon 6/6 (PA66) | 265 °C (509 °F) | 275-300 °C (527-572 °F) | High strength, wear resistance, absorbs moisture. |

| Engineering | Polycarbonate (PC) | 150 °C (302 °F) (Tg) | 280-310 °C (536-590 °F) | Extremely high impact strength, transparent. |

| High-Performance | PEEK | 343 °C (649 °F) | 360-400 °C (680-752 °F) | Extreme heat/chemical resistance, metal replacement. |

What Happens When the Processing Temperature Is Wrong?

Minor deviations from the ideal processing window don't just affect appearance; they can create hidden structural flaws that cause parts to fail unexpectedly.

Processing plastic too hot causes permanent chemical degradation, making it brittle and weak. Processing it too cold results in incomplete mold filling and creates weak points where molten plastic fronts fail to merge properly.

The Danger of "Too Hot": Material Degradation

When a plastic is overheated, its long polymer chains are literally broken apart. This is called thermal degradation. The material may look discolored (yellowed or browned) or have black specks from burned particles. More importantly, its mechanical properties—like impact strength and flexibility—are permanently destroyed. The part will be brittle and can fail under minimal stress.

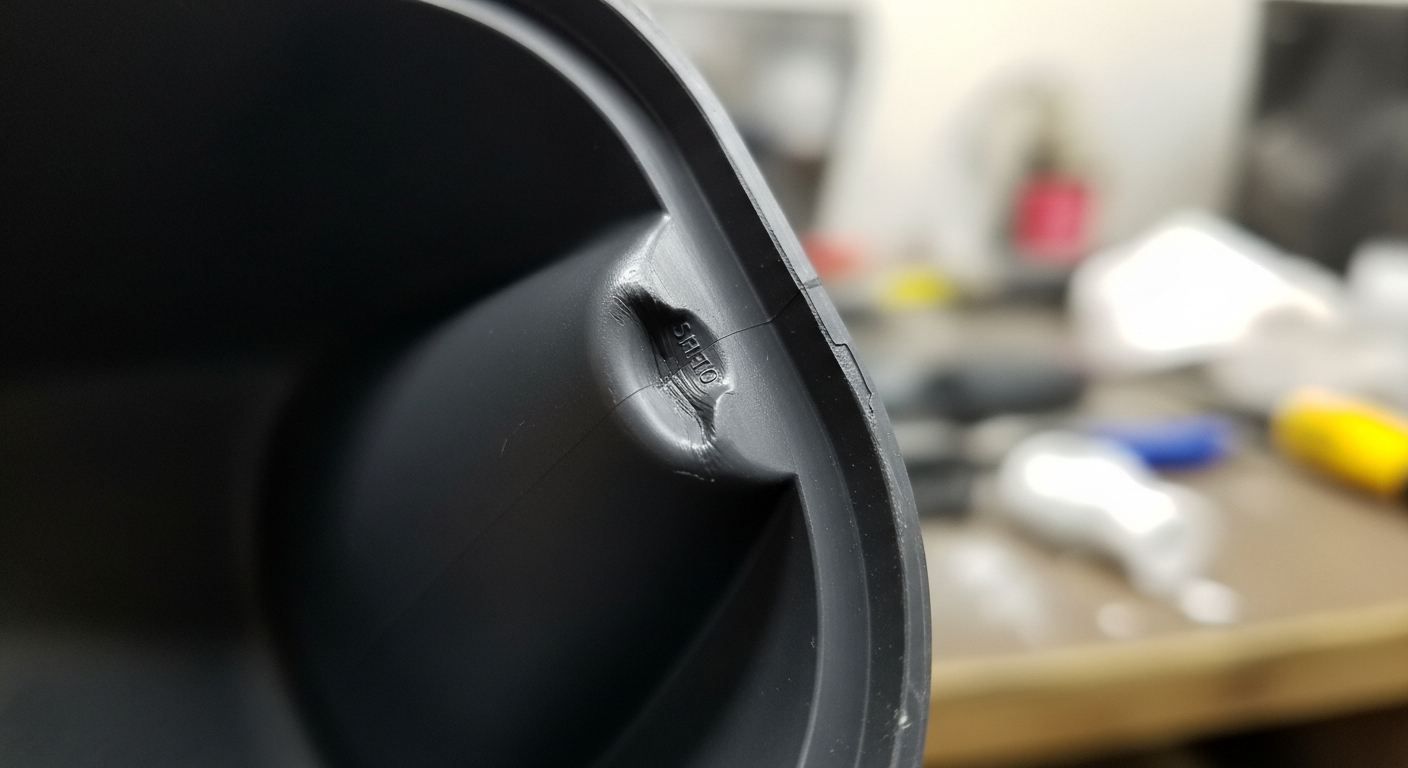

The Problem of "Too Cold": Short Shots and Weld Lines

If the melt is too cool, its viscosity is too high. It may not have enough energy to fill the entire mold cavity before it solidifies, causing a "short shot." Even if it does fill, where two fronts of molten plastic meet and merge, they may be too cool to fuse together perfectly. This creates a "weld line," which is a visible line on the part's surface that is also a significant structural weak point.

Hidden Flaws: Internal Stress and Warping

Correct temperature control, including the mold temperature, is vital for managing how the part cools. If a part cools too quickly or unevenly, internal stresses are locked into its structure. The part may look fine when it comes out of the machine, but hours or days later, these stresses can relieve themselves, causing the part to warp, twist, or crack. Our PPAP process for customers often includes long-term dimensional stability checks to prevent this.

How Do You Ensure the Right Material and Process Are Used?

As a buyer, you can't be on the factory floor for every production run. So how do you ensure your supplier is using the specified material and processing it correctly?

Verification comes from a quality system based on documentation and traceability. This includes demanding a Certificate of Conformance (CoC) for the raw material and partnering with a supplier who is ISO 9001 certified.

Trust the Material Datasheet

The technical datasheet (TDS) from the material manufacturer is the single source of truth. It lists all the critical properties, including the recommended processing window for melting temperature, mold temperature, and even drying time (many plastics must be dried before molding). We always have the TDS on file for every material we run.

Material Traceability is Non-Negotiable

Our ISO 9001 system requires us to have complete traceability. When a shipment of raw material arrives, it is assigned a lot number. That lot number is tracked from the warehouse, to the dryer, to the specific machine it's used on. We can trace any single part we've produced back to the exact bag of raw material it came from. This guarantees you are getting the material you paid for.

Process Parameter Documentation

For every part we mold, we create a setup sheet that documents all the critical machine parameters: every barrel temperature, the injection pressure, cooling time, and more. This ensures that the first part we make and the ten-thousandth part are made under the exact same, optimized conditions. This documentation is a core part of our quality promise for all our services, from plastics to stamping parts.

About the Author

My name is Kevin. I'm the founder of Prime, and I've spent my career on both sides of the procurement table. I started this company in 1993 because I saw a need for a manufacturing partner who understood the engineering behind the parts they made. We don't just mold plastic; we build reliable components by mastering the science of materials and processes.

Frequently Asked Questions (FAQs)

What is the difference between Melting Point (Tm) and Glass Transition Temperature (Tg)?

Melting Point (Tm) applies to crystalline plastics and is a sharp transition where the material becomes a true liquid. Glass Transition Temperature (Tg) applies to amorphous plastics and is the point where the material shifts from a rigid solid to a soft, workable state, without becoming a true low-viscosity liquid.

How does adding glass fiber affect a plastic's melting point?

Adding glass fiber reinforcement does not significantly change the plastic's melting point (Tm or Tg). However, it dramatically increases the Heat Deflection Temperature (HDT), allowing the part to remain rigid and bear loads at much higher temperatures.

Can you injection mold recycled plastic?

Yes, many thermoplastics can be recycled and remolded. However, each heating cycle can cause some minor degradation, potentially lowering the material's performance. It's critical to know the history of the recycled material and to blend it with virgin material to maintain consistent properties.

From Molten Plastic to Perfect Part

A plastic's melting point is far more than a number on a spec sheet. It's the foundational parameter that dictates how your part is made and how it will perform. Understanding its importance is the first step toward preventing defects, controlling costs, and ensuring your final product is a success.

Let our expertise in materials and processes guide your next project.