What is a busbar and why is it essential in electrical power distribution?

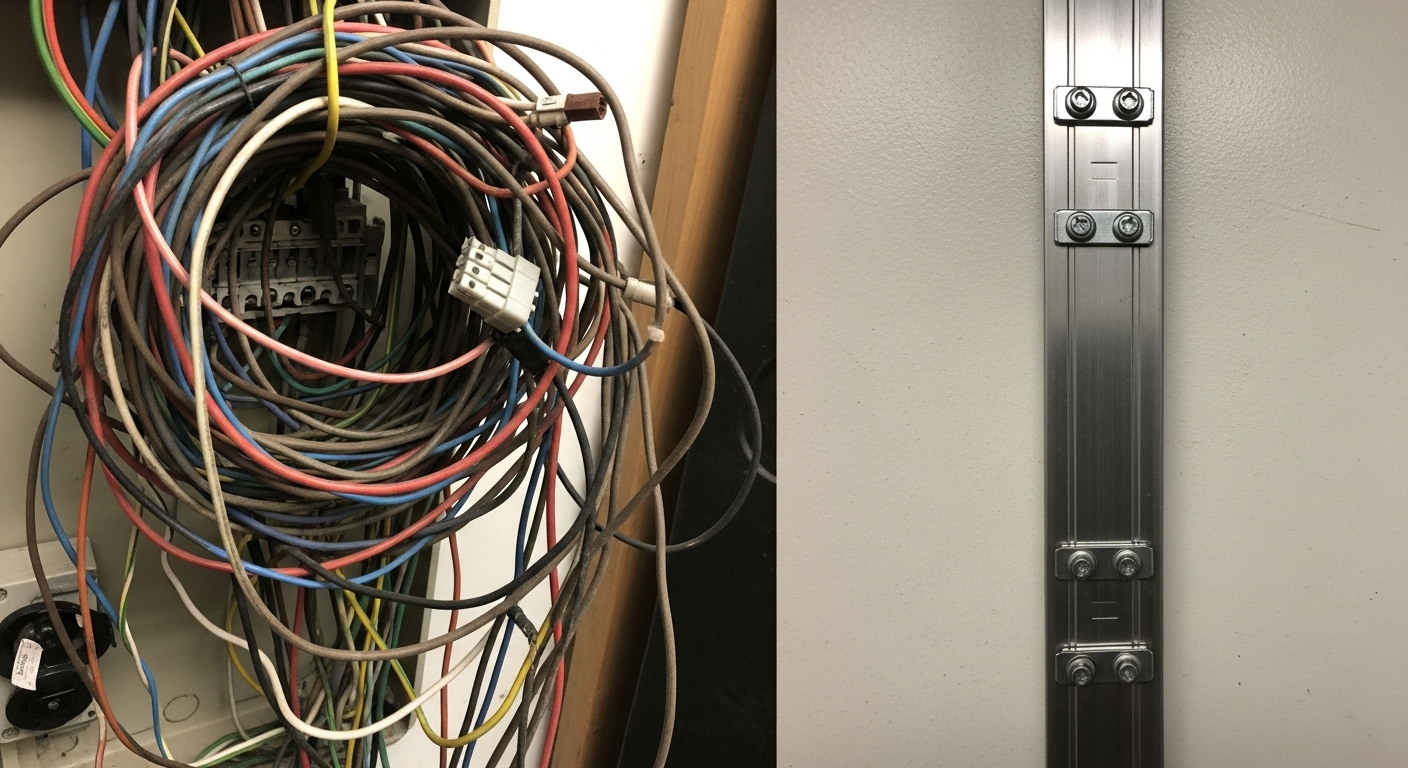

Have you ever opened an electrical cabinet to find a chaotic mess of thick, heavy cables? This "rat's nest" is inefficient, difficult to service, and a potential point of failure just waiting to happen.

A busbar is a rigid metallic strip, typically made of copper or aluminum, that serves as a centralized conductor to collect and distribute high-current electrical power. It replaces multiple individual cables with a single, efficient, and structurally sound component.

In my early days as a buyer, I saw projects delayed and budgets blown because of complex wiring schemes. The solution was often a simple, elegant component I came to respect deeply: the busbar. Now, at Prime Metals, we manufacture these critical components, and I see from the factory floor how they are the unsung heroes of modern power systems. They are not just strips of metal; they are the engineered backbone of safe and reliable power distribution.

What materials are used for busbars and how do they compare?

Choosing the wrong material for a busbar isn't a small mistake. It can lead to overheating, dangerous voltage drops, and premature system failure. The choice between copper and aluminum is the first and most critical decision.

Busbars are almost exclusively made from high-conductivity copper (C11000) or aluminum (6061/6101 series). Copper is the superior choice for conductivity and durability, while aluminum offers a lower cost and weight advantage.

Copper: The High-Performance Standard

Electrolytic Tough Pitch (ETP) Copper, specifically alloy C11000, is the gold standard for busbars. Its primary advantage is its excellent electrical conductivity, second only to silver. This means for a given amount of current, a copper busbar can be smaller than an aluminum one. It is also strong, resists corrosion well (especially when plated), and handles thermal expansion reliably.

Aluminum: The Cost-Effective Alternative

Aluminum alloys, like 6101, are a popular alternative. Their main benefit is a much lower cost and a significantly lighter weight (about 70% lighter than copper for the same volume). However, aluminum's conductivity is only about 61% of copper's. This means that to carry the same current (ampacity), an aluminum busbar must have a larger cross-sectional area.

Plating: The Essential Protective Layer

Bare copper and aluminum can oxidize over time, especially at connection points. This oxide layer increases electrical resistance, causing heat and potential failures. To prevent this, we often plate busbars with tin, silver, or nickel. Tin plating is the most common as it provides excellent corrosion resistance and solderability at a reasonable cost.

| Feature | High-Conductivity Copper (C110) | Electrical Grade Aluminum (6101) |

|---|---|---|

| Conductivity (IACS) | 101% | ~61% |

| Cost | Higher | Lower |

| Weight | Heavier | Lighter |

| Strength | High | Moderate |

| Corrosion Resistance | Good (Excellent when plated) | Fair (Excellent when plated) |

How are busbars manufactured to ensure safety and precision?

A busbar isn't just a raw strip of metal. It's a precisely engineered component. The manufacturing process must be tightly controlled to guarantee its performance and, more importantly, its safety under high electrical loads.

Busbars are manufactured through a series of precision processes including CNC punching or machining for connection holes, CNC bending to create specific forms, and applying insulation or plating for electrical safety and corrosion resistance.

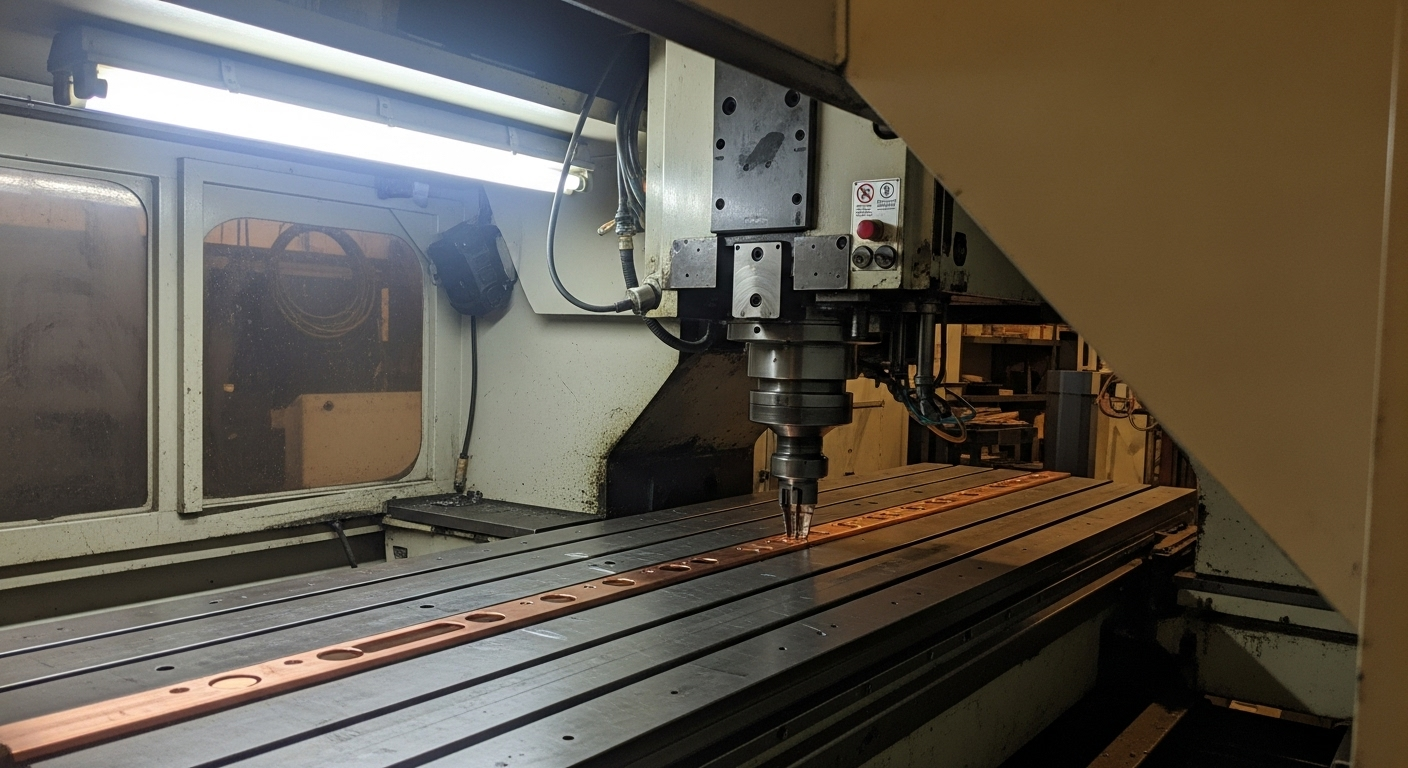

CNC Punching and Bending

For a busbar to fit perfectly into a panel or battery pack, every hole and bend must be exact. We use our advanced CNC machining and stamping capabilities to achieve this. A CNC punch press creates clean, burr-free holes for connections, while a CNC press brake bends the bar into complex 3D shapes, all with tight tolerances that ensure a perfect fit every time.

Insulation and Safety

In many applications, busbars must be insulated to prevent accidental short circuits. This is typically done with heat-shrink tubing or an electrostatically applied powder coating. These coatings provide excellent dielectric strength (the ability to withstand voltage) and are a critical safety feature, governed by standards like those from the National Electrical Manufacturers Association (NEMA).

Quality Control and Testing

Every busbar we produce undergoes rigorous quality checks. This starts with dimensional verification using CMMs or digital calipers against your drawing. Critically, for insulated busbars, we perform a dielectric withstand test (or "hi-pot" test) which applies a high voltage to the bar to ensure the insulation is free of any pinholes or defects. This is a core part of our ISO 9001 certified process.

How do busbars improve upon traditional wiring cables?

Why go through the effort of designing and manufacturing a custom busbar when you could just use a thick wire? This is a question I hear from new engineers, and the answer lies in performance, reliability, and efficiency.

Busbars are manufactured through a series of precision processes including CNC punching or machining for connection holes, CNC bending to create specific forms, and applying insulation or plating for electrical safety and corrosion resistance.

Superior Heat Dissipation

Heat is the enemy of electrical systems. A busbar's flat, wide shape gives it a much larger surface area than a round cable with the same current-carrying capacity. This allows heat to radiate away more effectively, letting the conductor run cooler and more efficiently.

Simplified Assembly and Reliability

Connecting ten separate devices to a power source with cable requires twenty crimped lugs and twenty bolted connections. A busbar can do the same job with just eleven connection points. Fewer connections mean fewer potential points of failure, reduced labor time for assembly, and a much cleaner, more serviceable layout.

Space Efficiency and Rigidity

Busbars are rigid and can be designed to fit precisely into tight spaces where flexible cables would be difficult to route. They are self-supporting, eliminating the need for complex cable trays and ties. This results in a smaller, lighter, and more professional-looking electrical assembly.

What are the different types of busbars for different applications?

Not all busbars are simple flat strips. As technology evolves, especially in areas like electric vehicles and renewable energy, specialized busbars have been developed to meet new challenges in power distribution.

While flat bars are most common, busbars come in various forms, including multi-layered laminated busbars for high-frequency applications, and flexible braided busbars for connecting components that vibrate or move.

Flat Strip Busbars

This is the most common type you'll see in switchgear, panelboards, and industrial equipment. They are cost-effective, easy to manufacture, and highly versatile. We can produce these simple but essential components in any configuration you need, from a simple link to a complex multi-bend distributor.

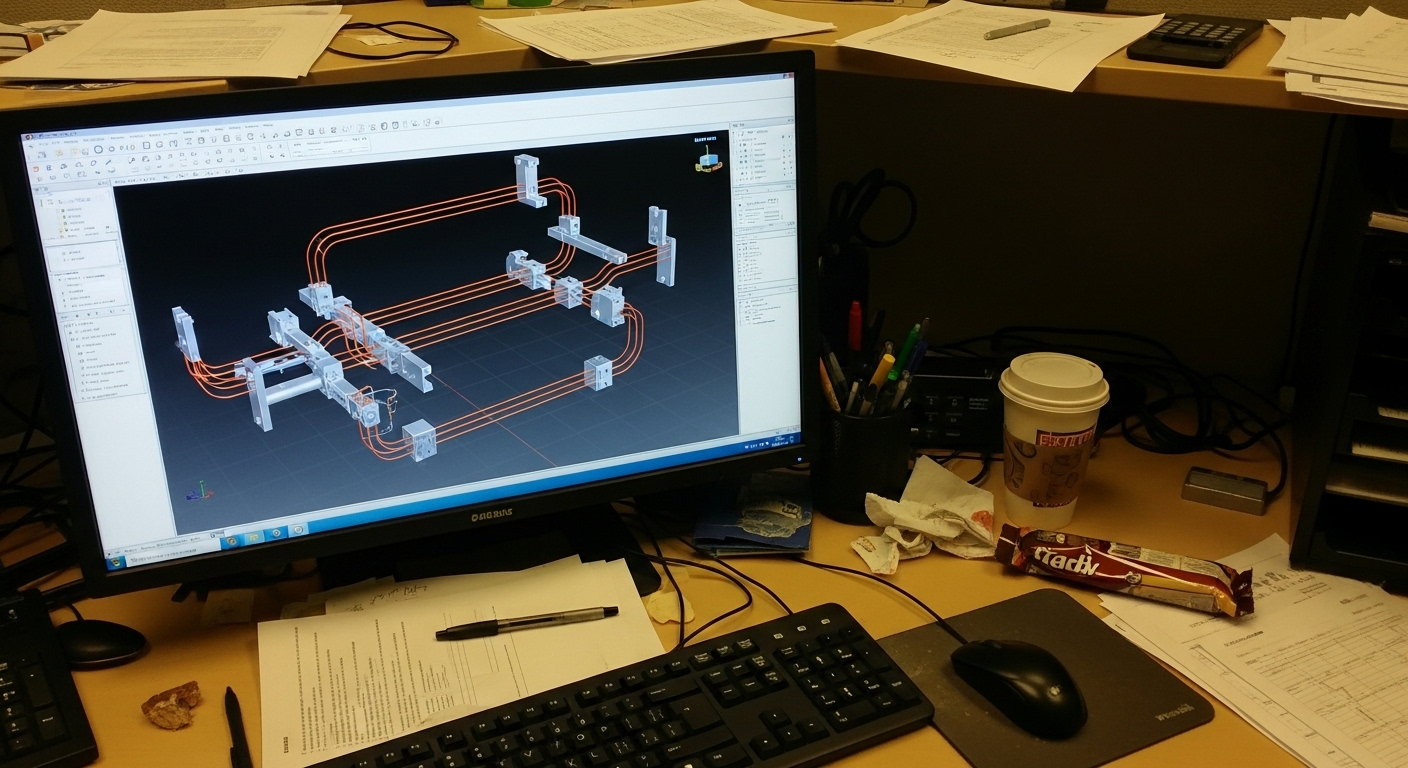

Laminated Busbars

A laminated busbar is an engineered component consisting of multiple layers of thin copper or aluminum conductors, separated by thin dielectric materials and laminated into a single, unified structure. As explained by sources like Wikipedia, they are critical in modern power electronics (like EV inverters) for their ability to reduce inductance and manage high-frequency currents.

Flexible Busbars

These are made from stacked layers of thin copper foil or fine-wire copper braids. They offer the current-carrying capacity of a solid bar but with the flexibility of a cable. They are perfect for applications that require vibration damping or connecting two points that may shift or misalign, such as connecting a transformer to a distribution panel.

What design considerations are critical for a custom busbar?

A well-designed busbar is a work of art; a poorly designed one is a fire hazard. There are several key factors that we, as your manufacturing partner, need to see clearly defined on your print to create a safe and effective part.

Critical design considerations for a custom busbar include calculating the correct cross-sectional area for the required ampacity, defining precise hole locations and sizes for connections, and ensuring bend radii are manufacturable to prevent stress cracking.

Ampacity and Cross-Sectional Area

"Ampacity" is the maximum current a conductor can carry continuously without exceeding its temperature rating. This is a function of the busbar's material and its cross-sectional area (thickness x width). You must engineer this correctly; an undersized bar will overheat and fail.

Connection Points and Hardware

The location, size, and number of holes are critical. These define how your busbar interfaces with circuit breakers, batteries, or other components. You should also consider the hardware (bolts, nuts, washers) that will be used and ensure there is adequate clearance for tooling.

Manufacturability: Bend Radii and Tolerances

Every bend in a busbar has a minimum inside radius to prevent the material from cracking on the outside edge or buckling on the inside. Specifying a radius that is too sharp makes the part impossible to manufacture safely. Working with us early in the design process can help you optimize for manufacturability and lower costs. Need help with a design? Contact our team.

About the Author

My name is Kevin. My career began in the States, managing supply chains for large-scale electrical and industrial projects. I learned firsthand that component failure is often design failure. Since founding Prime Metals in 1993, I have instilled a culture of engineering partnership. We don't just make parts; we help you design and build reliable systems from the ground up.

Frequently Asked Questions (FAQs)

What is "ampacity"?

Ampacity, or ampere capacity, is the maximum amount of electrical current a conductor or device can carry continuously under the conditions of use without exceeding its temperature rating. It is the most critical specification for a busbar.

Why are busbars almost always flat and rectangular?

A rectangular shape has a larger surface-area-to-cross-sectional-area ratio compared to a round wire. This allows a busbar to dissipate heat into the surrounding air much more efficiently, which is crucial for high-current applications.

What is the difference between a busbar and a terminal block?

A busbar is designed to distribute high currents to multiple points along its length. A terminal block is primarily designed to terminate and connect multiple lower-current wires together at a single point, acting more like a junction than a distributor.

Can busbars be used for both AC and DC systems?

Yes, busbars are fundamental components in both Alternating Current (AC) systems (like building electrical panels) and Direct Current (DC) systems (like battery packs, EV powertrains, and solar power installations). The design considerations for high-frequency AC may differ slightly due to the skin effect.

The Backbone of Your Power System

From a simple switchboard to a complex electric vehicle, busbars are the essential components that make safe, efficient power distribution possible. They reduce complexity, improve reliability, and provide the structural foundation for your electrical systems.

Don't let complex wiring compromise your design. Let us help you engineer a custom busbar solution.